With the welcome deluge of new gun owners, and especially the new rifle shooters, TTAG has been getting a lot of great questions. Some reoccurring themes include queries about the effects of barrel length and the twist rate of rifling.

Rifling a barrel is a pretty simple idea, and it’s been around for a long time, at least 500 years. The concept is simple, form a helical pattern in the barrel that’s slightly smaller than the projectile to be passed through it, and that twisting pattern will make the bullet spin in flight.

That spin is pretty important, as it greatly aids in gyroscopic stability. If you’d like to fully understand this concept, grab a basic physics book, or do an internet search for the terms “gyroscopic stability” and “conservation of angular momentum“. Those resources will explain to you something you likely already know though your own life experience: objects spinning tend to travel more in a straight line and seem to be less affected by outside forces.

Actually, making the rifling in a gun barrel can be done in a few ways. The most common is “button” rifling, where a roundish “button” with edges cut for grooves is pushed or pulled through a barrel to create the necessary pattern. There’s also “cut” rifling, which is the oldest method and is still the most often preferred by the best barrel makers in the world. It can also be done a few different ways, but the general notion is that a bit is passed through the barrel to scrape away bits of metal until the required pattern of lands is created.

There’s also hammer forging, where a barrel is hammered around a mandrel to create the helical pattern. Hammer forging is not common for high-end custom rifle barrels, but very common in pistol barrels and other mass-produced guns. They work just fine for this application.

That pattern of ridges and valleys (lands and grooves) created by rifling (the verb) the barrel is pretty important, and application-specific. There are many different shapes these lands can take, and different numbers of them. That matters some, and matters more and more depending on how specialized the application is. If you’d like to go down the rabbit hole on land shapes and patterns, know that it is a deep one, with many branches.

The most obviously important thing about the helical pattern inside that bore of a barrel is how tightly it twists. Called “twist rate,” it’s effectively how many times the rifling completes a full 360° revolution in a given length of barrel and, therefore, how quickly it spins the bullet (bullet RPM is a function of its velocity and the barrel’s twist rate).

Twist rates in the U.S. are measured as how many inches of barrel are required for the rifling to make one full rotation and are expressed as one turn per X inches of barrel. For instance, rifling that spins the bullet one full rotation per seven inches of rifling is a 1:7 twist. Likewise, 1:12 is one rotation per 12 inches, etc.

Yes, this means that a 6-inch barrel with 1:12 rifling will only spin the bullet a half rotation before it exits the muzzle. That’s okay. There’s absolutely zero requirement that a projectile complete any minimum or maximum number of spins while inside the barrel.

The vast majority of folks don’t know the twist rate of their firearm, and for the kind of shooting they do, they don’t need to. If you’re shooting your AR-15 at 100 yards at a 6-inch target, or you hunt within a couple of hundred yards with a .264 to .45 caliber rifle, you can just buy any commercially available ammunition advertised for hunting applications and you’ll be good to go.

If you’d like to be a bit more precise than that, or you have some specific applications in mind, then the twist rate of your barrel and the shape of your bullet are going to become much more important.

Quite simply, a longer, more needle-shaped object is harder to stabilize than a shorter, more ball-shaped object.

For my fellow flintlock and traditional cap and ball rifle shooters out there, this is particularly important, and has been well understood for almost two hundred years. My 18th century flinter has a 1:60 twist. For an approximately .50 caliber round ball, that works just fine. It will drill a 6″ circle at 100 yards all day with a wide range of powder loads.

But load that up with a longer conical bullet and the group size will quadruple. It doesn’t take much spin to help stabilize a round ball, but elongate the projectile at all, and you’ll need to double that rate of twist, or more.

For the modern shooter, there are some circumstances where knowing and understanding your twist rate is vital.

First, and most common, are those concerned with precision at longer ranges. The first iteration of the FN SCAR 20S has a 1:12 twist rate. For the bullets it was designed to shoot — the 168gr and 175gr Sierra Match King — that will stabilize the bullet just fine.

But there are other bullet shapes, like the 178gr Hornady ELD, that won’t spin fast enough to stabilize with that same twist rate under all atmospheric conditions. If you’re shooting very small targets, or just shooting from far away, that will make a big difference in how predictable the flight path of that bullet will be.

Folks shooting very heavy subsonic rifle projectiles — like the subsonic loads for the .300 Blackout — need to get a fast twist to stabilize those long bullets, but they may have an additional reason to get the rotation even faster than is required for stable flight. Some companies make copper rounds designed specifically to open up at subsonic velocities. These companies, like Discrete Ballistics, suggest that an extremely fast twist rate, like 1:5, helps to allow the projectile to fully open and then cut through tissue like a propeller.

So if a faster twist rate helps to stabilize a bullet, why aren’t all barrels made with the fastest twist rate possible? Well, for a few reasons.

