When you think “Wilson Combat,” you think Bill Wilson and his love affair with the 1911 platform. The man is so ga-ga over Browning’s masterwork that he built an entire competition shooting sport around the gun, and now produces what are arguably some of the finest hand-crafted 1911 handguns the world has ever seen. But Wilson Combat does more than 1911s and the odd 92FS — they’ve been in the custom AR-15 business since time immemorial. One place they have yet to firmly plant their foot is in the .308 AR-10 market, which is something their latest creation attempts to fix.

I own a Wilson Combat Bill Wilson Carry handgun, and use it as my every day carry piece. I’ve owned that gun for about four years now, and I’ve gotten to know it very well. From the exquisite fit and finish on the moving parts down to the single ragged hole it puts in a paper target, the gun is a masterwork. So when Wilson Combat shipped out their AR-10 for review, the bar had already been set pretty high in my mind and I was expecting more of the same quality craftsmanship.

My first impressions of the gun were that this was exactly what I was expecting. The rifle is a sleek black beauty (not at all like a 1965 AMC Ambassador) with a satin smooth finish. Wilson Combat has their own proprietary finish called “Armor-Tuff” that they use on their guns, and it boasts the same general look and feel as things like Cerakote, but with some additional claims about lubrication. On the rifle, the Armor-Tuff finish made it feel like I was holding velvet instead of aluminum.

The attention to detail is what gets me, though.

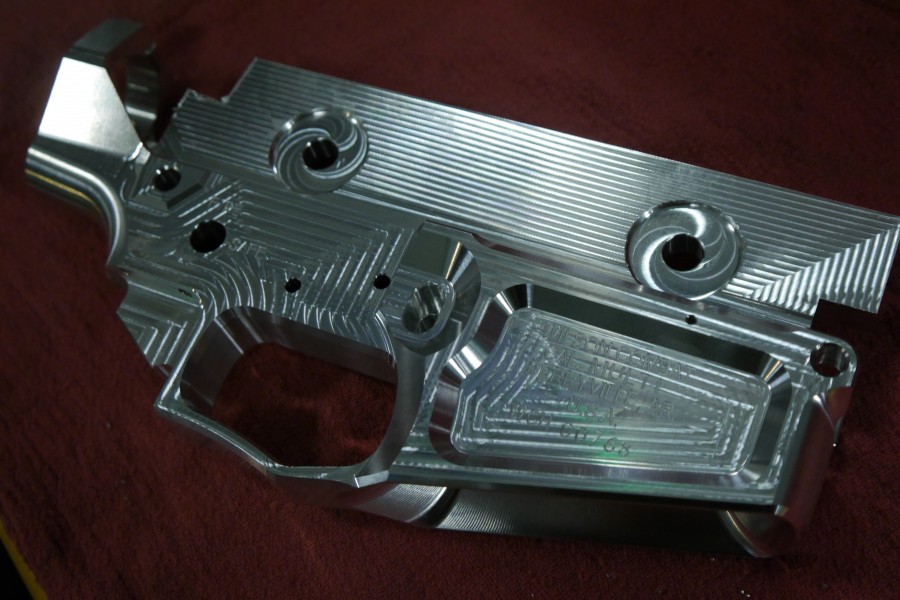

Wilson Combat is known for doing things the more expensive way because, quite simply, its the right way. For example, they CNC machine the entire lower receiver on these rifles rather than simply using a forging. They go a step further, machining out the magazine well instead of broaching it because that stresses the metal less. It also takes way more time, so you can understand if the gunsmiths take a little pride in their work.

I bring this up because one of the very first things I noticed was a little piece of paper. On an AR rifle, the dust cover is spring loaded and designed to rest on the housing for the forward takedown pin detent spring. This — over many many years — leads to some wear on the dust cover and some corresponding wear on the lower receiver. With the Wilson Combat .308, they shipped the gun from the factory with a tiny piece of paper wedged between the dust cover and lower receiver to keep them from rubbing. In all my years reviewing AR-15 rifles (admittedly not that many), I’ve never seen that before.

