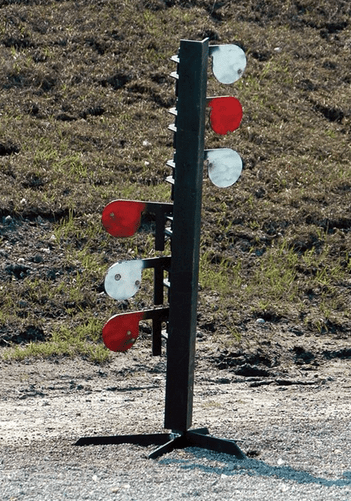

Press release from actiontarget.com, makers of the world’s first double decker :

With more and more companies and individuals manufacturing steel targets, the water has become increasingly muddy where accurate information is concerned. With technical data provided by the American Iron and Steel Institute in Washington D.C., this report is designed to cut through the recent hype and establish a basis of fact for accurate evaluation and comparison . . .

What Is Steel?

Steel is an alloy metal composed of iron and varying amounts of carbon and/or other elements such as chromium, nickel, tungsten, manganese, and so on. Steel with specific properties and characteristics is created by adjusting the overall chemical composition or by altering the various production processes such as rolling, finishing, and heat treatment.

Because each of these factors can be modified, there is potentially no limit to the number of different steel recipes that can be created. Currently, there are over 3,000 catalogued grades or chemical compositions of steel available. Steel can utilize a wide variety of alloying elements and heat treatments to develop the most desirable combination of properties.

Steel Hardness and Quality

For steel targets to be functional and safe, they should be made of high quality through hardened steel that has a Brinell hardness number (BHN) of at least 500. The steel must also provide sufficient strength, toughness, and impact resistance. The Brinell hardness test depends upon the resistance offered to the penetration of a carbide steel ball (1.6 mm diameter) when subjected to a weight of 12.6 kg. The resulting hardness value is computed as the ratio of the applied load to the area of the indentation produced. This test is accepted as a worldwide standard for measuring the hardness of steel.

Truth – There are 2 Factors that Affect the Hardness of Steel

The first is the amount of carbon and other alloying elements in its chemical composition, and the second is the manner in which the heating and cooling of the steel is manipulated. These factors are determined at the most fundamental level, and affect the finished steel as a whole.

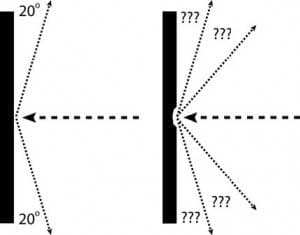

[Left] Hard steel with a flat surface will create a predictable splatter pattern. [Right] Soft steel with an uneven surface will cause unpredictable and unsafe ricochet and splatter.

Truth – Steel Hardness is a Critical Issue

[Left] Hard steel with a flat surface will create a predictable splatter pattern. [Right] Soft steel with an uneven surface will cause unpredictable and unsafe ricochet and splatter.

The hardness of the steel is critical because only a smooth surface will generate predictable splatter patterns. Steel that is not sufficiently hard can develop pits, craters, dimples, and other hazardous deformations. When a bullet hits one of these deformations, it is impossible to predict where the splatter will go, thereby creating an unacceptable training environment.

There are many steel mills located around the world, but only a select few are able to produce steel that is hard enough and of sufficient quality to be safely used for steel targets. HARDOX / SSAB, Bethlehem-Lucas, Oregon Steel Mills, and NKK are major producers of such steel. Each of these companies may have minor proprietary differences in their production methods, but they all must make sheets of hard steel in essentially the same way.

Nevertheless, some suppliers of targets and shooting range equipment attempt to muddy the water and create perceived differences in steel quality where none exist. One particularly misleading claim refers to a certain company’s use of through hardened steel as opposed to merely surface hardened AR500 steel allegedly used by everyone else. We state the following with all possible force:

1. Action Target uses only high quality, through hardened steel with a Brinell hardness rating of at least 500, and we use it in every one of our ballistic steel products.

2. Action Target can also provide through hardened steel targets and other steel products with certified Brinell hardness ratings of 550 and even 600.

3. Despite the inaccurate claims, AR500 steel is NOT surface hardened. It is through hardened. Witness the quotes listed below from steel suppliers around the country.

Chapel Steel – AR500 is a quenched & tempered, through hardened, wear-resistant grade of abrasion resistant steel plate used for severe impact. (SOURCE: http://www.chapelsteel.com/ar500-ar500f.html)

Heflin Steel – Heflin REM 500 abrasion resistant plate is a premium grade wear plate, ideal for extreme abrasion coupled with resistance to impact. REM 500 plate is through hardened up to a 3″ thickness for maximum hardness and abrasion resistance.