The faster the twist rate the more resistance on the bullet. That just makes sense; as the bore is more perpendicular to the lands, there’s more resistance as the bullet travels the length of the barrel. This slows the bullet down a little, which has a slight negative effect not only on energy delivered, but predictability at long range. It also leads to slightly increased recoil and a slightly shorter barrel life. But again, only slightly.

There is also the possibility of bullets literally flying apart in flight. This is only a concern with fast spin rates on light, thin jacketed rounds moving extremely fast, like we see with the .22-250 Remington and other similar varmint calibers using varmint bullets.

A twist that is too fast may also have a negative effect on long-term precision as well, although not as much as too slow a twist. The long-held belief is that if a bullet is spinning too fast, then the bullet’s nose won’t tip down after the apex of its curve on the way to the target. This nose-up attitude creates increased drag.

This is technically true, but the amount of additional drag on a small arms bullet is so minute that even in the realm of precision shooting, where the tiniest variables count, this one really doesn’t.

The real issue is that a faster twist rate causes an increased dispersion. In this case, we can think of dispersion as group size. Bullets are imperfect things. As they aren’t truly perfectly balanced around their axis, the faster it twists, the more dispersion (bigger group size) will result.

This is predictable. Simply, if either the imbalance in the bullet is doubled, or the twist rate is doubled, then the dispersion doubles. A more complete explanation of this phenomenon can be found here, provided by Lija.

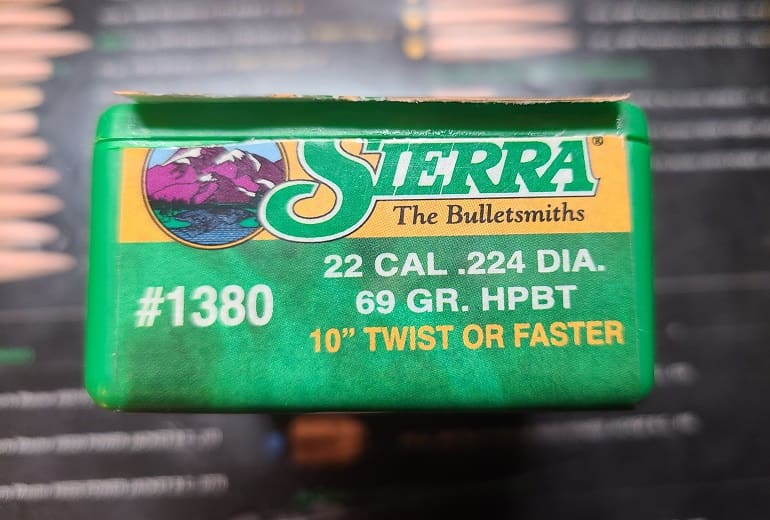

So twist rate matters, but what twist should you use? Fortunately, most of the time we can find that information pretty simply, by looking at the specifications of the rifle and the suggested twist rate that most bullet manufacturers publish. That doesn’t always work, and the more specific you get in your application, the less likely it is to work.

For instance, I needed to know if my preferred home cast lead 405 grain .459″ bullet would stabilize in the new Marlin 1895CB with it’s 1:20 twist rate. For that, I needed to use Greenhill’s Formula or the Miller Stability Rule. For this, you can do the math or just go to the JBM Ballistics free online calculator.

Some of you have noticed that some of the twist rates on some guns are slower than the barrel length. That 1:60 twist on my flinter? Well I don’t have a five foot long barrel. That’s especially true for pistol calibers, where the twist rate almost always means that the bullet doesn’t make a full rotation before leaving the barrel.

Remember your simple physics. An object in motion tends to stay in motion until acted upon by an outside force. Once that bullet starts spinning, it spins at that rate until something (like air) slows it down or stops it. That’s why a longer barrel doesn’t necessarily stabilize the bullet any better than a short one.

However, a longer barrel — to a point — results in a faster traveling bullet. That can lead to increased precision at long ranges, and definitely leads to increased energy delivered to the target.

The point at which barrel length increases the speed of the bullet depends on many factors. Bullet weight, diameter, composition, shape, powder burn rate, land geometry, twist rate, barrel material, and more. The conversion of the solid powder to hot gas propels a bullet with enough force that it overcomes the resistance provided by contact with the lands, but not forever.

For some cartridges, that force is enough to keep the bullet accelerating to beyond 30″ of barrel length. Some others, like the 500 S&W Magnum round fired from a Big Horn Armory Model 89, those bullets will slow after just 18″ of travel. Most .45ACP loads slow after 16″, but most .45 Colt loads are still gaining speed past 20″, as are most .223 Remington and 5.56NATO loads.

If there’s a way to comprehensively predict this point-of-no-return in velocity for any particular barrel and load, I don’t know it.

For most new shooters, it’s best to stick to the basics and start with the bullet. Decide what you want the bullet to do, decide on a bullet, and then decide on a firearm that fires that bullet, based on information provided by the ammunition and firearm manufacturers.

