Just about a year ago now I was in the back shop at C.a.r. Firearms, just south of Seattle, when a robust, blocky, yet sleek-looking item caught my eye. It consisted of two parts tethered together like makeshift nunchakus, the larger of which was firmly locked in the horizontal position in a stout 4-inch bench vice.

After a second and then third glance, I deduced the supposed tool to be one for the workbench-bound gunsmith, not your average enthusiast making a few repairs here and there. But what exactly was the purpose of this curiously-machined apparatus? I inquired and soon found out there was much more to the implement than first met my eye.

The obvious hardwearing bench tool turned out to be The Device, an AR-15/M16 upper receiver fixture manufactured by The Device Manufacturing. It also happened to be the shop proprietor / gunsmith’s favorite upper receiver fixture, hence it’s mostly-permanent place between the vice’s grips.

The reason for my visit that day was to talk shop about scope mounting and muzzle device timing using a digital protractor. So go figure, when I handed him an Armalite M15 SPR Mod1 upper (7.62×39) for demonstration, we used The Device to properly mount the Leupold VX R-Patrol 1.25-4×20 optic (above).

When I asked why he preferred The Device over other fixtures and tools that index with the barrel’s star chamber, he noted that The Device provided better internal support and retention of the upper. His experience was that tools indexing in the star chamber allow for a greater degree of variance and the differences in chambers can lead to a variety of tolerances.

The Device seemed to work very well that day. It was efficient and firmly locked the upper in place, keeping it from shifting off of our zero during scope mounting. Yet, the gunsmith’s enthusiasm for The Device and his detailed accounts of the tools’ other purpose-built functionalities left me wanting to fully understand The Device and all it offered so I connected with Ken Cashwell, President of The Device Manufacturing, to learn more and arrange for T&E.

Cashwell was extremely welcoming to my request and over the course of several telephone conversations and email exchanges, I came to understand how and why The Device, or the “hunk of aluminum”, as Cashwell sometimes humbly refers to it, came to market.

After working with every available upper receiver fixture – and modifying most in one way or another to better suit his needs and preferences – Cashwell was spurred to create an improved upper receiver fixture for the M16 / M4 / AR-15 family of rifles / carbines / pistols that resolved his points of dissatisfaction with existing models.

The Device’s primary purpose is to serve as a Mil-spec upper receiver fixture, locking an upper receiver in place to assist with assembly, disassembly, maintenance, and/or repair. There are also additional features specifically designed to service the rear sight on A2 variations. Flip The Device over and you have a dimensionally accurate M4 upper receiver rail section for working on optics.

One of the reasons I was drawn to The Device was its unique two-piece design, utilizing a heavy base and surrogate bolt carrier group with changing handle to secure the upper receiver. Cashwell openly credits the M1 Garand bolt assembly-disassembly tool (Fulton Armory reproduction shown above) as the inspiration for his design, which now holds several patents.

The surrogate slides over the “T” spine protruding from the base of The Device and the two pieces are held securely by a ball detent, which creates positive lock-up and prevents the surrogate from sliding out of the upper. This feature allows users to vertically orient The Device at their workstation. And, of course, the design eliminates the need for locking takedown pins, which can easily become misplaced or separated from their counterparts.

Now, since The Device’s lug recesses and surrogate BCG / charging handle are machined to Mil-spec dimensions, The Device can also be used as a gauge to determine if most of an upper is Mil-spec or not. If the upper does not fit into the lug recesses and/or the surrogate does not lock inside the upper, some part of the receiver is not Mil-spec.

