Muzzle Brakes. Advocates will sing their praises in terms of recoil reduction and taming muzzle rise, but Newton’s laws of physics extract a price for these benefits: namely increased noise and blast concussion. Personally, I’m a big fan of muzzle brakes because I shoot more accurately with lower recoiling rifles, and I love to see the bullet’s trace and impact. So when I first saw these new innovative brakes from Precision Armament, I knew I had to try them out. I ended up ordering two of their best-selling brakes – the M-11 and the M-41 – and now report to the armed intelligentsia.

Earlier this year, fellow TTAG writer Jeremy S. wrote an article about his pimped-out Mosin Nagant. Reading the article, I couldn’t help but notice that he had installed one of the most wicked looking muzzle brakes I had ever seen. Precision Armament? Who? Never heard of them. I clicked onto their website and started checking out their products – and quickly realized that these guys have some serious talent, and their prices are reasonable to boot.

Ok, so here’s the scoop on Precision Armament. The company is owned by two brothers: Matthew and Stephen Vossler. Matt and Stephen are mechanical and aerospace engineers who have a background making components for the aerospace industry. Two years ago, Matt and Stephen decided to follow their true passion and branch out into making high-end tactical firearms accessories.

The company is based out of the small town of Wellsville, New York, which is 40-50 miles southwest of the beautiful Finger Lakes region of upstate New York. Precision Armament currently has twelve employees, 6 CNC machines, and a very bright future. In order to set themselves apart from the pack, the Vosslers emphasize the use of the latest state-of-the-art 3D CAD, finite element analysis (“FEA”) software and multi-axis machining of exotic allows such as Tenealum® 7068. The company’s current product focus is on muzzle brakes and hybrid flash hiders, scope rails, and bolt knobs. The M-11 and the M-41 are two of their best-selling products, and I suspect their new EFAB and AFAB hybrid brakes will be well received as well.

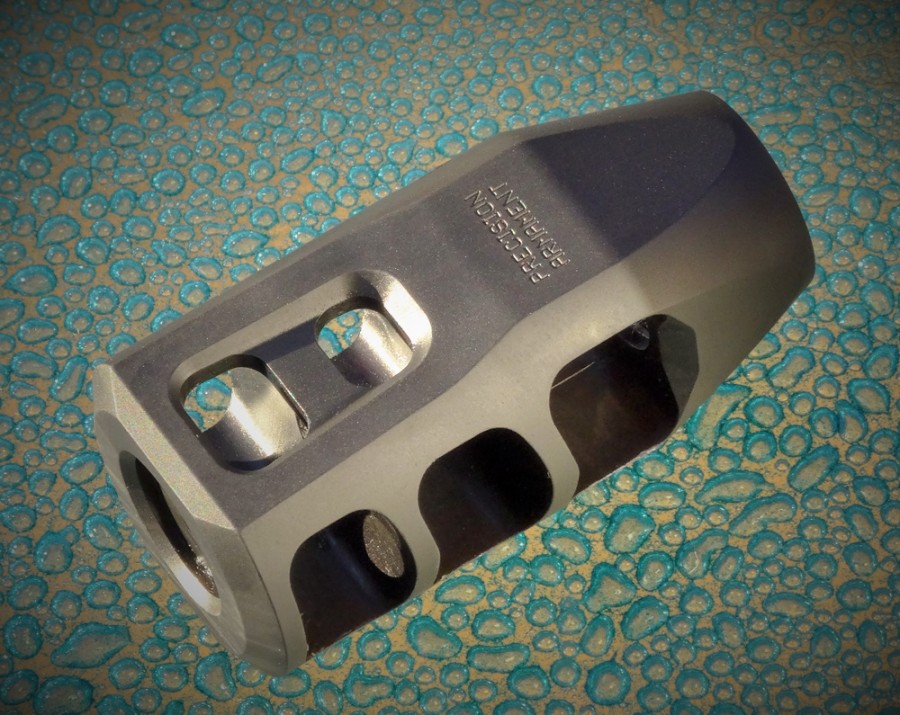

M-11 Severe Duty™ Muzzle Brake.