Right, enough ooh-ing and ahh-ing, on with the details. Starting with the business end of the gun.

Wilson Combat doesn’t make everything in-house. The receiver set is the only thing I know for 100% sure they make on site, and the barrel is similarly the only thing I know for 100% that they get from a supplier (when I visited a couple months back they were just producing their very first in-shop barrels with their brand new barrel machine, so that is subject to change). A couple accessories are obviously made by other companies, but WC selects only the very best. For example, they use Lancer magazines because “they just work every time” — and I use them in competition shooting for the same reason.

That said, the guns aren’t just a parts build. According to the folks at WC, very few of the guns they sell are off-the-shelf as-is builds. Most people want their guns customized to their specifications, which makes sense if you’re dropping this kind of money on a firearm. Review guns are an oddity in that manner, what you see here isn’t necessarily what you get from the factory — they have to make it “as is” for reviews. You can order it if you want, but why not make it your own?

For the review gun, the barrel is a fluted 18″ medium profile setup with a threaded muzzle. The barrel comes with an Accu-Tac flash hider, but you can crank that off and add whatever muzzle device makes you all warm and fuzzy on the inside. Surrounding the barrel is Wilson Combat’s own T.R.I.M. Rail system, which offers a full length top rail and user-attachable rail sections for your accessory mounting needs. The rail section mounting system is proprietary, which means additional rail sections are only available through Wilson Combat. I’d prefer to see something like keymod or even M-LOK to make things more interchangeable personally, as proprietary systems with marginal benefits aren’t really my thing.

The handguards also sport QD cups for slings, which is a nice addition.

Moving back to the receiver, the gun keeps looking sharp. The upper and lower receiver match up perfectly, as one would expect from a company that makes them both in-house. The triggerguard on the lower receiver is machined into the build, meaning no extra pins and no rough edges to worry about down there. Its flared slightly at the front, which allows more room for your finger to find the trigger and looks very appealing.

The trigger for this build is a 4-pound Trigger Tactical Unit (TTU) single stage affair made by Wilson Combat. Jeremy will be reviewing the trigger separately shortly, but in my opinion its a fine thing. The break is crisp and clean with very little take-up, something I definitely find appealing. However, for the build, I’m wondering if a two stage trigger might be more appropriate. The gun is designed almost as an SPR build, with long range shooting in mind. I’d think that a two stage trigger would be better suited for those long range shots rather than a run-and-gun single stage setup, but that’s really the shooter’s choice. And you can change that at the factory before its even built, so no biggie really.

The bolt is NP3 treated, which means it is slick and clean and stays that way. Running the bolt back and forth in the upper receiver is butter smooth, with not a single rough patch or hang-up. Perfect.

And then we get to the stock.

This gun was doing so well. It was hitting all the right notes, and then it all came to a screeching halt where the rubber meets the shoulder. For a rifle build such as this one, the normal expectation is that it would come with a Magpul PRS stock attached or something similar. With specs like these the gun falls squarely in the “precision hunter” category of rifles, somewhere a light and flimsy adjustable stock is simply not done. I could even see a Magpul UBR doing well here, but a standard carbine buffer assembly is simply not appropriate. It throws off the balance of the gun, and even visually seems like something is missing from the rear.

Wilson Combat does have some logic behind this move. Their assertion is that the end user will swap out the stock for whatever suits them best, and having dozens of SKUs for every stock imaginable isn’t possible at the factory. That’s true, and even reasonable, but we don’t review guns as they could be — we review guns as they come from the factory. And as it comes from the factory, the stock is definitely out of place.