Barrel twist rate and length may be part of your decision-making process, but probably not in the beginning. Eventually it will, and the more specific your needs, the more carefully you’ll need to consider the twist rate and length of your barrel.

So if we are in Australia do we want a right hand twist or left hand twist? Which twist works best in the American hemisphere?

If you’re in Australia twist rate is irrelevant.

“If you’re in Australia twist rate is irrelevant.”

Only on Tuesday, after dark…

A martini with a lemon twist……………

Nope, “Fizzbin”…

Peppermint twist….

“Peppermint Twist”

No, “Fizzbin” :

Phil

As I’ve mentioned here before Australian gun laws are almost as bad as California but we are not gun free.

Right hand twist is generally better in the Southern Hemisphere and right in the north

Here in the southern states, we prefer the rebel twist.

Up north they prefer the henweigh twist

If you fire a bullet across the equator, the spin will reverse and the bullet will start flying backwards, killing the shooter. All true.

Dan, this is really getting frustrating. This is already the third time this week I’ve seen my comment posted, and come back later to the page to find it gone. And I know I don’t ever violate any site policies with what I say.

Is the site crawling with gremlins, or is an admin/moderator removing stuff again?

Hey, where’s Hail?

He should be redirecting that question to me, so I can reply with IP addresses and such.

Hey butt monkey, dance for your bloombucks, I command you!

Trump/Pence 2020

When he does chime in, ask him what he has as an alibi during TTAG’s “disappearing comments” scandal last year in mid-2019. The one that got so bad, people were blocked from the site and Dan had to intervene.

How does Captain America adapt!?

In Australia you want to be shooting toward the east instead of the west.

Or maybe it’s north instead of south?

I don’t know which direction I would shoot in. But I’d have a firm hold on something if I was there. They’re upside down and liable to fall off the planet if they don’t hold on.

How do they keep the water in the toilets?

shooting in the direction of democrat politicians is best IMO.

I read it and now i have a massive headache. Oh i wont need a firearm Joe Biden ( big guy ) is coming to the rescue and i just have to give him half my salary

hope more people understand what you are saying. Fake news isn’t spreading it.

Half?

Some areas are over 60%.

Trump/Pence 2020…..because slowjoe is a crook!

The computer hours at the group home must be later on Tuesdays.

Trump/Pence 2020…and beyond!

Enjoy the TDS shape shifting troll.

Trump/Pence 2020

Good article…The ARs we own have Criterion 18 and 20 inch chrome lined hybrid contour barrels with a 1-8 twist Wylde chamber. Criterion is our go to for barrels.

But but but chrome don’t get ya home………….LOL

Depending on where you live, most hunting shots are less than 200 yards. Almost all modern medium hunting cartridges are capable of good accuracy at these ranges. Face reality, I won’t be shooting across valleys, that’s just unethical. Any 30.06, 308, etc, will be accurate. I don’t worry about it much, barrel length and rate of twist didn’t matter to the deer and bear I take either.

What makes you think all rifles are for hunting and hunting by average skilled marksman? Crazy as it sounds, some people actually do other things with rifles than you do.

Wally1, I put a whole paragraph in that article saying just that. But don’t consider shots over 200 yards unethical at all. They may be for you, and if that’s your skill level, good on your for recognizing that and getting the job done with what you have available. But other folks can, and do, regularly hunt much farther than that with just as much, if not more, surety than your 200 yard shots.

The only difference being that they are in no way hunters, but are more shooters. This is not to say that it isn’t perfectly acceptable to be a long-distance shooter at living targets. It is merely to state: do not fool yourself into thinking you are a hunter. The animal has no ethical chance to outwit you with its natural faculties, pronghorn excepted. There is a reason that for most of history, when people had moral and ethical principles, such behavior was considered the work of an assassin and beneath an individual with any sporting sense or courage. To pretend that “those who can, do” is also silly. There are many world-class shots who will not take shots at game at such distances, because they are motivated by respect, not the tiny ego and swinging d*cks of what is often styled the “competitive shooter.”

Couldn’t disagree more.

agree 100%. I don’t even see why people call it “hunting” anymore, it’s not. just a commercialized industry to suck your disposable income, so easy anybody’s grandma or 8-year-old can do it.

or that stupid PC term “harvesting”, why don’t they call it what it is, slaughtering or killing or even murder, some hunters call it that, say that is what they are going off to do.

shooting a poor defenseless animal that was minding its own business and now its mate doesn’t know where it went, it never comes back to its children and they die. and for what. someone’s amusement. that’s sick.

if anything should be called hunting, it’s things like the Africans that get in a gang of 20 and take down a lion with spears, or the Japanese that chase down a bear with dogs and kill it with a spear, or boar hunting with a spear. that’s hunting. be a man, for chrissakes.

Gus, I’m with you pal.

Slaughtering trophy animals to prove your ‘abilities’ is just sick ego gratification.

