I’m new to the reloading world. However, I’ve worked in labs for nearly a decade. I’ve used everything from 0.0001-gram hanging-basket analytical balances to 500-lb rolling scales. As the lab coordinator, annual balances testing and calibration was one of my many jobs. I eventually knew my Mettler representative by name and was even on his “holiday card” mailing list. When I ordered my Hornady Lock-N-Load Classic Reloading Kit, I was surprised to find that it came with an electronic balance. Hmmm . . .

Within an hour of setting it up, I watched the display panel drift anywhere from 0.1 grains to 0.4 grains. Although the Hornady scale claims 0.1-gr repeatability, I decided to do some of my own testing by weighing a single lot of once-fired Winchester .308 cases.

I weighed all 50 in a row and recorded their weights individually. Then I did the same thing four more times and ran the numbers. I was amazed to find that the average repeatability was close to 0.3-gr. Some measurements were 0.7-gr off due to the scale drifting – not good and certainly not acceptable for loads destined for competition.

So here I was, working on a load development in 0.3-gr increments with a scale that has a 0.3-gr variance. Statistically and fundamentally speaking, that’s a nightmare. I decided to speak with a long-time reloader that spends many a lazy afternoon at the local gun shop. I asked him what he uses and what he would recommend.

Before I could finish asking my question, he spurted out “just get an RCBS and be done with it.” I took his word (and 30+ years of experience) and placed an ordered with Sinclair International (the “reloading” part of Brownells). In less than a week I had my new RCBS 1500 Combo.

Unpacking

To say the 1500 is well packed would be like saying [insert porn reference here]. By the size of 1500’s shipping box, you’d think Brownell’s sent me a sofa. Anyone familiar with precision scales and balances knows how fragile the load cells can be. I certainly appreciated the secure packaging RCBS uses as well as the sturdy, well-packed “overpack” that the guys and gals at Brownell’s added.

The package includes a “Quick-Start” guide, but set-up is easy and self-explanatory. I plugged it in, checked to make sure that the balance plate was level, and turned it on. After waiting an hour or so (to let the load cells warm up) I followed the instructions and calibrated using the supplied 50-gram weights to perform a 2-point calibration.

The fact that the RCBS uses two 50-gram calibration weights is impressive. Electronic balances are nothing more than a stabilized load-cell(s). They work by converting the mechanical force of a “weight” (mass and gravity) into an electrical signal. By using two calibration weights, you help define the calibration slope and this significantly adds to accuracy (not precision, that’s different) of the balance in your calibration zone. Balances that only use one weight “guesses” what the slope should be, usually by defining the [0x,0y] point. Stay away from balances that only use a single calibration weight.