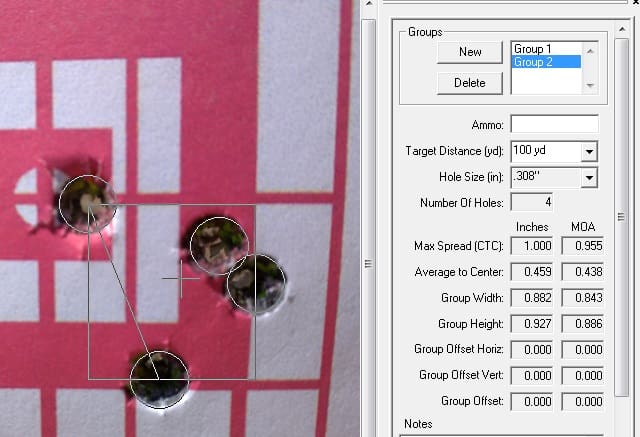

The real test of a gun is how well it does in practice. For that we took the gun out to the range, loaded it up with some Eagle Eye Ammunition (TTAG’s official ammo sponsor), slapped a US Optics 1.8-10x scope on top, and took a poke at a 100 yard target. The results were, to be honest, disappointing.

The best group I could get out of the gun at 100 yards was just a hair under 1 MoA. I thought something might be wrong with the gear I was using so I switched to Federal Gold Medal Match ammo and the Leupold scope I usually use for reviews, but the groups didn’t change.

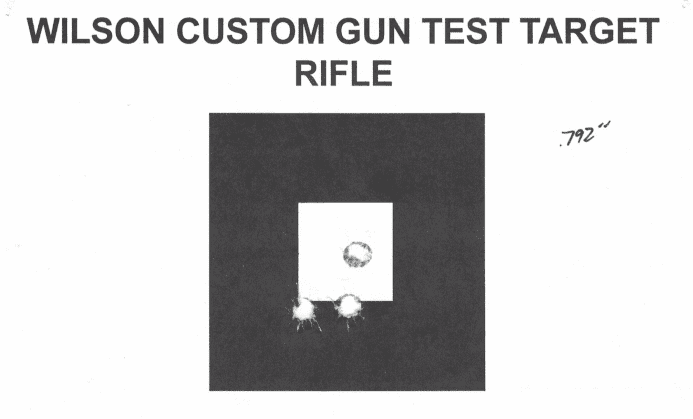

Wilson Combat tests every gun on their private range at the rear of the shop to ensure that it meets their accuracy standards. When I sent the gun back I asked about their guarantee for this gun, and their response was that it is guaranteed to produce 1 MoA or better 3-round groups. It succeeded, but not by much. I asked the Wilson Combat guys to run some rounds through it on their end to double check that my results were accurate, and the targets they provided were right around 0.8 MoA. The following was the best of the groups.

I’m not the greatest rifle shot in the world, but I’ve produced my fair share of cloverleaf groups before. The WC guys provided better 3-round groups, but the fact remains that the gun simply isn’t as accurate as the Armalite AR-10 we tested a few years back, and yet Wilson Combat’s offering is 50% more expensive.

There’s no doubt that a lot of love and attention went into building this rifle. The gun is aesthetically beautiful, and the fit and finish on every part is excellent. But when you’re asking a few pennies under $3,000 for a rifle that doesn’t shoot as well as a $2,000 rifle, I just don’t see the value. Heck, by the time you have a proper stock on the gun you’re already flirting with the price of a Les Baer AR-10 which comes with a Magpul PRS from the factory and a 1/2 MoA guarantee.

To me, performance is everything. Buying a rifle that talks the talk but doesn’t walk the walk is like buying a Ford Focus that has been chopped up to look like a Ferrari — it looks nice and might even feel nice, but you’re still going to be left in the dust at the starting line.

The saving grace is that Wilson Combat are starting to do their own barrels from scratch. The barrel shop is just opening, so if they can get their processes right this might turn out to be a good shooting gun as well as a good looking one in the fullness of time. But as it stands, meh.