I have no problem with using a firearm and lethal force to protect one from another’s aggressive attack.

I have no problem with hunting for food, tracking the game, skinning and processing is a valid use of a firearm… If you’re hungry.

But slaying a living creature just for the trophy is not honorable.

I have found I have much more fun crawling into a thicket by a deer Trail long before sun up, waiting for the animals to go to water before dawn and smacking them on the rump and counting coup.

I already know how to kill, it’s much more important to learn how to live and let others live.

Gus. You cannot murder an animal.

When Man eliminated the natural predators and wild areas animals inhabited a situation was created that only hunting can correct or we can rely on cars, starvation, and messy interactions with dangerous animals and humans to take it’s course. Personally i consider myself tasked with doing a job that needs to be done. If you’re disturbed by the practice of hunting, especially when the game is eaten, then think about what happens when deer or bears overpopulate close to towns.

you don’t have to tell me. you can tell the ones who say they are going off to commit a murder, or brag about the ‘murder’ last week, or show you pictures of “the murder scene”. haven’t you ever heard such talk?

No, gus, I haven’t. Maybe you should hang around a different group of people.

It is still impossible to murder an animal.

I didn’t expect such an adverse reaction. You are correct that some hunters can make ethical kills in excess of 200 yards, but face facts, most Hunters practice once a year just before season opens.

Competition shooters/marksman are to admired, perfecting a science. The rest of us hobbyists, not so much.

Shooters? Hunters? Is distance of the shot the measure of the difference?

What about food on the table?

What about not being able to put food on the table?

Unethical? lol wtf?

Only if they have the proper equipment………..

“If there’s a way to comprehensively predict this point-of-no-return in velocity for any particular barrel and load, I don’t know it.”

That is unfortunate as it is a question I have asked myself and been unable to answer and, unfortunately, don’t have the resources to do the extensive testing that would be necessary to find said answer empirically. Essentially, I have asked the question, “What is the optimal barrel length for *insert load data and twist rate here*”, or, “What is the optimal load for, *insert barrel length and twist rate here”, and so on. Really, my interest in this arose from looking at pistol caliber carbine designs and wondering what exactly is ideal in terms of barrel length for a given load or group of loads. I’ve seen much lore on the topic – Someone claims that 18″ is optimal for some .357 load, someone else says 16, someone else says 20, omeone else is certain that 22″ is ideal for .45 colt, someone else says 20″ for .44 magnum etc., etc., ad nauseam. I recognize, of course, that there is not a simple solution space given the available variables but, It is the kind of thing I would like to be able to calculate. It would be very handy for working up loads for uncommon combinations of round and barrel length. When time allows, I’m sure I’ll poke around a bit more but, I must admit that I am surprised that there is not some tried and true computational method to get into the ballpark.

There is no magic formula; you need to test your load in various barrels and see the result. I would recommend that you go to http://www.ballisticsbytheinch.com/ and see the various handgun loads in test barrels chopped down inch by inch. For example, most but not all 9mm loads seem to max out at 17″, with an 18″ barrels yielding slightly lower velocity.

Then there’s the possibility of working up a load for your barrel. Black powder shooters lay a white sheet on the ground and fire above it, searching for unburnt powder grains as they work the load up for a particular bullet. Or you could use a chronograph. I suppose the unburnt powder search could also work for smokeless; check the videos of guys who experiment with making loads with range sweepings!

Fred, I’m a pretty avid flintlock shooter. I also enjoy shooting BP military cartridge matches, and participate in the occasional Cast Bullet Society match. I used to be all about the Rendezvous matches, and won a few. The kids really loved them.

The white sheet in front of your bore is a better indicator that you have a poorly sealing bullet than too much powder. Depending on the powder type, it is common to leave 1/3 of the total charge unburt in the bore. That powder would be unburned, but not show on the white sheet. The best way to see if you have a lot of unburned powder is to just swab the bore and take a look. The right bullet and patch are everything. If you get those right, you’ll get great velocity, low SD, and have to use very little lubricant to get the job done.

I experimented with different powders, testing muzzle velocity in a 9mm pistol vs. a 9mm Hi-Point carbine. I did the same with .357 Magnum, 5″ revolver vs. Henry rifle.

The longer barrel resulted in increased muzzle velocity with all powders I tested, but the magnitude of the increase differed significantly, depending on the powder I used. Not surprisingly, slower burning powders produced a more significant increase in muzzle velocity with the carbine barrels.

All that is to say that the optimal barrel length depends on the powder, and/or the optimal powder depends on the barrel length.

MyName,

You and I have asked fundamentally different questions. You are asking for “optimal”, and that’s fairly subjective and depend on your particular criteria. I’m asking “at what length does the muzzle velocity begin to decrease”. That’s something where there are just too many variables to simply calculate. Things like, how many rounds have gone down the barrel in total, and what type of rifling is the barrel, would make enough of an impact to change the results.