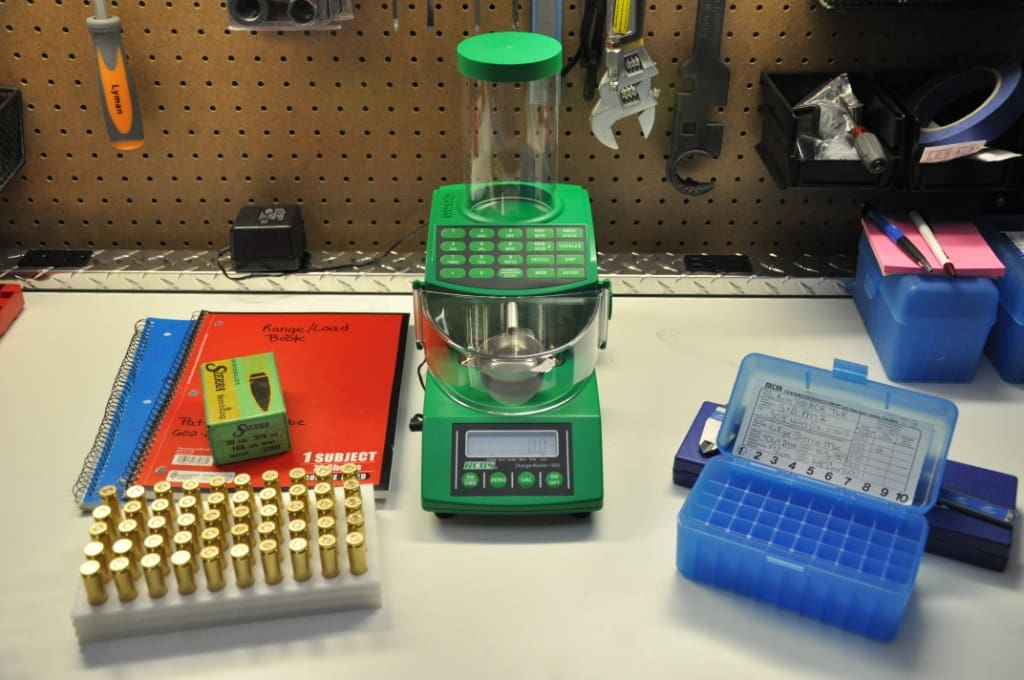

At the bench…

If you’ve tried to load match-grade ammo with extruded powder you know the perils of using a powder measure; the crunching, cutting, and inconsistent throws are all part of the game. This is why many handloaders use the “scoop & trickle” method (or sometimes the dump & trickle). It’s time consuming, and kind of a pain in the ass, but it ensures accuracy and consistency. The RCBS Combo couples the accuracy of the scoop & trickle method and the relative speed of a powder measure.

The RBCS allows you to input the desired weight. It will use up to four “charge speeds” and one “trickle speed” to hit the mark. You simply use the keyboard on the dispenser part of the combo and hit “DISP” (which stands for dispense, not display) when you’re done entering. In the video below, I show the speed at which the RCBS Combo can dispense 43.5-grains of IMR-4064 – a load commonly referred to as the FGMM “Copy Cat” when behind a 168-grain Sierra Match King bullet.

The average time for dispensing is around 25 seconds for the 43.5-grain dump of IMR-4064. Ball powder will trickle easier, as will “shorter” stick powders (Varget for example). For me, this is just enough time to dump the powder into a waiting case, replace the weighing pan, pick up and seat a bullet. The fact that the next load automatically begins to dispense after the weighing pan is replaced is one of my favorite features. It saves time and means I won’t accidentally “bump” the balance or hit the incorrect button.

After your loading session, the RCBS cleans up easily. You can use the powder drain on the side of the scale to quickly empty the hopper. Clearing the dispense tube is easily accomplished by simply hitting “dispense” again and allowing the scale to try and dump another load (make sure the weighing pan is in place). RCBS includes a small but long paint brush that you can use to brush any remaining powder out of the hopper and into the drain. Remember to close the powder drain each and every time you open it. Nothing is more frustrating than sending a quarter-pound of powder onto your reloading bench!

Tips & tricks…

Every now and then the dispenser will dispense a “clump” of powder and will overshoot the target weight. I have only really experienced this with IMR4064 – Varget, IMR 4895, and IMR 8208 have yet to “clump” and overshoot. You can knock some of the powder back into the hopper and let the scale “top off” the load to the target weight if you want. I prefer to dump the whole thing and let it dispense a full drop again – 20 seconds to dump a new load vs. 10 seconds to top off isn’t a huge time savings.

Some RCBS 1500 Combo users who use long stick powders will insert a McDonald’s drinking straw (or similar) into the dispenser tube, thereby covering up the rifling inside the tube. This prevents the long sticks from clinging up the tube and forming clumps. I haven’t tried it yet because I have yet to find a drinking straw that fits. Apparently McD’s now has larger straws then they used to.

Another something I noticed is that if you intend to seat a bullet while the next load is being dispensed, you need to make certain that the balance is isolated from the vibrations. I was having some troubles initially because I would seat a bullet and quite a few grains of powder would fall from the dispense tube, causing the load to overshoot. This can be remedied by moving the balance to an isolated bench or area, or by seating the bullet before the balance gets to the “trickle speed”.

When filling the hopper, make sure that the “scoop” portion of the dispense tube inside the hopper (i.e. the cut out portion) is facing down. If it is facing up, you will almost certainly get some powder shooting out of the dispense tube. No matter how slow I poured, some powder still make its way out of the tube. Simply use the “trickle” button to rotate the dispensing tube to the proper location. Even with the scoop facing down, you can get powder coming out of the dispense tube. I’m now in the habit of putting my thumb over the tube while filling the hopper.