Specifications: Wilson Combat .308 Project

Caliber: .308 Winchester

Action: Semi-auto

Barrel: 18″

Magazine: One 20-Round Magazine included (takes standard AR-10 mags)

MSRP: $2,995

Ratings (out of five stars):

Accuracy: * *

Out shot by a rifle that costs 33% less. And not by a little, either.

Ergonomics: * * * *

The handguards are great, the trigger is fantastic, and the action is butter-smooth. But the stock is flimsy and out of place on this gun.

Reliability: * * * * *

No issues. We fired hundreds of rounds without a hiccup.

Customization: * * *

Compatible with other AR-10 parts, but the rail sections are proprietary on the handguard.

Overall: * *

Given its current accuracy, I think the gun is overpriced. Give me a better stock from the factory and some improved accuracy and we’ll be in business. But in this case, what you’re buying is the Wilson Combat name and a pretty rifle — not an appropriately accurate one.

I could do better with a 699 psa 10

Boutique ar’s are ridiculous

+1. I have seen more than one ~$1k DPMS 308 do moa groups in American Rifleman’s 5 shot protocol.

“The man is so ga-ga over Browning’s masterwork that he built an entire competition shooting sport around the gun”

I don’t think so. If you check the history you might notice that the IPSC type shooting was built by Jeff Cooper and friends at Gunsight Raven, and Wilson Combat came after. The reason that they concentrated on the 1911, is that is what the winning shooters all shot in those days, and if you want to run a business you go to where the work is. If the pros are all shooting 1911s then that is what they want customized and made better to get some kind of an advantage.

The Author is referring to IDPA, which Bill Wilson founded in 1996 and made the CDP division to protect the .45ACP 1911. (CDP = .45 cal and no more that 8rds in a mag)

He and others broke away from IPSC & USPSA to form IDPA because they viewed USPSA as becoming to “race gun” oriented and no one was shooting single stacks in .45 anymore.

Had a few questions/issues with the article:

You say it is the right way – but there is no right way here. Machining it improves aesthetics only. If a person wants lower cost – nothing wrong with a forging.

Is this a display item or is this gun going to actually be fired?

Broaching (or broach cutting) is going to cut perfect corners. Nothing wrong with broach cutting. I thought broach cutting was better quality than cutting out small circles in the corners of the mag well with a mill.

… on a side note:

I agree with the accuracy. Should be better for what you are getting. It could be improved by working up your own loads to take up some more chamber and throat space – if you are into that.

I see someone did not pray hard enough to the Machine Gods! Boutique ARs like Wilsons have far more fickle Machine Spirits than your normal Lasgu— I mean ARs. Next time have the Martian techpriest bless it appropriately.

Hail the Omnissiah!

+1 internets for the 40K ref.

Blood for the blood god! Skulls for the skull throne!

Oh wait… Hold on…

For the Emprah!

Sounds like a steaming pile of “boutique paying for the name.”

I shot some sort of “Wilson Combat” 9mm compact one time and it was an atrociously unergonomic, slide biting jam-o-matic. But it said Wilson on it, so I bought it. (No I didn’t, but how many people just slobber over his name, like they do on anything that’s labeled “1911”?)

Yeah, I gotta agree with you at some level. Paying this much for a tool that is going to perform at the same level as something for far less is a bit lost on me. Now, some get quite a bit of pleasure for the looks of something like a really nice car that might not perform as well as something else but its worth it for them because of the name and the look of it. Depends on what you wanna spend your money on I guess so for the value focused customer or the one that buys for a specific purpose, there isn’t much use for the Boutiques. For those that want a “pretty” rifle i say go for it.

Actually, I’ve no issue with people paying extra for pretty.

It seems stupid, though, to pay extra for pretty AND give up functionality in the bargain.

SteveinCO: Sounds a lot like the iPhone crowd. 😉

How is cnc superior to a forging? Wouldn’t a forging be stronger?