MyName, you’re talking about 2 different things. longest barrel length is one thing, but when you’re talking about twist rate, that depends on how fast you are going to shoot your bullet. if you take the same bullet, say a .357 125 grain, load it light so it goes slow, and shoot it out of a handgun so it leaves the barrel slow, you are going to need a faster twist to make up for it. now load it hot, and shoot it out of a rifle, it goes way faster, so you need a slower twist otherwise it spins too fast.

and there are all sorts of bullet weights, powder loadings and barrel lengths resulting in a wide range of speed that the bullet leaves the muzzle, so there are all sorts of twist rates to choose from.

“If there’s a way to comprehensively predict this point-of-no-return in velocity for any particular barrel and load, I don’t know it.”

I wrote a somewhat long post expressing my interest in finding a computational way to address this question but, for some reason, it went to moderation and disappeared.

Anyway, other than a boatload of empirical testing with various barrels and loads, does anyone know how one closes in on a ballpark estimate of what the optimal barrel length and twist rate is for a given load or, vice versa?

QuickLoad and the Berger bullet stability calculator are ways to get those ballpark estimates fairly easily. If John doesn’t use it though, I image there is a good reason, though.

I’ve not used QuickLoad, looks interesting, but, even if it is great, I am more interested in learning what I need to write my own ballistic calculator more than I am interested in using one someone else wrote.

It is primarily an internal ballistics calculator/simulator. I’d guess the main equations used are thermodynamic ones predicting the burning of powder in a partly confined space that increases in volume. It uses 7 powder properties for the calculations. QL is one German guy, Hartmut G. Brömel. I am not sure when he first released it but he has been working on it for decades. Even if you are a chemistry, physics, and programming genius (which I am not saying you aren’t) I imagine creating a similar app would be a huge amount of work. He has the properties of hundreds of powders and the dimensions of thousands of cases already there.

Of course, QL is frequently quite a ways off. With N110 and compressed loads in a .357 cartridge it says the max loads recommended by Vihtavuori are way overpressure but upon trying them one finds the VVs empirical data was, of course much, better. However, I find that about 2/3 of the time QL is pretty close to what I get when if test a load. It is certainly not reliable enough to use it max loads it says should be safe without working your way up to them though. It is an very imperfect tool but I find that it does save me time in working up loads and figuring out roughly what should and shouldn’t be possible. I also shows what it’s guesstimate for the pressure at any point in the barrel are and what the bullet velocity is there.

Quickload is a valuable starting point for load development, but nothing more. You can’t put in enough variables to answer the question at hand.

The Berger stability calculator uses the Miller Stability Rule linked in the article. I use it regularly.

The optimal barrel length will change, in addition to the factors in the article, bullet weight, bullet shape, and powder burn rate. One simple thing to remember is that shorter barrels require faster burning powders, and longer barrels slower powders to get optimal results. After that it is all down to experimentation within the published power limits. In addition to too much powder/too heavy a bullet causing a caboom, there is the other factor that more power and higher velocity is not always better. A classic example are black powder pistols. Although the modern iterations in .36 cal can hold 25 grains (by volume) of black powder or substitute, best accuracy is 18 to 20 grains. Similarly, a .44 cal best accuracy is 27 to 30 grains, although the chamber can hold 40 or even more. In .45 colt, case capacity for the original black powder cartridges was 40 grains, but most loads were only 30 to 35 grains.

These same factors exist for smokeless. A reloading guide will give you powder weight ranges for different powders, different bullet shapes, and different bullet weights.

yep. it’s well known among target shooters that hot loads suffer in accuracy, and all their super-accurate factory loads are sort of weak.

I think it’s caused by higher gas pressure, as the bullet leaves the muzzle, pushing on the heel of the bullet and destabilizing it a little.

that would be one case for using a long barrel if you want high velocity. the gas pressure has dropped at the muzzle and you don’t get the destabilization.

Why would you need to impinge a 1-60 twist on a spherical ball? Where’s the aerodynamic advantage? Won’t any kind of appreciable spin make it progressively ‘yaw’ off-axis like a curveball in baseball when fired?

Not when the twist is perpendicular to the flight path. To my knowledge, baseball pitchers cannot impart a substantial amount of spin on a pitch on a perpendicular axis. But, a round bullet without spin is essentially a knuckleball, and will behave with similar unpredictability.

Allegedly the round ball is flattened into a cylinder as it enters the barrel so rotation would help. JWT might elaborate .

I also have wondered about the aerodynamic advantage of spinning a sphere.

Let’s not mix the angular momentum/gyroscopic stabilization and aerodynamics. Spinning bullet is stabilized even in vacuum.

This.

I would encourage you all asking this question to do a couple of things. First, go read up on those two links provided about gyroscopic stability and the conservation of angular momentum.

Then, think about what you’ve seen in the real world. A top spinning. A bicycle wheel turning. Both are cross sections of a sphere.