Being a precision instrument, you’ll want to turn the scale on and leave it on. As it was explained to me by those in the know, load cells don’t respond well to constantly being turned on and off. By leaving the balance on all the time, they will be at a constant temperature (relatively speaking) and won’t drift as you start weighing loads (and ultimately heating up the load cells). It is appropriate to turn off the balance (via the power button) when you are moving and/or storing it. Just remember to give it a few minutes after you start it up again to re-calibrate.

Speaking of storing, electronic balances don’t like temperature extremes. I live in the Phoenix area and in just a few months, temperatures will soar to 100+ degrees. Temperatures inside a south-facing garage can reach 140 degrees during the hottest months. When we get to that point, I’ll make sure to start storing my balance (and powders and primers) inside. For those who live in areas with more than two seasons, you need to make sure that the balance is protected from the elements. Those of you with heated garages or work sheds can likely get away with never having to store the RCBS. Others may not be so lucky.

Conclusion

The RCBS is a great addition to any serious reloading bench. While many old timers will say that they can beat the speed of the RCBS, I really don’t see the need to. I reload for the cost savings and to be able to customize loads specific to my rifles. I also reload because I enjoy it – I actually find reloading almost as enjoyable as shooting. I’m not in a race and don’t need to reload at a blistering pace.

The RCBS 1500 Combo has a lot of features that I don’t use – load memory for example. This isn’t because they don’t work well or because they aren’t valuable, but because I’m only loading 6 different loads at this point and don’t have the need (yet). You can also separate the dispenser from the balance, but again – I have no need at this point.

Pros:

- Fast & accurate powder measuring

- Easy to use, maintain, and calibrate

- RCBS quality (although should you have a problem, Brownell’s has you covered!)

- Well-laid out buttons and features

Cons:

- At around $340 retail, it’s pricey

- Can be finicky with extruded (stick) powders

- Much more delicate than a powder measure and trickler

This sounds great, but the price is a little more than I could justify myself. Okay, a LOT more. I guess I’ll be stuck in the ‘measure and trickle’ age for a while.

It has been a few years since I did any reloading, so I’m wondering – what in your lab experience are the relative advantages and disadvantages of using these electronic scales to using a mechanical type scale (e.g. a beam scale)?

From what very little I know, I’d be much more comfortable working up a precision load with a triple-beam scale than an electronic. I’m in East Texas, no Arid-zona, but our temperature fluctuations even in the house can range quite a bit between the four seasons. (Not-yet-summer, summer, still-summer and Christmas.)

@Graybeard – As with any technology, you have your pros and cons. You also have your lovers and haters. Beam scales are great and every 8th grade science lab should have a couple. They’re cheap, relatively accurate, and durable. They are less sensitive to environmental factors like wind, especially the dampened models. However, they are also slower and subject to “user error”. Contrary to popular belief, they do require some maintenance and a reseaonable level or protection.

Electronic balances aren’t dampened (some analytical balances are but you don’t want to use them for reloading) which means that they can drift up or down with a measurement. Most of the lab-grade balances I’ve used have settings where you can adjust the sensitivity to take environmental factors into account. Electronic balances are typically more fragile, expensive, and can sometimes be finicky when other electronic devices are nearby. However, they are much faster to use and have very little “user error” associated with their use (no guessing where the needle is).

Some will argue that one is “better” than the other, but in reality this isn’t the case (I find that it is mainly the mechanical guys honking on how accurate or awesome their balance is). One may be better for a particular application than the other, but neither one is a clear winner. When I worked in the semiconductor industry, we used 0.0001g electronic balances for wet-chemical assay and analysis. Our products were being used by some of the biggest semiconductor manfacturers in the world (actually, all of the largest manufacturers) and we were in the ppb/ppt assay range.

Thanks, Patrick.

I suspect that if one is into long-range competitive shooting, trying for sub-MOA groupings, and putting a lot of rounds down-range, then the speed/accuracy advantages would play more of a role in one’s considerations to purchase.

For an ol’ powder-burner like myself who just wants to make sure the lead gets into the deer in such a manner as to get the venison on the table, and who doesn’t mind taking the time to carefully read the scale, the ol’ beam-scales would be just hunky-dory.

You can actual get a beam scale from Scott Parker that is tuned to be sensitive to a single kernel of powder. However, inconsistencies can arise from how you read it, etc., and the advantage of an electronic scale is speed and repeatability.