Not sure what you are asking. Whether its billet, cast or forged, they all get CNCed. A forged lower is generally considered stronger than either cast or billet. CNC is simply the computer aided machining/finishing technique (as opposed to using more traditional manual machining).

This statement:

“For example, they CNC machine the entire lower receiver on these rifles rather than simply using a forging. ”

Is what I was specifically referring to. I don’t know what Nick meant either. Maybe that some surfaces are left as forged vs. machining everything? I don’t think I have seen anyone do that. Others have addressed billet vs. forging.

Depends.

Depends on the forging, depends on the bar stock that went into the machined receiver, and very much depends on the alloy and heat treatment of same. For aluminum, the issue is pretty well moot as long as we’re comparing the same alloy and heat treatment of that alloy.

For AR receivers, there’s not much test of their yield, shear or elongation strength, and the Young’s modulus is an intrinsic property of the material, so the only way you’re going to get a stiffer receiver is to use something other than aluminum in the first place.

Net:net – for 7075-T6 aluminum in AR receivers – there isn’t much difference forged vs. machined.

There’s a document that people who want to research this should consult, the “Metallic Materials Properties Development and Standardization” from the US DOT/FAA. It is available through the SAE and other engineering organizations.

Pretty sure we’ll just take your word for it. 😉

“Pretty sure we’ll just take your word for it.” LOL, and I agree with that statement.

Thanks, DG! I keep seeing all these claims and bragging rights about the superiority of all the “billet” lower receivers and have to chuckle. Sure, machining a lower out of a block of bar stock does give you more opportunity for creative refinements than using a forge Alcoa (or whoever is now drop forging them) but I was always under the impression that forging produced a stronger blank.

Appreciate your input!

PTR91 type rifle and then take a vacation with the money you saved.

Nah – unless you get the beefed up “sniper” versions, the average HK/PTR isn’t really up to more than about 2-3 moa. My HK91 had OK accuracy, but certainly couldn’t outshoot a quality AR in .308 (say, a Ruger SR762 or RRA X-series).

If you don’t like the AR platform, a DSA FAL would be a good substitute, and of course the M1A platform is noted for decent accuracy.

My shooting partner has a Wilson AR in .300 Blackout. Beautiful rifle and very nicely finished. Shoots well too, but I wouldn’t spend that money.

Nick, when the Wilson Combat barrel shop is up and running, will you give this platform with WC barrel another round of testing? I’m curious to see just how much better their own barrels are, possibly on the same level as the Les Baer. Thanks

I’d love to, if they let me.

You’d think they would want you to. Clear up a blemish on what is a pretty clean record. Just from a pure numbers standpoint, with all the readers you guys have I’m sure a lot of people use TTAG’s very thorough and completely unbiased gear/gun reviews to help make purchasing decisions. Its great advertising and I would want a great review for my product.

Nick, do you think the price of the gun will break $3k with an in-house barrel? By how much?

I think Wilson Combat is the Porsche of firearms industry. That being said, point A to B being the end result, I’m perfectly satisfied with a Camry.

CNC Billet 7075 receivers are harder and would theoretically and practically break before a 7075 quality forged receiver.

Meaning little to no flex in a billet can break under stress. You will get some flex in a forged product that will allow the metal to flex to a point before breaking

The Young’s modulus of both forms of 7075-T6 varies only slightly.

Young’s modulus is an intrinsic property of the material. The hardness has no bearing on it.

The tensile strength of bar stock 7075-T6 is higher than for forged – but only slightly. The shear strength is also higher too – but only slightly.

The hardness of both should be the same.

I look forward to the Daniel Defense 308 coming out. To me they are the sweet spot of build quality and value.

Though I agree that it would be desirable to get less MOA per dollar, they do seem to be giving you what was promised. Iif you want to measure your groups in tenth-minutes, use a different platform. Look at the other boutiques — Larue guarantees 1MOA, I don’t think JP promises any better. You’re not paying for accuracy, you’re paying for fit and finish. Les Baer has that whole 0.5MOA thing, but it’s only for the Grendel, right?