Benco Steel – AR500 is a through hardened steel with high hardness for use where there is severe impact and abrasion.

(These companies are steel suppliers, not manufacturers or producers. They buy steel from the actual manufacturers like HARDOX / SSAB, and then re-sell it to their own customers.)

4. Any statements contrary to those above are simply untrue.

Be careful not to get caught up in the “more is better” mindset. Just because a Brinell hardness number (BHN) of 500 is good, it doesn’t mean a rating of 700 is better. While you must use steel that is hard enough for the task, going overboard only impacts your checkbook and not the product durability.

For example, ballistic tests have shown that the performance difference between steel with a 500 BHN and steel with a 535 BHN is so small that you can’t tell the difference with a bullet but only with a gauge. Also be aware that you can actually use steel that is too hard and too brittle for ballistic training purposes.

TTAST…sonds like another website is fothcoming.

Still on the fence about getting a steel target. How safe are they for pistol ranges (7-25 yards)?

Based on experience, never felt a splatter at 15-25 with pistols .22lr through .44 special/.45acp. Wouldn’t personally be comfortable closer than 15, but I have nothing concrete base that discomfort on.

Spent my March ammo budget on one when I couldn’t find any ammo in town. Very happy. Equal to the target’s role in reliability of splatter/ricocet is bullet composition, I haven’t had any problems yet with my FMJ or HP.

USPSA rules min 21 feet for handgun. As an RO have been fragged on occasion at between 21-30 ft, usually with low power loads and lead bullets.

Sounds about right. I’ve shot steel with 180 grain .40 cal JHPs a bit closer than 10 yards and felt splatter. I wouldn’t get closer than 10 yards under training conditions. I’ve had coworkers get minor cuts on their bare arms from pieces of bullet and jackets at that distances. At close range, a smooth and hard steel target is critical. At 200 yards or so, not so much.

Steel targets are safe for pistol if you’re at least 10 yards away. Shooting steel gives you some of the best training that you can get, since you have instant feedback as to whether or not you hit your target. That way, your brain knows right away whether to adjust the way you shot, or if your shot hit it’s mark.

In my opinion, the Evil Roy line of targets by Action Target are the best portable steel targets in the industry. Pick one up for around $160 and try out shooting steel. You’ll probably end up getting a lot more after that.

I use one of these and I like it a lot: http://www.ar500-targets.com/ProductDetails.asp?ProductCode=stand-large …some of their other targets are looking very nice these days, and I’ll probably have to pick up more.

I purchased a Grizzly Targets pepper popper based on the TTAG review, but the side I shot is full of craters and missing chunks. Demolished. The back side is okay but there are a couple of bulges. Maybe the target they shipped me wasn’t actually hardened??? I need to contact them — could have been a mistake. The targets I have from the site linked above have been hit many hundreds of times and are no worse for the wear.

BTW — flat bullets are usually found sitting right at the base of the target. I have never, ever been hit by anything coming back. They seem to either squish and drop straight down, or totally disintegrate into bullet powder.

I use target A36 targets for 9mm, .22lr and .45 at less than 10 yards on wood posts and shepards hooks and have never had a problem.

AR500 for rifle.

Salute’s steel targets are ultra hard / durable and have a 30 degree cant. I’ll be putting a review up in a few weeks once I shoot the living hell out of one – but if their ads are to be believed you should be totally safe with any handgun cartridge at those distances.

If I was setting up a commercial range I might consider buying

targets; but steel target are just too easy for me make. I take

used snow plow blades and cut them up. Each one makes 10-15

targets. If/when the targets are destroyed, a quick trip to a

scrap pile is all that’s needed. If I want the targets to fall when

struck I weld on a $2 steel hinge. Works great for rifle and

larger pistol rounds.

A note of bullet “splatter”: if the target moves or rotates in any

way the splatter WILL NOT look like the picture in the article.

The steel and movement is made at a set value, usually for rifles

or pistols. Use of bullets with more or less power than the

intended rating will also cause a difference in “splatter”.

Usually the differences aren’t enough to worry about though.

Yea, I’m a do it yourselfer on steel targets. Take a plate of cheap carbon steel and torch it till its red hot then quench it in cold water a few times. Works great. When it wears out – just make another one.

I’m not paying 399 for a dualing tree stand from action target. I could get a handgun for that price, or a small box of ammo.

I could get a handgun for that price, or a small box of ammo.

Heh. I see what you did there.

I like steel and self healing targets reactive targets are good training and allow for realistic combat style training.

So, what are the circumstances that can return most of a bullet back at the shooter, like the famous .50 video, for instance?