I load for long range shooting (F-class). Using an electronic scale that goes down to 0.02gr, I can get extreme spreads and standard deviations of muzzle velocities down into the single digits or low teens, and my loads can hold less than 1/2moa vertical at 1000yds. It can be done with a beam scale, but it goes a lot faster with an electronic scale.

Here are some tips on tweaking a Chargemaster from accurateshooter.com:

General tips, including how to get it to dispense faster

Using a serrated straws

The Chargemaster seems to reliably sell for less than $300 at Natchez.

A Chargemaster will get you +/- 0.1 gr if you set it up right. If you want better, use something like a Sartorious AY-123 (or it’s predecessors the Acculab VIC-123 and Denver Instruments MX-123, same scale different packaging).

This scale also uses a strain gauge load cell, and is one of the few that can go down to a milligram (or 0.02gr).

I have an Acculab VIC-123. In my experience means it’s accurate to at least one kernel of powder (Varget and H4350 are around 0.02-0.03gr per kernel, H4831SC around 0.03gr, for example). It does like clean power and to sit on a heavy base like a slab of granite.

For long range, I use a cheap Lee powder measure to dispense low and trickle up on the Acculab using an Omega powder trickler, which works a lot faster than the traditional kind and has a drop tube long enough to reach over the balance. Alternately, people use a Chargemaster or similar to dump a load that is under by a couple of tenths and trickle up on an Acculab, again using something like an Omega.

People also use the Sartorious GD503 for reloading, which uses a magnetic force restoration load cell. It offers 0.005gr precision, which is way more than you need. However, the main appeal of such a device to me would be the fact that it drifts much less than a strain gauge load cell (my only complaint with the Acculab).

Here is a comparison of the “123” scales, the GD503, and the GemPro 500, which seems to be a decent scale for $170.

Excellent review!!!! Did your Hornady scale come with some sort of enclosure to prevent air currents from moving the scale, possibly causing the fluctuation in readings? I see the RCBS one has one.

@ Joe – no, the Hornady scale is referred to as a “pocket scale” and literally folds-up into the size of a graphing calculator. It sells for around $30-40 online and is a total waste of money.

nice machine….seems like over kill …I use a lee beam scale…over sencetive to the point of insanity but dead nuts on the money…. just my opinion

Note that RCBS often runs rebates where if you buy >$300 worth of stuff, they will send you $50 rebate. I did the Natchess route, bought $4 worth of other stuff to hit $300, so net cost around $250.

I’ve only had mine a short time, loaded a few hundred rounds. I love it. I had the problem where I have one load for 100 yards reduced matches, different load for across the course matches. Used to take me forever to recalibrate my Lee Perfect Powder Measure each switch. Now, I just type in a different number. With H335 powder (ball) almost every throw is spot on, and maybe 3% overthrow by .1 gr, which for my purposes is acceptable….sometimes I pour that one back in, or just use it.

Excellent article, very informative! Just getting into 1,000 yard shooting myself, couldn’t be more timely.

Ah,.. another fine piece of tech I can’t afford. But fine, nonetheless.

And let me ask,… Pat, how do you work in such cleanliness?? Your bench is so well lit and spotless.

I’ve had one of these for a couple of years now & wouldn’t go without.

I screwed a shelf just big enough for the Chargemaster to the wall 3″ above my bench to isolate it from vibration & the scale really does keep to =/-0.1gr whenever I check it against my balance beam.

I have not used stick powder in mine, but my buddy has and he had issues with it being over a few grains as it would drop another stick to make the charge correct…but the stick was too much.

As I don’t use stick powder I don’t have this issue at all. Pumps out the correct charge each and every time. For making hunting ammo every year or just loading up a bunch of range .223 or .308.. you can’t really go wrong.

Price is a bit of an issue, but with how well this works and how much time it saves, it’s well worth the price. If mine broke today, I buy another tomorrow.

Do NOT throw away 300.00. It works for a LITTLE WHILE. RCBS WILL NOT REPAIR THEM OUT OF WARRANTY..

So the same as your microwave, television, or tablet?

I have been hand loading since 1984. 257 to 460 caliber. Kind of set in my ways. I hunt with a bow and shoot rifles for fun and to challenge myself. New technology in rifles, bullets, powder, optics, etc. deserve a precise hand load. I find it easier to develop precision loads using this instrument. This tool is not “cheep” it is an investment. Worth every penny to me. Good Shooting!!

Comments are closed.