I have to nit pick a bit. 1 star for 1MOA from a semiauto seems a little unfair. I know it’s Gawdawful expensive, and I certainly won’t be ponying up the bucks for one, but 1MOA is objectively decent accuracy. Subjectively, you might expect more for $3k, but if I were spending 3k on a precision rifle I think I’d be looking for a bolt gun.

Just an opinion.

Yea, I was going to ask “just what do you expect for accuracy on a semi-auto?” but decided against it. So I might as well ask now. Just what do people expect for accuracy on a semi-auto rifle? And what are you willing to do to achieve it?

Hint: If you’re seeking a sub-MOA rifle (measured with five-round groups) and you’re not willing to load your own ammo… well then, I think you’d best buy some dentures and start wishing for more money from the Tooth Fairy.

Now, as to another beef I’ve had for a long time:

If TTAG wants to bark about accuracy below 1″ groups at 100 yards on a rifle, and 2.5″ and under at 25 yards for a pistol, then they should become objective and consistent in how they test accuracy. Most of the authors at TTAG don’t seem to understand how to do useful accuracy testing, and instead perform ad hoc testing that isn’t doing TTAG or the companies providing products for review any favors.

I agree, 1 star does seem a little low. I’ve bumped that up a star on reflection. However, I still stand by it being below 3 stars.

The star ratings are based on how the gun fares against the “average” firearm for that price range. When an Armalite AR-10 shoots a much tighter group for $1,000 less, there’s an objective measure that the gun does not meet the standard set for the amount of money you are paying. Accuracy should improve with price, not drop.

We are working towards fine tuning the standardization for accuracy testing. We’ve got an official ammo sponsor, so we have a level playing field with consistent ammunition. We’ve got a prescribed testing distance, so the group sizes are all comparable. The only real variables left are the optics (working on that) and the shooter. In short, we’re working on it. Even as-is, I think we do a better job at a standardized testing protocol than anyone else.

Without knowing the particulars of which chambers are in which rifles, I can’t speak as to why one shot better than the other. But I can tell you that freebore has an effect on accuracy, and different chambers in barrels, different length barrels, different weight barrels, etc will affect accuracy significantly once you get under a MOA. When the gun in question is holding only 2 MOA+ groups, then these other things are in the noise of the dispersion of the group. Once you’re under a MOA, now you’re into a level of accuracy where what used to be a footnote moves up to be a Level 1 heading.

I keep telling you folks to quit obsessing over the black guns and start reading or learning about benchrest shooting, because those are the people who have thrown down the tightest groups and who have learned the most about what it takes to do that. The benchrest people have, over the last 40 years, taught the rest of us in shooting what it takes to make a “one hole” rifle. They’ve done it, experimented, proven what works, what is necessary, how it can be replicated, etc. The rest of the shooting industry and shooting community, from varmint hunters to snipers, owe the benchrest community a huge debt for all the work they’ve done in the last 40 years or so.

The one thing every benchrest shootist will tell you is that when you’re under a MOA, you need to start sweating the small stuff. Ammo that works well in one rifle won’t group as well in another. Some barrels are faster than others. Some bullets will shoot tighter groups out of the same rifle, same powder, same primer, etc than other bullets. Chamber freebore matters, bullet seating depth matters.

There’s a reason why benchrest folks spend so much time obsessing over their loads, bullets, cases, primers, etc. That’s what wins them matches. The days when you could show up with a well crafted rifle and win with good factory ammo were over decades ago…

When I bought my Colt AR-15 Model 6724 back in 1997 for $1,300 I was able to shoot 5 SHOT groups well under a half inch with it using Black Hills factory ammo. I occasionally shot some groups very close to being 1/3 inch.

Taking inflation into account, I spent $1,900 in today’s dollars for it.