The M-11 Severe Duty™ muzzle brake takes the traditional “side-venting” approach to the issue of recoil reduction and adds a twist: two large top ports. It’s truly a little work of art, and reminds me of the brakes found on WWII-era German panzers. This is a brake that you really have to hold in your hand to fully appreciate. Besides the quality of the machining, perhaps its most notable quality is the gorgeous aerodynamic lines and its silky smooth satin polished feel.

But there is more to the M-11 than simple good looks. The brake is made out of heat treated stress relieved (“HTSR”) 400 Series Stainless Steel. This material retains good dimensional stability during the cutting process, and has more corrosion and erosion resistance that conventional chrome moly steel. The brake is also finished in state-of-the-art Diamond Like Carbon (“DLC”) in a low luster Matt Black.

The brake’s massive blast deflectors create three separate blast chambers. The first chamber (i.e., the one closest to the muzzle) is the largest, and each of the two successive chambers decrease in size. The last two blast chambers also contain large ports on top of the brake, so that gas is directed upward to keep the muzzle down. TTAG writer Jeremy S. captured this awesome money-shot of the M-11 in mid blast:

The blast baffles are only angled ever so slightly to the rear. In this regard, Precision Armament is making a deliberate attempt to balance recoil reduction against the negative effects associated with rearward directed noise and concussive effect. As a result, this brake is loud, but not as loud as other brakes I have used.

The M-11 is a non-symmetrical brake, and, as a result, needs to be properly “timed” or “indexed.” Traditionally, muzzle brake designers have taken two approaches to this issue. Companies such as Grizzly Gunworks use an allen screw clamp system to index their threaded brakes. While that system has the benefit of being easy to remove for cleaning, it does increase bulk, weight, and in theory could get stripped out. Precision Armament wanted to maintain the svelte aesthetics for the M-11, so it opted to use a set of custom sizing washers. Notably, Precision Armament does not recommend the use of crush washers, because of the inherent potential for misalignment.

In place of crush washers, Precision Armament designed the proprietary Accu-Washer™ Muzzle Alignment System. The set consists of a series of 18 individually marked washers, each of a slightly different width. Using these washers, the “timing” is adjustable from 0-360 degrees in 20-deg increments. The washers are precision machined from high strength 400 series stainless steel to a guaranteed thickness uniformity of ±0.0001. The precise tolerances of these washers guarantee the most accurate bore alignment possible. Because only one Accu-Washer is required for each rifle, the system avoids a “cumulative effects” problem that is commonly associated with peel washers and other multi-shim systems. It took me about an hour of sorting and trial-and-error fitting to get the timing right on my Savage Model 10 TR, but now that I have the correct washer selected, I can remove and reinstall the brake in less than a minute. The Accu-Washers work well, but some people will not like the fact that the washer remains visible once installed.

The M-11 is threaded for 5/8 – 24 threads and is produced to match one of four bullet diameters: 6.5 mm (.264 caliber), 6.8 mm (.277 caliber), 7.62 mm (.308 caliber), and 8.6 mm (.338 caliber).

Here is my summary of the advantages and disadvantages of the M-11:

Advantages:

- Good Dust Suppression for prone shooting.

- Does not exhibit tendency to loosen.

- Excellent recoil reduction.

- Relatively easy to clean due to large baffles.

Disadvantages:

- First time install is time consuming due to the “timing” issue.

- Louder than M-41.