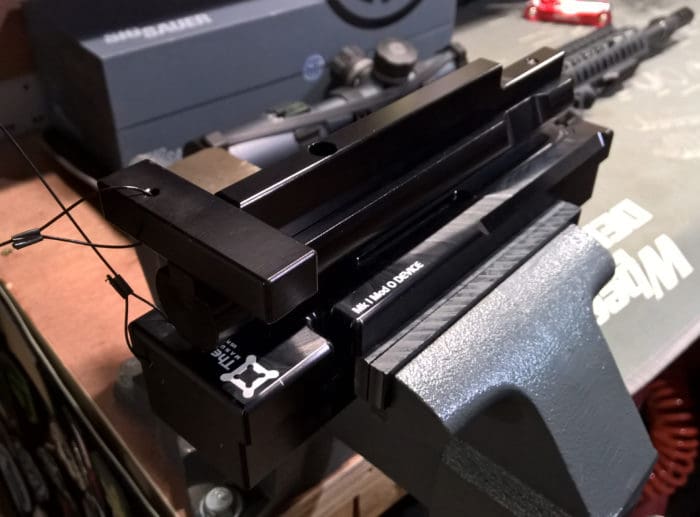

On the bottom side, The Device’s integrated 1913 rail is precisely machined to M4 top receiver rail specifications with each of the thirteen crisply-cut picatinny slots clearly numbered. Again, if your mount does not mate properly with The Device’s M4 rail, there is something wrong with the mount or the mount is incompatible with Picatinny rail systems.

Altogether, both pieces are very well-milled and finished. All non-essential sharp corners are nicely rounded and all surfaces of the 7075 T6 aluminum components are nicely Type III Hard Coat anodized. The two halves of The Device are then secured very well with small-diameter coated wire, crimped together at the ends.

However, when combined, the base and surrogate BCG tip the scales at over 2.5-pounds, which should give you an indication of just how much material is in the “hunk of aluminum”.

The Device Manufacturing’s home page features two videos in which Cashwell walks-through The Device. There is a bit of overlap in content between the two videos and I’ve found the one below to be the most helpful, although it is somewhat lengthy for an overview (~11-minutes).

However, the second video does have some additional information, a few different angles and views of The Device, and more coverage of the M4 rail section on the tool.

Or check out Brownell’s Quick Tip on The Device for the quick and clean summary.

Digging-in a little deeper on our end, there are a number of things to be aware of.

Beginning with The Device’s base, you will notice a number of distinct features, each of which has been designed with a specific purpose.

At the rear of the base, beginning at the top left corner, there is a pass through hole for the coated wire lanyard. In the center of the rear portion sits the takedown lug recess and to the immediate right of the recess is the A2 rear sight elevation spring pass-through hole.

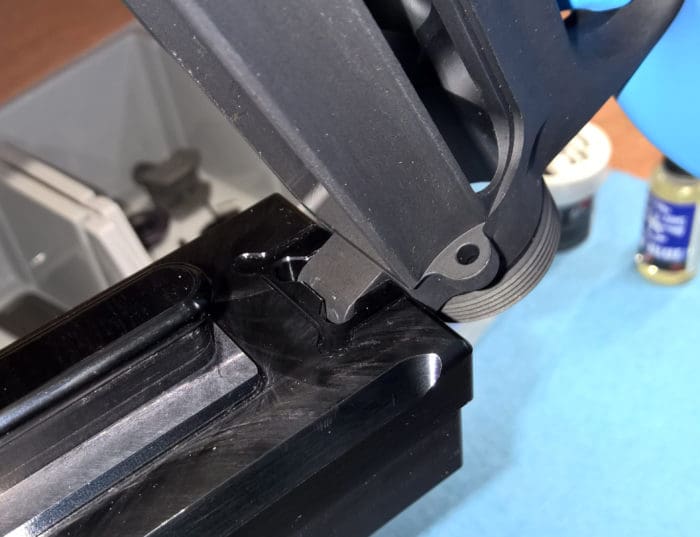

Fading out of frame (above and below) is the spine of The Device with ball detent dimple showing.

The notch in the edge of the base located to the side of the takedown lug recess provides clearance for a forward assist roll pin to be driven out of an upper. More times than not, and especially if you position The Device within the vice’s grips, it will also catch the pin when it comes out.

At the front, the pivot lug recess is cut short, allowing The Device to accommodate a multitude of rail systems. Most fully-assembled Mil-spec uppers should see enough clearance to drop right in (after clearing firearm, separating from lower receiver, and removing BCG and charging handle) when performing routine maintenance or working on rail-mounted accessories.

Finally, the flat beveled edge seen on the long side of The Device in the photo above corresponds to the dust cover on your upper. It allows the dust cover to sit at a helpful angle during installation and also pushes an open dust cover to the side when seating an upper in The Device, keeping it from jabbing down into the fixture.

The upper half of The Device is a bolt carrier group / charging handle surrogate. It fills the inside of upper receiver and indexes across internal flat surfaces to create an integrated internal support structure.

The surrogate is three aluminum sections held together by steel hex-head screws. The main body of the surrogate is comprised of two long pieces – a notched rectangular bar for the charging handle channel and a rounded flat-top bar to simulate a BCG.