I’ve had a 45FMJ bounce off a hot water tank and nail my shin. Nasty bruise. The steel targets at my range have a minimum 21 ft distance, but I’ve still had 357 magnum splatter hit me. Never with the 45.

Why not use frangible ammo? Then all you’d have to do is keep your mouth shut when you’re shooting steel at close range so you don’t end up with a mouthful of copper dust.

When did frangible ammo become cheap? Or due to the extreme light weights of the projectiles, mimic the recoil of a traditional bullet?

http://ingunowners.com/forums/bobcat_steel/249185-fragmentation_patterns_off_of_steel_targets_pic_heavy.html

Great write up (with pictures!) on mild steel vs. hardened steel targets with pistol, rifle, and shotgun rounds.

I shoot steel targets, quite often. There is a nice indoor facility nearby, their range has movers, dueling trees, etc. Shooters are required to use frangible ammo, which fortunately is actually cheaper than Walmart FMJ (if you are lucky enough to score any), since the demand for this training ammo is pretty low, they always have a good supply, and @ $21/50 for .45 acp, I can afford to shoot quite a bit.

The only downside is that these loads leave a lot of residue from the projectiles themselves. Their not dirty like cheap wolf or similar, but you have to clean your weapon thoroughly after each session. The only gun I won’t shoot there is my HK P7, as I don’t want that metal residue getting into the gas port in the barrel.

Shot steel targets in Alabama about 20 yeas ago. We were at least 30 feet back and could hear fragments hitting in the pond even further back.

I make my own. Steel plate, 3/4 inch mild cut into 8 inch square drop plates for my pistol at 15 yards or 15 inch round gong for ranges over 30 yards. I get em from the local scrap yard and just hang them from a nail on a post, taking care to set them at an angle from the vertical to handle the ricochet. Cheap as hell (except for the acetylene) Been using this formula for over 8 years counting and have not had a single untoward incident to date.

“AR” steels (AR-400, AR-500) aren’t really intended to be bullet-proof or even bullet-resistant. The original engineering intent behind AR-class steels was abrasion resistance for use in equipment and implements used in earth moving/working.

For example, when my backhoe bucket gave out, I had it rebuilt, with strips of AR-400 added to the outside of the bucket to extend it’s lifetime when digging through layers of caliche. I fully expect that bucket to outlast me on this earth. I used to use 2″ wide “pads” of AR-400 on a five shank ripper to extend the life of the shanks. Works like a charm in highly abrasive soils. Adding strips of AR steel was faster and gave more complete coverage than my spending a week putting beads of Stoody 31 hard-facing rod all over the bucket.

A BHN of about 500 is in the Rockwell C range of 50 to 51 or so. (quick rule of thumb when dealing with hard steels – divide BHN by 10 to get a rough idea of what the Rockwell C is before you turn on the mill or lathe and engage your HSS tooling…). BHN of about 500? Might not want to try using HSS to cut it.

OK, so having a rather hard plate, through-hardened at the steel mill, sounds sexy, right? Well, yes, until we start considering how we’re going to cut this material. Using gas axe will result in destroying the heat treatment in the “heat affected zone” on either side of the cut – of both the piece you want, as well as the parent piece of plate.

Next most common cutting tool would be a plasma table. Still, you end up with heat in the cut, just less than a gas axe. The big issue is in destroying the heat treatment of the parent part of the plate – which, in a steel shop, might not be destined to become a target. You, the buyer of the smaller piece of steel, are going to be charged for the wasted area on the parent plate that has lost it’s heat treatment due to your cut.

Now we enter the realm of big bucks cutting machines – industrial lasers and water jet tables. The latter technology leaves the steel’s heat treatment unaffected… but is pretty spendy technology. A large water jet table might cost a steel shop $100K+… and that’s the second part of why these targets cost so much. Someone has to pay the bill on that machine.

The irony is that there are steels made for explicit ballistic penetration resistance and there are NIJ/DOD standards for testing these steels against rifle ammo. But none of the target manufactures seem to want to use them… so they continue to peddle targets made out of steel intended for the earth moving and tillage industries.

I’ve had peeled 9mm and .45acp hit me at ranges from 21 – 25′ when hitting steel knockdown plates. The whole jacket hit me (no lead). Definitely need to wear eyes and ears using steel plates.

Wait… can I buy some hair formula from you?

No matter if some one searches for his essential thing, so he/she wishes to be available that

in detail, thus that thing is maintained over here.

Not only do you have to worry about what steel you but but also the maintenance. If it gets dinged up or worn out you increase the likelihood of an errant ricochet. With Target Is Moving we created a moving target that uses cardboard targets. No ricochet – nothing to worry about.

Comments are closed.