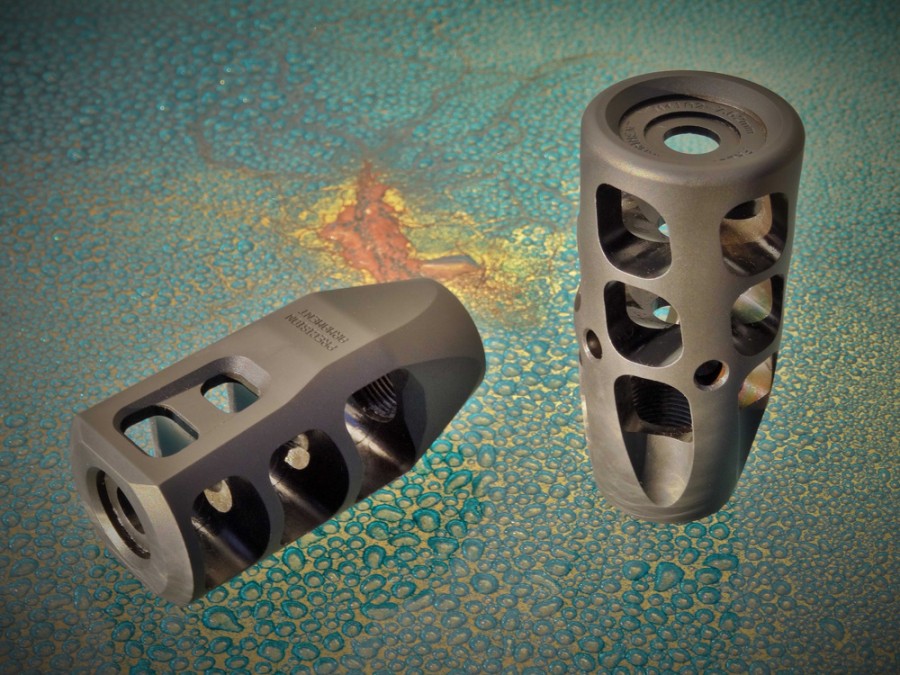

M-41 Severe Duty™ Muzzle Brake.

Spiral “axisymmetric” muzzle brakes have been around for a while, but with the M-41, Precision Armament takes the concept to the next level by enlarging the traditional small-diameter round ports into three sets of large 5 rounded rectangular helical ports. Combined, these ports create three separate blast chambers, just like the M-11. Unlike the M-11, however, the M41 designed to counter both linear and torsional recoil forces.

For a standard right hand (“RH”) twist barrel, the brake needs to apply torque in the same direction as it screws off. That, of course, means that the brake will want to loosen itself. Companies such as HK design their pistols with left hand threads, which solves that problem but creates compatibility issues. Precision Armament believes that the latter is the greater evil, as sufficient tightening with a torque wrench to (20 ft lbs) will be adequate to counter the loosening effect.

Nonetheless, to combat the “loosening” issue, you really have to install the brake to the torque specifications set forth in the instructions. Precision Armament recommends 20 ft-lbs, which is a considerable amount. By way of example, putting all your might into it bare handed, you may get 2-3 ft-lbs. PA does manufacture a wrench specifically for the job. You don’t need to put the barrel into a barrel vise to get it to spec, but it helps. We didn’t get it right on our first attempt, and almost paid the price. As the brake loosened, we noticed a sudden and distinct downward POI shift (12 inches at 200 yards). Fortunately, we were quick to diagnose the problem. I’d just glad we didn’t blow it off the barrel!

One really nice touch on the M-41 is the engraved “Precision Armament” logo on the front of the brake. It gives your target something to read while you dial in your dope! Ha!

The photo above shows the M-41’s helical blast chambers, as well the circular holes for the custom wrench used to loosen and tighten the brake.

The above photo shows another close up of the business end of an M-41. M-41 is threaded for 5/8 – 24 threads and is produced to match one of three bullet diameters: 6.5 mm (.264 caliber), 7.62 mm (.308 caliber), and 8.6 mm (.338 caliber).

So, to summarize the M-41:

Advantages:

- Symmetrical design: No need to “index” or “time” the brake to the barrel.

- Extreme reduction in felt recoil (slightly better than the M-11).

- Less concussion than M-11 and similar side-venting designs.

- In theory, it should be best for accuracy (but this is difficult to test and quantify because of difficulty in isolating other variables).

- Look great!

Disadvantages:

- Brake wants to loosen itself so important to install very tightly; use Loctite and a torque wrench.