The handle on The Device’s surrogate is a simple rectangular bar, positioned perpendicularly across the back notch of the long notched bar. A tether loop is also present in the handle.

A neat feature of The Device’s surrogate BCG is the Mil-spec dust cover recess (above). Not only does the recess allow dust covers to be closed while the upper is secured in the fixture, it doubles as a test gauge for the dust cover.

Simply insert the surrogate fully into the upper (with or without the base), close the dust cover, and pull back on the surrogate’s handle to slide the surrogate rearward. The dust cover should pop open just as if you were charging the firearm and it should be a surprisingly smooth operation.

A quick look underneath the surrogate reveals (from left to right) two hex-head assembly screws and the ball detent within the surrogate’s internal docking channel. The A2 rear sight elevation spring pass-through hole lies just after the channel ends, and the third hex-head screw is located at the end.

A closer view of the ball detent housed within the channel of the surrogate reveals a crisp, corrosion-resistant assembly and smooth mechanism.

Of course, The Device’s base and surrogate BCG / charging handle are designed to work in tandem, with the surrogate sliding over the base’s “T” spine (above) to capture the upper receiver.

When the two inter-locking parts of The Device are mated, the clean and polished pass-through hole for A2 rear sight elevation spring is clearly visible (above).

The Device is also designed so that it does not have any interaction with the barrel. The surrogate stops short of the barrel to avoid damage and also to allow for work across a variety of calibers, like 9mm, .300 AAC Blackout and 6.5 Grendel (for the MKI).

From the front, you can clearly see the surrogate BCG and charging handle mated with the base’s spine, the two ledges that run the length of The Device, and the integrated M4 top rail CNC’d into the bottom of the tool.

The ledges are a terrific feature – until you want to flip The Device over and use the M4 rail. Then, depending on your vice, you may find that the ledges only get in the way, cutting down on needed surface area to clear the base’s “T” spine.

The M4 rail is an interesting feature of The Device and one that sparked debate with nearly all people whom I discussed about The Device with. They theorized as to the value of the rail on the The Device versus the additional cost of machining, which is top-notch and somewhat detailed.

Personally, I found the rail more useful than anticipated. I mounted half a dozen or more optics in the past several months using the rail, many of which traveled with me to the range before being paired with a firearm (or two). And since every upper will have a slightly different fit to The Device, I often relied on the M4 rail for more precise mounting of scopes to rings versus using the fixture side.

However, I probably used the upper receiver fixture just as many times to mount scopes; locking an upper into The Device and mounting the optics directly to the firearm. Even for a gunsmith who mounts a lot of optics, this feature is a toss-up.

As you have no doubt come to realize, Ken Cashwell put a lot of thought into his design for The Device Mk 1 Mod 0. It has very specific features to service the most popular USGI gas operated service rifle variants and it’s built to last multiple generations.

On top of that, The Device is not only built to firmly secure uppers, but also acts as a Mil-spec gauge for upper receivers. If the upper doesn’t fit in the base or the surrogate doesn’t lock into place within the upper, some part of the upper is out of specification.

So with a solid understanding of The Device and its intended purposes, the obvious next step was to get it into a vice and use it as much as possible for as wide of a variety of tasks as possible.

Over the past eight months I’ve used The Device to assist with a variety of upper receivers and scope mounts. Most uppers fit The Device very well, while some billet and “matched” upper receivers, such as 2A Armament’s Balios Lite Gen 1 upper receiver were not copasetic.

Given that The Device is purpose-built with more features to accommodate an A2 upper receiver than any other, I couldn’t think of a better way to fully test The Device’s capabilities than to assemble a USGI A2 upper from Fulton Armory (above).

The Device’s two ledges, which run the length of the tool on both sides, sat atop the vice’s jaw plates, leveling The Device with the vice while keeping it from slipping downwards.

With The Device’s surrogate BCG / charging handle removed from the base, the A2 upper dropped down over the base’s “T” spine and its takedown and pivot lugs dropped snuggly into their respective recess holes.

The design of the lug slots creates a nice, tight fit and its shape doubles as The Device Manufacturing’s logo.

Above, you can see how the front lug recess is purposely cut short to accommodate rail systems. For the purposes of upper receiver assembly, there is no benefit until you begin to build forward of the receiver extension.