Is there an axis to a ball that is not spinning? Do you create one by turning it?

We have all witnessed gyroscopic stability. Some of us can spin a basketball on our fingertip (there’s a sphere for ya). The spinning top will move across the table in a seemingly random pattern. The bicycle wheel will move down the road. Gyroscopic stability keeps the axis of rotation oriented in the same direction but doesn’t prevent the whole object from moving in any direction.

So… back to the spinning, spherical bullet with its axis of rotation aligned with its direction of travel as it leaves the barrel. Whatever forces change that direction (gravity, wind) could seemingly act on a spinning sphere the same way they act on a non-spinning sphere, changing its direction of travel without changing the axis of rotation.

There is something else going on with that spinning sphere that I’m not comprehending.

I gave up doing the twist when I turned 60, I only slow dance now.

To combine the previous mention of Australia with this post, “Waltzing Mathilda” isn’t actually a waltz, but I don’t think anyone twists to it either.

LoL. Something Chubby Checker could elaborate on, but JWT did a good job.

I recently learned that twist rate is also sometimes measured as a ratio of full revolutions vs barrel diameter. It’s a little more complicated to measure, but has the advantage of being unitless, kinda weird talking about 1:9-inch twist on a 5.56mm barrel. It also helps helps in comparing what is fast or slow for various cartridges. You’ll find a 1:9 .223 rem and a 1:20 .45-70 aren’t that far apart with a twist rate (L/D) of about 40.4 vs 43.5.

it depends on what you’re doing with the numbers. an engineer calculating stuff about the barrel, might find twist ratio more convenient. a farmer only needs to know twist rate.

same as naval guns described as diameter and multiples of that in length, like a 16/50 is 16″ bore and 50 times as long. why do they do it that way? hell if I know but they have their reasons.

if it was me I would still call it a 16.00 caliber with a 67 foot long barrel. sounds a lot more cool, doesn’t it? that’s why they should put me in charge of the Navy, because they have ding dongs that call it a 16/50.

And then there are certain bullet designs that break the “rules”, one example would be the .224 Noslet 64gr Bonded Solid Base PPT, designed specifically for the 1:14 twist, and they are phenomenal in the .22-250…

Unless I’m trying to wring out every bit of a bullet, I’ll take a flat based bullet any day. I don’t understand why, (and someone here can probably explain why) but I have a much easier time building accurate rounds with a flat based bullet.

I experimented with this for a while when I was silhouette shooting. For instance I had to hunt for the right recipe for the Speer .284″ 145gr BTSP bullet, but it was hard to get the Speer .284″ 145gr Hot Cor (solid base) bullet to print a bad group. I’ve heard the same thing from varminters, but I’ve never had a good explanation of why this occurs.

probably because the gas pushes on the base of the bullet more evenly when it leaves the muzzle, and, there’s no curved surface to push it sideways. remember that boat tail on a bullet is for in-flight aerodynamics and transition of the sonic boundary.

I have the same experience with flat base bullets. I spent the better part of a year working on handloads for a Remington 700 in .22-250 and a 10″ T/C Contender in .223. The plain old Hornady 55 gr Soft Point gives me .6 moa in the rifle, and Speer 50 gr HP TNT does 1 moa in the Contender. Both guns are off the shelf, and those flat base bullets outshoot all the fancy ones I tried then and since.

I was really excited when Nosler released these, and jumped on the opportunity to try and develop a .22-250 load with them…loaded over Varget(my go to), they have been phenomenal, and all I ever shoot from my .22-250 anymore, sans some 55gr PPU…

Tika T3X hunter in .308win with a 1 in 11 twist

Has best accuracy with 168gr. ammo

As the bullet weights get lower or higher, the groups open up. Not that it won’t shoot anything else. Its more that 168gr is what it likes.

From what I’ve seen and read, most Beretta 92’s (being considered duty guns) like 124gr. 9mm. Not that 115gr won’t shoot or even produce accuracy.

This is something I feel truly needs to be put out there. The fact that it likes that weight IS a function of the twist, barrel length, etc. You can do the math but thats like zeroing a scope by eye balling. That can get you close but the only way to know is still ultimately to spend time shooting it. Different ammo manufacturers will often produce varied results. Some of these guns are simply meant for short range and others are designed for hitting targets over 1000 yards away. Its why self defense shot guns are generally between 18 and 20 inches long while one at 26+ inches gets used for clay targets and bird hunting.

it’s only my guess, but I would say that 168 grain in a 1/11 twist isn’t so much that the gun likes it, as I would say that’s evidence that the 168 grain profile is finicky and doesn’t do as well with other twist rates. (length and profile/ogive have an effect)

following that hypothesis, you might see other bullet profiles more easily stabilized when using the wrong twist.

I’ll go with that. It makes sense.

