TTAG recently reported on the contract awarded to Colt Industries to manufacture 12k 1911s for the U.S. Marine Corps. soldiersystems.net had a look through the official TEST REPORT FOR THE CLOSE QUARTERS BATTLE PISTOL (CQBP) BID SAMPLES, PHASE II and reports that “Guns 11, 12, 14 and 15 (1-10 were not fire tested) fired 12,000 rounds before being deadlined due to visible safety-critical cracks found in the slides. Each slide had cracks in the same location, but they varied in size.” Huh. I wonder if Karl Lippard’s entry would have failed. [h/t thefirearmblog.com]

Really. I wonder how a Beretta model might perform?

Gun ranges tell me that Berettas are notorious for breaking, cracking and generally falling apart.

The myth of the Beretta M9 breaking after high round usage was busted a long time ago… I wonder why people still think that way about them. It’s a fine firearm.

No, it isn’t. It’s the worst firearm I’ve ever had the misfortune of being issued. It’s utter and complete shit, and if you don’t think so, you haven’t used it.

Yeah. Okay.

the beretta is a fine handgun. I dont believe the bullshit about them since my Beretta functioned just fine.

Agreed.

While I like mine, have qualified enough times with M9s pulled out of a rack still warm from the prior shooter, and have seen others on my relay and other relays do the same, I also wonder where this “legend” comes from. I wish some range blocks, OICs and actual no kidding unit armorers would chime in here, not anecdotal users (self included).

All firearms have a finite amount of rounds in them, so to speak. I’d expect to see busted frames on range pistols, abused week in, week out. Test fireams, while abused, I suspect see nowhere the abuse that unit weapons do. IMNSHO,

Please…tell me what gun ranges seriously say that. Just because the oh-so precious 1911 cracks in half after its “breaking-in” period, doesn’t mean the service pistol is a piece of crap.

yeah in the 1980s when it was being tested by Navy SEALs.

Anecdotal to be sure, but I don’t know anyone with a failed “Made in W. Germany” Sig.

One of those turned up at my friendly neighborhood arms dealer a while back.

Cash was a little tight at the time, but I’m still kicking myself for not grabbing it.

With a “Made in W. Germany” stamped slide? You got to pull out the stops for that. I have no idea whether it will ever be collectible in the sense of being worth more than it is worth, but I think it is a piece of history that happens to be a contender for the best full-size double-stack 9, OF ALL TIMES!

So long as it is kept free of dust and dripping with oil, the Beretta should perform fine. 😉

Huh really? because I’ve personally seen multiple locking blocks fail on the range.

A report on the military M9 from last year touted that MANY m9s are still using GEN 1 locking blocks, which are prone to fail and the military was having a third party manufacture GEN 1 locking blocks, perpetuating the problem. Anyone with a gen 2 or 3 block knows they run for an eternity.

Also, to all morons who still spout the Navy Seal incident. One gun… using hot submachine gun ammo, had a slide fracture. Those problems were fixed soon after with the FS pistols. People who get their opinions from shooting rack guns from a range obviously don’t know how many rounds are through those weapons and I doubt they are maintained.

I used the m9 on duty… never had an issue… and I shot A LOT.

Which maintenance schedule were they on for these tests? The Israeli? Follow the link (if you haven’t already) to get more views of the damage.

The M9 is fine. The Army units I have been in treat them like crap, fire them dry, with pitted barrels, and no bluing on large parts of the weapon, and they still ran. I dare say, there are no weapons in the world that would withstand the neglect most military arms rooms subject their M9s (and m4s for that matter) and as importantly the magazines to. The Beretta’s design is clunky, and the safety is a pain, but it was perfectly reliable for me and every soldier I worked with.

PatriotismOperator Error is the last refuge of a scoundrel.Failures can be blamed on user error even when the product is a complete piece of shit

I envy you if you’ve ever fired a Chauchat (at least for the novelty value – I don’t like failure-prone designs, though). However, for years that article has stated essentially what CouchPotato is saying – the Chauchat might have gotten a reputation for the “world’s worst machine gun” merely because of its ubiquitousness in those conditions. There may have been worse designs that never made it to the field.

A good example of a weapon that got a bad rap might be Tokarev’s SVT-40 (and possibly its competitor the AVS-36).