Next, the surrogate BCG was inserted into the upper receiver and pushed forward until the ball detent seated into the corresponding dimple in the top of the “T” spine, locking the upper firmly into the fixture. This A2 upper had just a small amount of side-to-side play when secured in The Device.

With the A2 upper secured in The Device, I laid a Mil-spec dust cover up against the supporting bevel and into place on the upper receiver. The angle was comfortable and made holding the spring in place while threading the rod through the cover easy to do with a single finger.

Since the forward assist’s roll pin on my USGI A2 upper was meant to be driven into place from below its housing, The Device provided no assistance for this step.

Could I have left the upper in The Device and driven the roll pin down, thereby making it “easier”? Sure, I suppose. But that’s not how the upper was designed, so the upper came out and the forward assist was pinned into place using a bench block.

However, The Device’s forward assist pin notch worked perfectly, providing plenty of clearance for removing the pin. As you can see in the photo above, if you position the vice’s jaws across the notch it will create a small capture area for the pin.

Installing the A2 rear sight with the upper in The Device was helpful, just like any other upper receiver fixture.

The only difference was that I could have kept the upper in the fixture and used a u-notched pin in conjunction with The Device’s elevation spring pass-through hole to hold the elevation spring up in place while tapping-in the corresponding roll pin from the side.

But I started the installation of the rear sight in the Device and then took the upper out of the fixture and used a block on the bench because I wanted the sight assembly supported. Afterwards I completed the remainder of the installation with the upper in the fixture.

The USGI A2 upper came together as good as I’d hoped it would and The Device supported the assembly throughout the process. Advantages for a single assembly were not greatly significant, but for someone who assembles Mil-spec uppers on an assembly line or even multiple uppers a week, noticeable efficiencies would be realized.

As I mentioned I also used The Device to cross-deck a number of optics. This process entails zeroing-out a level on The Device’s M4 rail, installing the scope rings or mount to the rail, then leveling the scope’s reticle to the rail and locking it into place within the mount.

This can be advantageous when you need to pre-assemble optics and rings because the rifle is not yet available, or if the optics’ host upper was being worked on simultaneously. Or better yet, if you have a biller upper that doesn’t fit The Device’s fixture well. But for the average enthusiast cross-decking is an extra step in the optics mounting process.

After the first several months of use, I took The Device to three mentors, all of which are very reputable local gunsmiths. These are the type of guys who have used, modified, and probably broken, every specialty tool, jig, and bit available. None of them had ever heard of or seen The Device.

After checking out The Device, they all agreed on three things. First, The Device is a well-made upper receiver fixture. It’s sturdy and appears very durable. Second, the M4 rail on the bottom was unappealing. “Why not just stick a scrap section of 1913 rail into a vice and save the extra machining?” was the general feeling. And third, for the money ($329.99 MSRP), they would rather have three or four other gunsmithing tools (not pictured above) that possibly work with more than one caliber and/or can perform more tasks as a combined set.

Their sentiments consistent, experience deep, and toolboxes nearly equal, I couldn’t help but stop and realize that The Device might not even be a perfect fit for many nose-to-the-grindstone gunsmiths. The Device’s best place of employment may just be with manufacturers like Barnes Precision who have assembled thousands of uppers on The Device. Additionally, The Device is also rumored to have been “heavily vetted” in the field on H&K’s 416 platform. Of course, this I cannot personally confirm.

After using The Device upper receiver fixture for the past eight months to assemble and service a variety of uppers and scopes, and conferring with four experienced gunsmiths, several things are for certain. For one, The Device Manufacturing takes great pride in The Device and ensures it is made to exacting Mil-spec standards, allowing it to double as an upper receiver gauge.

And while Cashwell’s design solves quite a few issues prevalent across other upper receiver fixtures, it certainly doesn’t solve them all and is not the be-all and end-all upper receiver fixture. It will be the perfect solution for certain folks, while others will realize more value through a variety of similar tools. Personally, The Device has become more-or-less a permanent fixture in my main vice but I still look to other bench tools for tasks like handguard installation.

Furthermore, The Device is specifically designed to avoid contact with the barrel. There is nothing to hold the barrel captive during muzzle device installation and removal, putting the barrel extension’s indexing pin at risk of damage and the barrel at potential risk of becoming misaligned if the muzzle device is over-torqued. I would not use The Device for muzzle device work.