My S&W Sport has a 1 in 9 twist which is OK for my purposes. I’ve only shot 55 & 62 grain boo-lits in it. And none since the ammo famine…but who know’s after November 3!

Stuffs gonna be bad no matter who wins. If trump takes it you can probably expect some uhhh…”peaceful protests”

Yup, trash compared to what an AR can be but good enough to larp with the most common ammo.

My Bushmaster is 1:9 twist and I shoot mainly 55 grain but also shoot up to 85. No accuracy issues out to 100 yards. If I’m planning on going farther out it’s 308 time.

I see that the marketing folks at Discrete Ballistics have been smoking the same crap as the gun grabbers who banned the infamous Black Talon bullets. Even with a twist rate of 1 in 5 inches (or a bit under one Radian per inch), their bullet isn’t going to make more than a few revolutions during is transit through a human carcass. With a rotation rate of about 15,000 radians per second and a radius of about five millimeters, the centrifugal force that might encourage the bullet to expand is inconsequential compared to the hydrodynamic forces the bullet experiences as it transits water based tissues at over 1,000 feet per second.

My deepest respects for the guy who wrote the program to model the internal Ballistics of firearms. Just calculating propellent burn rates requires second order differential equations which can not be solved analytically. Only folks who have a grasp of internal ballistics will understand why you can fire a .50 BMG cartridge from a 12 gauge shotgun without looking yourself. (Hint, blank firing adaptor) Makes a great conversation starter at Fourth of July parties.

the centrifugal force is not insubstantial.

me and a friend were shooting at watermelons with his 357. it was really sloppy. the cylinder must have been misaligned and shaving the jacket off one side. we were no more than 20 feet away, couldn’t have missed, but the bullets weren’t reaching the melons. not one hit. they were exploding.

I don’t remember what model he had, but average twist rate on a .357 Magnum is around 1-18″ and with a barrel length of 4″, they were probably doing 1400 ft/s.

and this is how you calculate RPM’s.

1400 feet/sec = 16,800 inches/sec

divided by 18″ = 933 rev’s/sec

times 60 seconds per minute

= 56,000 RPM

so the bullets with jacket partially shaved off, at 56,000 RPM, was enough to make them explode sometime after the muzzle and before 20 feet.

you might say of course, the jacket was shaved off, that’s why they blew up and centrifugal force doesn’t amount to much.

but that’s exactly the point. it’s enough to blow up a shaved FMJ into lead dust that doesn’t even hit a watermelon at 20 feet. that’s a lot.

Was coming here to add to this:

RPM is a combination of muzzle velocity and twist rate. In most cases, when you go with a shorter barrel, you lose muzzle velocity, and thus lose RPM as a result unless you increase the twist rate accordingly.

Find out the nominal RPM for your bullet, and calculate accordingly.

Great reading TTAG. Good article. Well written and easily read by pro to beginner!

Much appreciated.

Do shottys next 😎

There are two articles I’ve been working on for the better part of this year, just because of the research involved.

“Affordable” double barrel shotguns, and their role in America, are one of them.

I’m of the opinion that the shotgun in the hands of homesteaders is the gun that won the wild west.

Backed up by the trap door springfield used by the soldiers on the frontier.

There’s surprisingly little writing on these guns, and there were so many of them, both in number and variety.

Before the internet I read several references in history books about shotguns on the frontier. Even the army issued a number of shotguns to units on the frontier to help with foraging.

Authors commented on having a real good reference in the records of Sears, Roebuck. Their records showed that by a large number they shipped more shotguns to the west than rifles. Followed closely by what we would term concealed carry handguns. Small, fairly cheap pistols that were .22, .32. 38 and .44. Generically termed as ‘Bulldogs”.

The Hollywood image of the tied down SAA and Winchester repeater on every horse was not accurate, it would seem.

This was a really good read. Well done Jon!

Seriously. Thanks JWT. I’ve been deleting most TTAG articles from my inbox that have just been more of the same political tail chasing. It was nice to save this one for later, read it, enjoy it and just skip past the comments attempting to make barrel twist political.

Thank you sir.

This is a good article for people who actually shoot and reload I went through the same thing trying to figure out if I could stabilize a subsonic 300 grain hornady xtp 44 magnum in my suppressed contender.

Overthinking firearms seems to be a hobby for some folks, and good for them. I guess it can be fun if you are one who loves details. But some of the best shots I’ve ever seen picked a gun and load they liked, then practiced with it and got real good with it. All the while developing hunting skills as well, and enjoying occasional target shooting. They had one shot kills on deer and didn’t give a flying fuck how many times the bullet was turning around.

Thank You.

“Barrel twist rate and length may be part of your decision-making process, but probably not in the beginning. Eventually it will, and the more specific your needs, the more carefully you’ll need to consider the twist rate and length of your barrel.”

Interesting stuff but sorry guys, in my case, eventually it won’t. Too much trouble too late in the day. So, I’m going to leave it to the ballistics engineers for my next .308 with its 1:10″ twist. Anyway, my compliments to JWT on a fine article.