At 12k rounds? That’s not even a week of training on a hot schedule. Time for someone to lose their jobs.

My GSG 1911 is 4 months old and about 2000+ rounds through it. The slide failed on the Left side between Ejection hole and Dove Tail. I sent it back to Tactical. So far the say 4 to 6 weeks until they can look at it. The white line in the Photos are the natural Aluminum not enhanced in any way. Fortunately I was wearing Glass at the time of Failure, as my face was splattered with shards.

John F

Lake havasu, Az

928 680 4994

http://forums.1911forum.com/attachment.php?attachmentid=84158&d=1342189126

http://forums.1911forum.com/attachment.php?attachmentid=84159&d=1342189168

The USMC is part of the Navy. Navy SEALs swear by their SIG pistols. Why not give the Marine nice new SIG P220s for less money?

Them fighting words. Part of the Department of the Navy, not part of the Navy. There is a difference.

I repeat-

*facepalm*

I repeat: should’ve gone with a Glock 21 or Glock 30.

If they felt the need for additional safeties, Springfield XD45 or USP .45 would work too.

In fact the USP kind of reminds me of an overbuilt 1911. For those that don’t like the trigger, there are a multitude of different set ups you can have. I love my USP .40 Compact with the light LEM trigger. Trigger pull is almost as light as my custom 1911’s!

I think they should have gone with the HK45C or the Mk24 Mod0 in milspeak. It has already been in service with the Navy end of things since 2008.

I think getting them to adopt a striker gun anytime soon would be one hell of a challenge- but yeah, there are any number of tested, traditional autoloaders chambered in 45ACP that would ably do the job. In addition to the HKs, the P220 certainly comes to mind.

Remember Military contracts go to the lowest bidder……

Which is how we know that Hi-Point currently has no plans to produce a 1911. 😉

To the lowest bidder that satisfies all the specs and requirements. That includes reliability and endurance requirements. So, all else being equal, would you suggest the government purchase from the highest bidder? I would love to see the headlines “DoD wastes tax payer treasure by overpaying on contract”.

Sorry for the abrasiveness, but the old “lowest bidder” argument is tired.

The problem is that the lowest bidder doesn’t always put out the most reliable product. 12,000 rds and a crack in the frame? That never happens in an HK pistol. And the real problem is when those pistols break, guess what, more money is spent replacing the pistol. Short term cost doesn’t necessarily equate to long term cost, just like when you purchase a vehicle. Not all firearms are equally made.

I say again: “To the lowest bidder that satisfies all the specs and requirements. That includes reliability and endurance requirements.”

The lowest bidder must satisfy the reliability requirements. Theirs may not be THE most reliable product (and then maybe it is), of course, but unless you say that we purposefully set our reliability benchmarks too low, this is a non-issue.

Still, this was not a reliability failure, since the weapon may continue to perform as intended EVEN with the failure depicted. Do we expect that frames, receivers, etc, will fail at some point? Yes. Far beyond normal use, and normal wear and tear.

We don’t look for bullet proof, million year endurance. We still need to feed our armorers, you know? 🙂

Off the top of my head, here’s three questions I’d be asking:

1. Why are there no stress risers at that point on the slide?

2. What is the alloy?

3. What is the heat treating protocol?

I’m noticing more and more that steels are being over-hardened in a quest for specmanship in the industry.

That is almost word for word what the gunsmith where I work said when I talked to him about these 1911s failing.

Monday morning quarterbacking it….. That inside corner needs a larger fillet.

Textbook stress concentration region. Sharp corner is most likely not needed in that area, unless you’re going for a specific look, or it causes interference.

What was Nick saying about taking a metal gun over a plastic one for serious duty….

Lol. Be nice to Nick. But I do agree.

Folks, there’s no such thing as a free lunch. All materials have an upside and a downside. The problem in handgun (and rifle) design today is that gun buyers think they should get a gun that doesn’t need cleaning, never jams or stops for any reason, regardless of how badly it is treated, lasts forever, eats dog-shit ammo from foreign producers who can’t hold a size and (drum roll please) costs only $300 ($400 MSRP, so you think you’re getting a smokin’ deal) and can be bought at any Walmart.

I’m very sorry to have to be the one who breaks this news to the TTAG AI: the Tooth Fairy doesn’t work in this industry.

