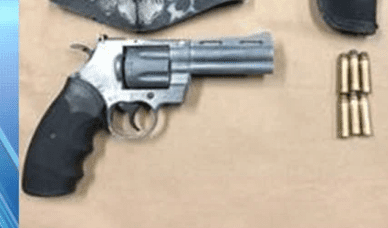

The Bakersfield Police Department is reporting that they arrested a felony parolee who was “in possession of an airsoft gun that had been converted to fire .357-caliber ammunition and had six live rounds of live ammunition”

One more time…an airsoft handgun…converted to fire .357 ammo.

From the police image above, that appears to be this 937 UHC toy; a plastic, 6mm revolver, with the orange tip removed.

I am…a little dubious. I think I could convert that toy into a single-shot handgun easily enough; though I would limit it to .38 Special, not .357 Magnum as implied by “.357-caliber ammunition.” With a lot more effort, maybe a repeating revolver. But doing either while preserving the original appearance would result in something which I would not fire even with your hand.

Perhaps I am underestimating the ease of converting cheap, plastic, 6mm airsoft knock-offs to fire live ammunition. Highly trained, professional ATF agent, Kelven Crenshaw, believes it can be done, even if he is a bit vague on how to insert a magazine.

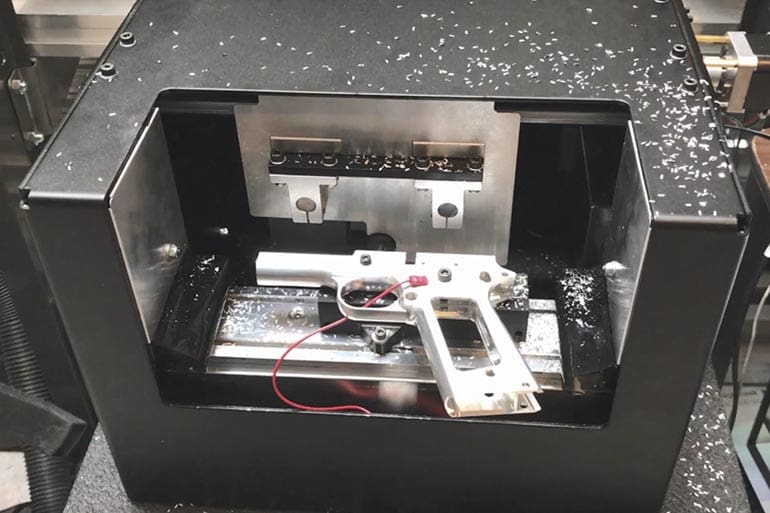

Should this report be accurate, it raises questions about the future market for 3D printed “ghost guns,” and 80% frames and receivers. Why go to all that effort and expense when all you need is a toy, some basic tools, and time?

Defense Distributed, maker of the Ghost Gunner CNC mill isn’t worried. When contacted by TTAG, a Ghost Gunner official sarcastically noted:

“I guess we’ll close up shop, and become an airsoft conversion company.”

They apparently prefer marketing to intelligent people who want to build quality gear, rather than those willing to blow their hands off with what amount to improvised plastic grenades.

The Bakersfield Police Department didn’t respond to an inquiry as to how they determined the airsoft gun had been converted for live ammunition. We’ll let you know if we hear from them.

This proves most criminals are not the sharpest crayon in the box. I am pretty sure I can come up with a safer way to make a cheap gun that isn’t likely to blow up the first time I pull the trigger.

Actually I suspect it proves that police departments are not always the most truthful crayons in the box… but who knows, maybe it really can fire 357… once. 🙂

Define fire!

Somehow set off the primer and ignite the powder. You’re on your own after that!

A lot of courts in California require the enforcers/prosecutors demonstrate that the firearm is functional (usually via the ATF, CA DOJ, or local firearms crime lab testing). A nonfunctional firearm usually reduces the severity of a crime/bail, and could even result in some (usually firearm related) charges being dropped….. I would very much like to be a fly on the wall when that trigger is pulled. Barring that I am very interested to see how “functional” this “firearm” actually is in the crime lab report.

Would be more effective to charge him with possession of a destructive device (bomb) than a firearm. Because I think we all know the likely effect if the trigger is pulled on that thing, especially with a .357 mag in here. I might buy it being able to make it through a cylinder of .38 special loaded to about 400fps with 110gr loads.

Maybe. I still wouldn’t be willing to be the one pulling the trigger.

And yet, they enforce unavailable if impossible technologies like microstamping to prevent new models of handguns coming into the State.

This only goes to show that this State favors felons and criminals and have little care for its law abiding citizens as long as taxes are paid.

Finally! The search for a working airsoft grenade is over!

Or melt the barrel with the first round

The Bakersfield cops are playing to a stunningly ignorant audience. They know exactly what they are doing and who they are talking to. Sigh. That includes their elected politician bosses.

Exactly!!

The ignorant playing to the even more ignorant.

Should be able to beat that charge unless they can fire it once. And if they even try they’re going to want to do it remotely.

Bet it won’t fire twice.