I confess, didnt read it all but my 30 yrs of firearm experience (and I must say I learn something everytime I load 50-100rnds of ammo) says yes, twist specs should be able to predict if not dictate what bullet weight will work the best (be most accurate) but mfrs specs are somewhere between fact, fiction , and fantasy. Like a box of chocolates, you never know what you will get from a rifle mfr or what weight bullet will be the most accurate. Custom bbls are another matter all together. I have a $400 entry level 308 factory rifle whose specs say 10 twist which would indicate 175grain bullet or heavier should stabilize and be accurate. Ive ashamedly never measured the twist but 175 grain match ammo will product about an inch group. 168 grain match ammo will produce about a 3/4″ group and 150 grain match ammo will print about a 1/2″ grp. So either the rifle is not a 10 twist or there is something else very weird going on.

A longer barrel/faster bullet DOES NOT improve precision. A longer barrel CAN increase the shooter’s error budget, but that isn’t the same thing as improving precision. All else being equal, a shorter barrel with the identical profile will yield better precision because it is stiffer and so will flex less under the stresses of firing than a longer barrel with the same profile. And lengthening the barrel will increase bullet velocity, which decreases the impact of the shooter’s errors in holdover and windage, but only to the point where the negative effect that the increase in the barrel’s vibrational period counteracts that expanded error budget. But increasing barrel length does absolutely nothing to improve inherent precision.

A longer bullet might require a tighter twist to stabilize but bullets fired at subsonic velocities (or more precisely, sub-transonically) don’t need as tight a twist as the same bullet fired super-transonically. That’s because longitudinal static stability is an arm-wrestling match between a bullet’s Center of Pressure and its Center of Gravity. If you’ve seen the drag chart for a bullet, you no doubt noticed how the drag curve steepens considerably as the bullet crosses the lower critical threshold and enters the lower transonic region. And if a bullet is anywhere in the transonic region (or faster), the extra drag magnifies the power of the Center of Pressure, causing that bullet to require significantly more rotational rigidity, else its overturning moment will be too great, its CP will overpower its CG and the bullet will become unstable.

The upshot is that if you’re setting up a dedicated sub-transonic gun, you can get away with a slacker twist than a one you might also be shooting super-transonic loads in. Important to note for shooters who might want to boost their gun’s sub-transonic terminal performance by offsetting the loss of velocity with extra bullet mass because you can shoot a longer/heaver bullet than you could get away with at traditional rifle velocities and it will remain stable. And for bonus points, a typical spire-point bullet always has better longitudinal static stability if you load it meplat-first into the case and shoot it base-first. That’s because the base is the heavier end and shooting it base-first shortens the CP-CG moment arm, which makes it more difficult for the Center of Pressure to overpower the Center of Gravity. So if it won’t stabilize point-first, try shooting it butt-first instead. Which will probably increase terminal performance in the deal because at velocities too low to cause significant hydrostatic shock, and particularly for bullets that are sub-transonic, a blunt projectile will tend to cause a larger crush wound than a pointy one would.

Overstabilization is only a factor with very large projectiles, like artillery rounds. It is non-existent in small arms rounds.

Nor does tighter twist have a significant effect on bullet velocity (proved in testing by Bryan Litz). Shoot identical cartridges from a 1:12 AR and a 1:7 AR and the difference at most will be single digit FPS. Your chronograph probably has an error rate higher than that, and it’s highly unlikely that the SD of your ammunition is anywhere near that low, so it’s doubtful you could even test for it with any reasonable degree of precision. And if there is extra “resistance” driving a bullet down a barrel with a tighter twist, its effect is not unlike raising the compression in a piston engine. Added resistance causes the powder to burn all the hotter and the extra heat cancels the affect of the extra friction.

Litz also has test data to prove that just because a bullet has “gone to sleep” doesn’t mean it isn’t nutating, however slightly, which has a negative and measurable effect on BC. The upshot is that if it’s a rifle that you intend testing the long-range limits of, or even if you just want to make your bullet perform the best that its BC will allow (=flatter trajectory and less wind drift), you need a barrel twist and bullet combination to yield a stability number (Sg) of at least 1.5.

You have fallen into believing this fallacy exists “All else being equal,”. It does not.

Precision? Or Accuracy? Or both?

https://duckduckgo.com/?q=precision+accuracy&iax=images&iar=images&ia=images

Here’s some news you can use. 1-7 twist barrels only stabilize 75 to 77 grain .223/5.56 projectiles well, period, end of story. If you want the ability to shoot less expensive 55 grain ammo in your AR that groups well at 100 yds you need a 1-8 or preferably a 1-9 twist barrel, period end of story. Not sure why the AR market was flooded and dominated almost exclusively with 1-7 barrels that are incapable of accuracy with the less expensive 55 grain ammunition.

Comments are closed.