Since no gun is perfect we shouldn’t compare the relative merits of different materials or different designs? Why can’t we have a serious conversation about failures and failure modes of guns without the emotion tied to specific makes, models, materials or designs?

It just seems pretty plain that while not invulnerable, polymer frames don’t seem to be as sensitive to fatigue failures as their metal counterparts.

That’s true.

But with that comes a whole host of other issues, too. For example, you can’t modify a polymer frame much, if at all. What you got is what you get, done deal, end of story. You can’t repair or replace metal parts that are cast into the polymer frame, you can’t heat-treat it, you can’t weld on it, etc. Polymers are wonderful things. One thing they’re not is metal.

Now, I haven’t seen the parameters of the RFP, response, contract parameters, etc. I’m going to hazard a guess that there were parameters within the RFP that excluded a response of a polymer frame pistol. We can discuss whether or not these parameters were or are justified if we can see the RFP, but since we’re not seeing the RFP, we’re just left with what Colt’s response has been.

You can’t repair or replace metal parts that are cast into the polymer frame

Not all polymer guns have frame rails cast in to the frame. The FNP and FNX in 9/40/45 all have replaceable frame rails. The Styer pistol is the same way as well.

you can’t weld on it

I’m not a machinist, but what about plastic welding?

Lol the thing is, I don’t really care for welding anything to the frame. I simply want something that is dead reliable. I don’t get how this 1911 cracks at 12k rounds though, and a Sig doesn’t. I’ll bet that a Smith and Wesson 1911 is more reliable than this Colt, which is really weird considering the additional cost of a Colt -_-

My LGS wanted $1,300.00 for a Colt Rail Gun. I just didn’t want to pay that much for a 1911. Oh, and now that I have read this article, I wouldn’t pay that much not knowing when my frame would crack on the gun, i.e. round 152 or the 12,000 mark.

Hell, I paid $1100 (in CA) for my Kimber railed 1911 – best money I ever spent. Love that freakin’ thing.

Get an S&W scandium framed 1911 instead; money better spent imo

@Dyseptic

Sounds like you’re describing a Glock, there.

@matt:

Welding plastic is very different than welding metal in that no filler material can be added, not all plastics can be welded, with plastics its a one time only shot (i.e. once welded, the same material is changed on the molecular level and cannot be welded again in case of a bad weld) and the weld is often more brittle and weaker than the base.

The one report said the colt lasted longer than the springfield, the test must have been 12000 continously because my rail gun has 8000 rounds with no visible signs of cracks, but that is over three years.

How did the barrels look after 12k?

Dirty.

So is Eliot Spitzer’s escort (after 12k clients).

That rules out buying that Colt for myself (if possible) at some point…are those aluminum frames? I’m assuming so.

If they’re aluminum, then there’s a source of problems in a hurry. Aluminum is well known for work hardening under distortion.

However, from what I read in military contracting press surrounding the grant of this contract, I thought the slides and frames would be made from stainless, then treated with a spray-on-bake-on finish. This is what prompts my questions about the alloy, heat treatment and so on. There’s a wide variance in properties between stainless alloys, some are more corrosion resistant than others, some machine better than others, some work/strain harden more than others, etc.

I understand that most gun manufacturers use 416 stainless due to its ease of machining. It apparently has relatively poor corrosion resistance, gets brittle in very cold weather and possibly has sulphide “stringers” that can lead to failures.

But, it shines up really pretty!

There’s a reason why 416 is preferred for barrels, and it is because it machines up well. I’ve also seen 410 used.

There are several other alloys of stainless which are used in receivers, frames, slides, etc. 17-4PH is one example.

The armchair quarterbacks and gun rag readers who pose as experts in gunsmithing, machining, et al like to point out how 416 isn’t as “stainless” as other alloys. Of course, they’ve never actually tried to machine 304 or other highly corrosion-resistant stainless, so they have the luxury of pontificating on this point.

Want a really “stainless” gun? Go make it out of 304 stainless.

Get back to me when you want to drill and tap a screw hole. Maybe… just maybe… if I take enough pity on you, I might give you a tip on how to stop breaking taps off in the hole.

@Dyspeptic:

Totally agree on 304. It’s seriously good sh!t, IF you can machine it. Unfortunately, the machining process (from what I hear) requires the breath of a fish, the footfall of a cat, hen’s teeth and unobtainium.