- Gas vents in all directions: no dust suppression characteristics.

- Better for “bench” shooting due to dust issue.

- Uses proprietary $20 tool to install.

- It’s a bitch to clean.

So, the obvious question is: which brake do we like better? Although these are very subjective assessments, it seems the edge goes to the M-41 because it has slightly better recoil attenuation with less concussive effect. Neither of the two brakes had any noticeable negative effect on accuracy, and the light recoil may in fact indirectly assist in getting tighter groups. Having said that, if you shoot prone on dirt or sand, the M-11 offers far superior dust suppression as compared to the M-41.

Specifications:

Materials: HTRS-400 Series Stainless Steel

Finish: Diamond Like Carbon (“DLC”) Matt Black, or “in the white”)

Price: $120.

Ratings (out of five stars):

Performance: * * * * *

As I’ve said before, muzzle brakes aren’t rocket science; they represent simple Newtonian physics in operation. Nonetheless, Precision Armament is pushing the envelope to deliver state-of-the-art computer designed brakes that maximize strength to weight ratios.

Durability: ?

Hard to evaluate in the short-term, but PA’s use of high-quality materials, computer assisted designs, and precision tolerances gives me confidence that these brakes will last forever.

Value: * * * *

Overall, PA’s prices are very reasonable, with the possible exception of the M-41 wrench, which, at $20, seems overpriced. You can find cheaper brakes, but it’s doubtful that they will exhibit the same level of quality and workmanship.

Overall: * * * * *

A strong buy recommendation.

WANT

FYI in the upcoming super gigantic muzzle device shootout I’m going to be comparing and recoil testing over 30 different AR-15 (5.56/.223) muzzle devices. I think there are 3 from Precision Armament in it, including the smaller version of the M11 shown here (the “M11 SPR” for 5.56). They’re apparently working on at least one brand new brake and it’s possible it can squeak into the test in pre-release phase but I’m not sure it’ll make it in time. Testing is scheduled for the last weekend this month, and the article will probably be published on here in the first couple weeks of November. I have brakes from all of the top names — surefire, AAC, battlecomp, ferfrans, JP, ares armor, bcm gunfighter, OSS, PWS, VG6, ALG, Miculek (dpms), silencerco, precision armament, gogun, strike industries, lantac, HERA, king armory, rainier arms, black river tactical, and others (like a $16 shipped one from Amazon.com)…

Really looking forward to that article. Have fun testing!

Amazing photos dude.

That M-11 is a sexy beast.

Waiting with eager anticipation on the big test. This is good stuff.

Joe, fantastic photography as usual.

Just as good, If not better…

http://wittmachine.net/

But ugggleeey!

Someone has a good sense of humor, lol!

I guess I don’t understand the “timing” bit, unless it just referring to getting it lined up correctly when screwing it on the threads so that the “up” vents are actually pointing up.

But it’s doubtful I’d buy one anytime soon, so not worth spending time figuring it out. They look very cool though, I just don’t have a need for one (yet!). A buttpad has tamed my Mosin enough (at least for the amount I shoot it in a given session) and I don’t have anything else that needs it.

Yes, “indexing” or “timing” are words used to describe exactly what you state: “getting it lined up correctly when screwing it on the threads so that the “up” vents are actually pointing up.” Perfect description. Thanks!

I have a M-41 in stainless on my Savage 110 BA .338 Lapua. Its mated to a 27″ stainless heavier than factory taper barrel. The M-41 is by far superior to the factory brake in all ways. Its lighter, smaller and reduces recoil much better. I cant claim that it keeps me on target in the scope but there is no brake that can or will when dealing with a .338 Lapua. There are a lot of gimmicky brakes out there that catch our eyes but fail to meet form fit and function. These brakes are the real deal in quality, material quality, machining and performance. Five years and three after market brakes later I managed to shoot out the factory barrel. With over 500 rounds through the M-41 I feel I have ample experience to claim the M-41 is superior. Well worth the money spent.

Comments are closed.