Because my 1,000 dollar predator pursuit shoots under 1 moa all day. Heck I get 1/2″ groups with Nosler Varmageddons. For $3,000 dollars I would expect at least the same.

I’d be surprised if accuracy didn’t improve with a better butt stock. Flimsy, jiggly, no cheek rest carbine stocks just suck outside of their intended use.

Meh. Sub-MOA accuracy is a weird voodoo dance between the minute particulars of the ammo, barrel, & action. Getting a rifle that shoots truly tight groups with factory ammo, match grade or not, has more to do with luck than the competence or technique of the manufacturer. Even on a well built gun, you will still probably have to load the ammo yourself to harmonize with the barrel if you want to get below 1 MOA.

It is a semi-auto gun firing not super specialized ammo, 1 MOA is damn good accuracy. There are simply limitations to the design of a semi-auto that it would be ludicrous to expect better than 1 MOA no matter how expensive it is. Now if it shooting a bolt-on in 6.5 Creedmoor or .338LM, it would be understandable.

I don’t know much about alternatives, but the bipod and attachment look rather ungainly. A more sleek, easier to clean, less likely to snag, more visually appealing solution is easy to imagine.

That was the first thing I noticed as well. Maybe Nick can comment on whether or not it comes with the rifle or he supplied it. I find it hard to imagine Wilson would ship a Caldwell with a $3000 rifle.

*skips review, goes straight to price*

HAHA, no.

Is it just me or is the caliber on the rifle denoted in Comic Sans? 6th picture down…

I love my Wilson Combat 308. It weighs less than 8 lbs. The Les Bear weighs over 11 lbs. 1 MOA is 4 inch groups at 400 yrds. If you want to shoot offhand, without any rests, for me weight is very important. With my Kahles 1-6 (17.6 ounces) and my Bobro mount (9 ounces+/- ) and a fully loaded 10 round mag (8-10 ounces) I’m still under 11 lbs. I can shoot that MO Man at 400 yards off hand without a rest. I can not do that with my heavier rifles.

Sorry, but as the reviewer said, your rifle is way overpriced for the level of performance that it delivers. Your scope is way overpriced at $2,200 too. Looks like you really like to throw money away.

And you brag about how lightweight your rifle is? Heck, to be under 8 lbs means that it only has a 16 inch barrel. And a rather lightweight one at that too. Even a stock Smith & Wesson M&P 10 is under 8 lbs, and it comes with an 18 inch barrel.

And you brag that your scope and mount ONLY weigh 26.6 oz? Dude, that total comes to 1.66 lbs!! On my 308 AR I have a Leupold VX-R 2-7x33mm that weights only 12.7 oz, and my Aero Precision Ultralight Mount weighs only another 3.2 oz!! That comes to only 15.9 oz in comparison, That is 40% LESS than your scope setup Dude. You have nothing to brag about there either.

Face it, you own an overpriced rifle that is clearly not worth the money that you paid for it. And it has no features really worth bragging about.

Anyone can get a NP3 bolt and carrier group. While the trigger is good, anyone can install that in their AR too. And that handguard? It is way hideous and way less ergonomic than other solutions that are available today. My rifle has a FAR SUPERIOR handguard on it: the Diamondhead VRS T-308:

http://www.primaryarms.com/v/vspfiles/photos/2352-2.jpg

I am surprised that so many just don’t get it. There is no such thing as a 1 MOA Gun, unless you know of a way to consistently suspend the laws of physics. Accuracy is a combination of internal and external ballistics as well as shooter ability. When all the planets line up you could count on less than 1 MOA performance from you Shooting system otherwise there will be uncertainties in the process. Please don’t forget the science no matter what you buy.

If you love to wear hoodies? so get this amazing Feel The Beat Hoodie Moreover, it has a hoodie-style collar with a pullover front closure and rib knitted cuffs to hold your wrist. All these amazing features make it one perfect casual outerwear to get compliments from your fashion friends. Discover now the best deals and amazing prices.

Comments are closed.