I remember seeing a magazine article about homemade guns seized by South African police. To be legally considered a firearm, the gun had to pass test firing by the police. Converted toy guns, or parts of toy guns such as trigger mechanisms, were notable. Plastic toy revolvers (external appearance) converted to fire pistol cartridges by using a steel insert. Single shot obviously.

Also noted were crude single shot shotgun pistols. Air rifles with a barrel extension containing a 12 gauge round. The pellet from the air rifle would strike the primer on the shot shell. More elaborate was the long barreled revolver that would take .303 or .308 cartridges.

Such was the standard of construction, the police noted it was common for there to be the intended victim who was shot, and the unintended victim who either had the gun blow up in their hand or was someone who got hit accidentally

Ian from ‘Forgotten Weapons’ on YT had a good segment (or more than one) about them

If it fires the blast will follow the path of least resistance. That won’t be behind a bullet in a barrel. That’s why firearms are made of steel. (Mostly) Learned that the first time I laid a charge of C-4.

Yeah I was wondering if the guy might have found a way to juryrig a real cylinder in there. If you get that in there and find a way to fire it the cartridge itself should be container enough to fire instead of just exploding. But then the failure would just happen somewhere else unless he basically builds a non-serialized firearm.

Felons can’t own or possess ammo so he’s screwed anyway.

I think all criminals should be gifted one of these upon release.

Here, I’ll paraphrase every ATF statement ever: “Does this scare you soccer moms enough to give us a bigger budget?”

Well 38 spc IS .357.

I suppose, replace the barrel, hammer, cylinder, arbor, trigger, frame, sights, and sure it could fire..

How in the hell would you get the plastic Airsoft hammer to drop hard enough to set off the primer?

Rockets

A big ass rubber band, same as a single shot zip gun…

Load of crap, not believin’ it for a second…

Hey, everyone… take notice here for your next local “gun buyback” where they’re giving you loot or $$$ for turning in a gun.

If everyone can turn in a cheap, $30 toy and get $50 or $100 in cash back, hey, that’s a good ROI.

Oh, I reallllllllly like that!

Now I have to go to my local stores and price all-steel AirSoft and BB guns.

Extra credit: if an all-steel BB gun has a thick enough barrel, you could even drill it out a bit larger to make it look like it actually fires .35 caliber (or something close to that).

Some 1911 framed Airsoft Pistols have been converted to a GSG style 1911 22lr.

Yup….. https://youtu.be/XiHGQR9C27I

I imagine that certain modifications to the gun, such as bore out the 6 shot cylinder and replace with a small diameter hardened steel pipe whose I.D. is about .358 or so and do the same with the gun barrel. Then install a lined hardened steel barrel and install a steel tipped firing pin and replace the smokeless power with black gun power would probably do it, although I sure as hell wouldn’t fire it by hand. Far more trouble than it’s worth.

It really doesn’t matter all that much if the gun was “converted,” as long as it was loaded. Felons can’t possess ammo either. So why spend a bunch of money to prove somewthing that won’t increase the sentence?

Because they aren’t interested in sentencing him – this is entirely for the headline value.

Note that real criminals are almost never actually charged with ‘status’ offenses related to possession of a firearm or ammunition — those are normally just charges that the police write up then the prosecutor throws them away as part of a plea bargain.

Normally the only people who actually get tried and convicted on firearm status offenses are ordinary citizens who got caught without doing anything really wrong. Like the guy in NY who got slammed for using an unregistered gun he had inherited from his father to defend against two armed home invaders, or the “felon in possession” who just got charged after shooting two real criminals attempting to kidnap his son.

These are Malum prohibitum offenses where mens rea isn’t considered an element of the “crime”

80% frames are essentially obsolete in California for anyone who wants to remain within the confines of the law. Now, if you want to build an 80% lower, you first have to buy it from a firearms parts vendor, with a limited background check, get a serial number from the State DOJ and engrave it onto the frame BEFORE starting the build, with a FULL background check, so that the resulting firearm is registered with the state. I am pretty sure there was a bill that required the retroactive registration (including serialization of any unserialized firearm) that was passed, but it isn’t mentioned very much.

No, Mark. The law regarding firearm “precursor parts” along with 80% frames doesn’t take effect until 2024. You can still buy them without any gov’t or FFL involvement and have them shipped directly to your door if you wish.

OK, I just saw that it passed, and I didn’t pay much attention after the required serialization went into effect. No more ghost guns! Theoretically any way. Still a bunch of bunk, but when you have “a ghost gun that can fire a 30 round clip in one second,” what else can you expect from these yahoos.

“…30 magazine clip in half a second.”

● Sen. Kevin de Leon

One more thing Mark, You can not build a 1911 from an 80% frame and then register it. ( don’t ask me how I know) Building a 80% 1911 runs a fowl of the roster law.

Why would anyone build an 80% kit gun and then register it? Doesn’t that defeat the purpose?

OTOH, while you’re technically correct, you can initially build it with one of those goofy “bolt action” slides, take photos for proof, then later convert to standard semi-auto.

I really want to see this thing shoot once or twice.

It’s been known to use Grease Guns that were airsoft to make real ones. That said you basically gut them and put a new set of parts on em.