Machining 304 or even 316 is really not that difficult, so long as you’re using the right cutter at the right speed with enough coolant. Ask anyone who’s ever made anything for a race car– it’s not rocket surgery.

@Mr. Lion:

Of course. What I was referring to (and I believe, D.G. as well) was the fact that 304 is not nearly as forgiving as 416. If I had a nickel for every guy I’ve seen snap a tool their first time working with 304, I’d buy The Truth About Cars. 😉

300 series alloys machine just fine if one uses the right speed/feed, tool geometry and coolant. 316L is wonderful to work with. People that have difficulty with these alloys are likely inexperienced or lack proper training.

Many factors go into determining the “best” material for a particular part in a particular application. This discussion could fill entire libraries.

Machining (in the general sense) 304 or 316 stainless is easy enough, when we’re talking about general machining.

The thing about gunsmithing that machinists often don’t understand is that many of the operations done in smithing are very light cuts with slow feeds. eg, profiling a custom barrel. Most gunsmiths are using HSS tooling that is hand-ground, not carbide insert tooling.

The key to machining 304/316 stainless is to not take a light cut. You need to take a real cut and use coolant to prevent work-hardening the surface of the metal.

This is where tapping a hole comes in. Most scope mountings on guns are done by hand-tapping a blind hole with fine threads. All talk by production machinists about how easy 304/316 stainless is (especially on CNC machines) now goes directly out the window.

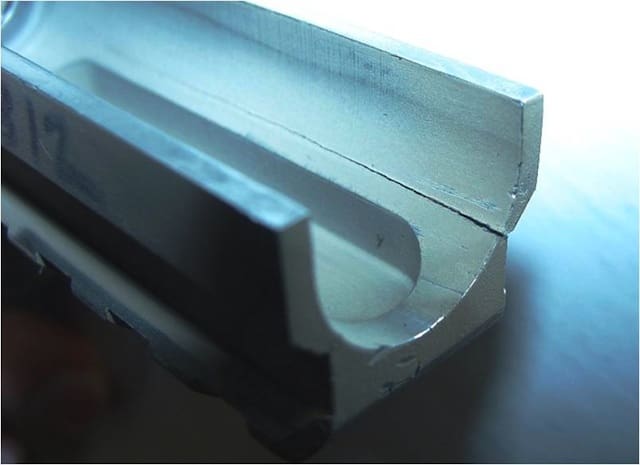

The cracks were in the slides? Why is a frame pictured at the top of the article?

I was wondering when someone would also see that.

i understand the desire for the 45. i just don’t see the desire for the 1911. never have, but that’s just personal preference.

These pictures are little more than flame fodder without knowing the testing methodology and the stated requirements within the contract. For all we know the pistols could have well exceeded very strenuous testing requirements.

A big +1

We don’t even know if these pics are authentic. Even assuming they are, we don’t know exactly what was done to them.

But, that doesn’t matter. Let the flaming begin.

The picture above is not the slide, it’s the frame.

It’s also on the “dust cover” and has no bearing or effect on the function of the pistol.

“… I wonder if Karl Lippard’s entry would have failed. …”

No way of knowing but my gut tells me his entry would’ve done just fine. I know he gets his balls busted about that four hundred yard stuff but he appears to have his machining and gun smithing capability down pat. I would absolutely love to have a Lippard in the safe.

… one of his guns. Not a member of his family. 😉

your tax dollars, now bailing out the unionized workforce at colt

Guess they should have bought XD 45s with thumb safetys. Twice the firepower, way more reliable, and lower maintenance costs.

Ever since I was a little kid I’ve wanted to own a ‘Colt’. Then I grew up and saw the quality. It’s okay, but I’m not forking out $1,400 for an average single action that’s no better than an Italian clone.

Glock 21 > Colt 1911

This has been fixed by Colt. In an attempt to lighten the frame they crated a binding spot for the spring. The slides were battering the frame to death.

Colt was allowed to fixed this later on in the tests and resubmit the new modded handguns.

My penis is fully engorged and I’m completely stoned on Vicodin.

Internet porn is the bomb, YO…………….

Chinqui !!!!!!!!!!!!!!!!!!!

Comments are closed.