The integrated M4 rail is a feature that I found convenient for cross-decking optics. However, I and many others are left wondering if the value of the rail section is worth the added cost of machining it into The Device.

The Device Mk 1 Mod 0 by The Device Manufacturing is a hefty (both in weight and price), precise, and extremely reliable aluminum upper receiver fixture for AR-15 / M16 / M4 firearms. It performs its intended tasks exceptionally well, but leaves room for improvement. If you’re assembling large quantities of uppers or working with Mil-spec uppers (especially A2 variations) on a regular basis The Device will surely be a tool you can rely on to help realize new efficiencies for generations.

And if the AR-10 / SR25 platform is your preference, The Device Manufacturing’s MK II variant of The Device is also available. In fact, they invite any and all inquiries for custom order of The Device for just about any weapons platform. Get that wishlist together!

Specifications: The Device AR-15 / M16 Upper Receiver Fixture (MK 1 Mod 0)

Price as reviewed: $329.99 (Available from Brownell’s)

Ratings (out of five stars):

Design: * * * *

The Device’s unique design ditches the traditional two-pin frame of mind and replaces it with a single interlocking surrogate BCG / charging handle / base to secure an upper receiver into a vice. Top-notch machining and the edges are finished very nicely. Several smaller features like the forward assist roll pin notch, dust cover bevel, and A2 rear sight elevation spring pass-through hole come in handy. And while useful, the integrated M4 rail on the bottom of the tool is a feature lost on most folks once they consider the cost. The Device is also specifically designed to support multiple calibers within the M16 / AR-15 platform, which means there is no interface with the star chamber.

Durability: * * * * *

Built to be a generational tool – one passed down within a family or business – The Device is built tough. And let’s face it, there’s not much a block of aluminum can’t handle on the workbench. All parts are finished with a very good Type III Hard Coat anodizing that helps further protect the fixture. The coated wire with crimped ends ties the two pieces together securely.

Functionality: * * * *

Even with a plethora of features and functions, The Device checked-out on all advertised accounts. While not perfect for all uppers such as billet and some “matched set” forgings I couldn’t find a Mil-spec upper that wouldn’t fit correctly in the fixture. However, there is still room for additional functionalities and small improvements.

Overall: * * * *

The Device Manufacturing’s The Device M16 / M4 / AR-15 upper receiver fixture is a hefty tool designed for a demanding environment. It’s only real foes being muzzle devices and billet uppers; the tool makes quick work of upper assembly, repair, and maintenance while also supporting most handguard systems. The integrated M4 rail allows for cross-decking of optical devices. The Device is a well-machined, well-finished, intuitive upper receiver fixture that does everything it is designed to do, yet there is still room to grow and a price tag that could stand to shrink.

For those of you who like to get straight to the point.

“The Device’s primary purpose is to serve as a Mil-spec upper receiver fixture, locking an upper receiver in place to assist with assembly, disassembly, maintenance, and/or repair.”

Seriously… 3,700 words to talk about an upper receiver fixture, with the conclusion being “eh, its pretty good I guess”.

I know, & the author mentioned how the 11 minute video was “somewhat lengthy for an overview”.

I don’t have a problem with an in-depth review, just thought it was funny. I didn’t read it all though. Read down to the video then scrolled down to the price & decided it wasn’t worth my time as I’m not a professional gunsmith. I make due with my Botach Kley-Zion spline tools & Plastix Revolution receiver vise blocks.

Thank you… that’s exactly what I was looking for.

So from what I can tell – you still need a reaction rod or similar for barrel nut and muzzle device (and potentially handguard) torquing? Seems like this device covers just about everything else in terms of the upper.

You’re not a gunsmith.

This gentleman and I are. Gunsmithing is about details. When I’m looking at the work of other gunsmiths and custom gunmakers, I’m looking at details that most gun owners never notice.

I appreciated his level of detail.

Something I’ll never buy (lack of need/use), but love reading about anyway (especially as a manufacturing nerd).

Great article.

Wow! I’ve never seen so many pictures in one article! The only thing missing were the blueprints. Outrageous overkill?

A vise is a clamp (which holds The Device). A vice is a moral problem.

One person’s vice is another’s hobby.

I admit to having a vice for vises. I have a half-dozen in my shop, and just had a friend buy another one on my spec at a machine shop auction.

That is fantastically well thought out and apparently finaly machined! This truly is THE Device.

Comments are closed.