Realistically you can “convert” anything into a gun by gutting it and building a real gun in the hollowed out space.

I say have the accused squeeze off a hunting round in a controlled environment. No bang, drop the charge. If it goes bang, start at 5 years…… minus 1 for each digit lost. Have him use his strong hand. If he’s left with a bloody stub, he will have learned a lesson and be less of a future threat.

No effing way. Not even with a .22 long rifle.

I don’t know about this,,, I can believe a banger might think this would work, cause their only rowing with one ore in the water,,, but a lot of back pressure in a firearm ,,, I don’t think a air soft gun could hold together… maybe I’m wrong but I’d want the banger to shoot it first to prove me wrong…especially a 357mag.

Even if you replace the cylinder with a steel one and a steel barrel liner. it’s still a plastic frame holding it all together. And not like firearm-grade plastic. ABS plastic.

No way in hell would that thing survive even a single shot. It’s enough of a “firearm” to get you in legal trouble. But far from an actual, even semi-functional one.

Remember when the ATF seized a shipment of airsoft gas blowback M4s because they claimed they could be converted to fire live ammo? Yea you can still buy them just fine. Plenty of major US based airsoft retailers still selling them. And I can tell you that the ones sold back then and the ones sold now are still exactly the same. No changes were made. All parts exactly the same, other than minor tweaks for durability and reliability. Kinda tells you that whole seizure was a load of crap and the ATF had no leg to stand on. I’ve had several shipped to me from various sites in HK and China (they generally have better selection than the US sites) If they were really a problem, I’m sure I would have gotten a visit from ATF by now.

Now vice-versa converting a real gun to airsoft is quite doable. I’m working on a Type 3 AK built on a Tortort 80% receiver and Bulgy parts kit. And an AR with a DelTon upper and 80% lower.

You do generally have to start from an 80% receiver though. The airsoft manufacturers aren’t dumb. While most of the external dimensions are exact to the real gun. Typically FCG pin hole locations and the size of the cavity in the AR lower are slightly different. Different enough to not work with real FCG parts, but close enough that if you tried to re-drill the holes, they would overlap and you would just end up with a paperweight that no longer functions as either a real or airsoft gun. Since the 80% doesn’t have those features milled out, you have a nice clean lower to mill out to whichever spec you want.

If the ATF wants to prove something is a firearm, they should have to test fire it. Only seems fair.

Bet my old Fanner 50 cap gun with “shootin shells” and stickum caps (Mattel mid-late 50s) that I carried in my “Wild West” scenarios in the late 50s early 60s could have easily been converted to fire a live round of some kind more than once (actually ejected a plastic projectile when fired)… Most realistic toy gun ever… now most collectible…

Bullshit.

Anything can be fired once. The tricky part is the second shot

No, the tricky part is surviving with enough fingers and life to fire the second shot.

Well, in an age when just pointing your finger like a gun can get you charged with a crime…..!

Actually, the Japanese Yakuza has in the past had hired out underground gunsmiths to converted some of the super high end and costly airsoft models that were made with metal bodies. Supposedly, the real ammo conversions had worked. The only question for how long before they self destruct.

If I were the defense attorney, I would demand that the Bakersfield Police Department demonstrate that the alleged firearm was actually functional.

Any volunteers?

I want some of that double live ammo. It must be awesome stuff.

Obsolete? Hell no. I’m in the process of making a couple more ARs as we speak. Really wish I had the $$$ to upgrade from my GG2 to the new GG3. I would love to have the extra capabilities that it has.

Boy that 30 round clip must make the Garand really funny looking,

Headline is click-bait trash.

Someone has probably already said it but I want to know where I can live rounds of live ammunition. I mean they’re cops right, so they must know what they are talking about.

This is government (the police) lying to the public. The “gun community” in california should demand a test firing of the “firearm” with 2A people overseeing the tests. CalGuns should be throwing a BS flag on the crap.

It’s not just about Legislation. It’s about when any part of government tries to harm civil rights.

Nope. I’m a serious airsoft player (also with roughly 5 grand in real steel guns so no, one isn’t a substitute for the other) and there’s simply no way. Even if you were to load live ammo into an airsoft revolver (which probably wouldn’t fit anyway) the firing mechanism is COMPLETELY different. Also, most airsoft revolvers use mock, reusable shells with a hollow tip designed to hold a single BB. Given the obvious brilliance of these cops it’s entitely possible those supposed .357 rounds are really just metal mock bullets that act as the feeding mechanism for the toy. The whole in the back (to allow air to pass through and expel the BB) would be a dead giveaway

I just posted the same hypothesis about mock shells. Fearmongering like that through lies is not beneath California.

It’s total BS. A plastic revolver frame from an air soft cannot withstand the pressures from a 357. It’s total BS.

I would not be surprised if there were no modifications to the gun and it was actually an airsoft or regular BB gun that is designed for “shells” that hold the airsoft pellets/BBs.

sounds like a bullshit claim to justify harsher charges against the accused. the accused ought to say, “ok then, go fire it and PROVE it is actually a working .357 magnum firearm!”

Comments are closed.