Here at TTAG, political stories are the flash that brings in temporary traffic, but our gear and gun reviews bring readers in droves for years to come. In fact, the highest traffic gun review in Q1 2013 was actually written in May 2011. Truth be told, I’m a big fan of writing gear reviews. I am also a huge fan of writing reviews of nearly every product a company makes. Which leads us to our preview of the KG Industries cleaning and lubricants range. The plan is simple. Over the course of the coming months, I’ll be posting reviews of the following items . . .

- KG-1 Carbon Remover

- KG-2 Bore Polish

- KG-3 Solvent & Degreaser

- KG-4 Gun Oil

- KG-5 Trigger Lube

- KG-6 Moly Bore Prep

- KG-9 Leather Kote

- KG-10 Dri-Lube

- KG-11 Moly Grease

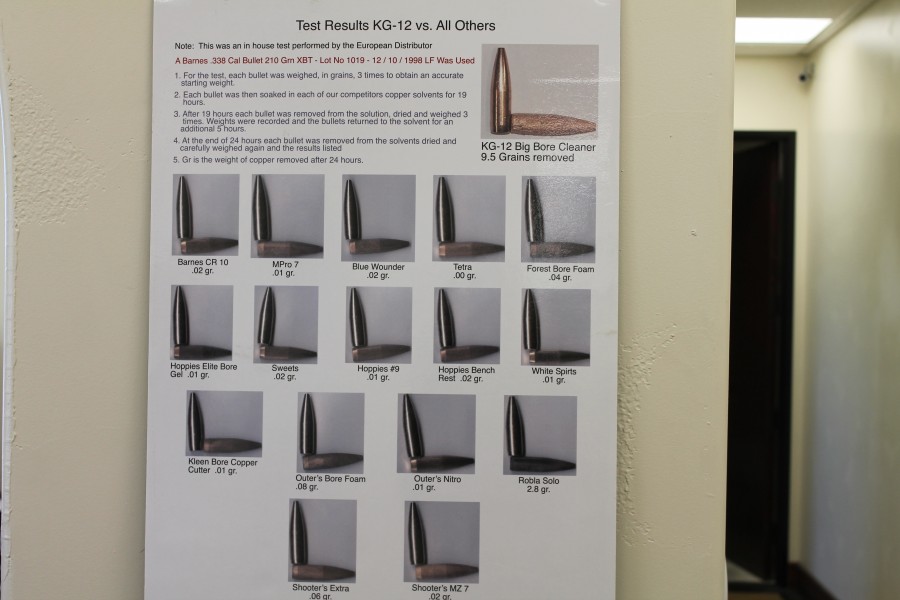

- KG-12 Big Bore Cleaner

- KG-410 Light Weight Penetrating Oil

- KG-SF-112 Carbon & Copper Remover

In addition, KG will be coating two firearms for me. One, a Kimber 1911 with a variety of scuffs and scratches that needs to be brought back to life. The other, my beloved Ruger M77 Mark II will be going in for a full camo makeover in anticipation of the fall hunting season. Hopefully, it doesn’t come back purple with zebra stripes.

As an added bonus, I had to take advantage of the fact that KG’s worldwide headquarters is just a short 45-minute drive from (soon to be) TTAG Central Command in Austin, TX. I met with Joe and his crew to check out their operations and learn a little about their start, success, and production process.

Joe is the do-it-all guy behind the desk as well as the resident mad scientist, tinkerer extraordinaire and hospitality specialist for visiting bloggers. He tells me that while KG’s products are in use at nearly every gun and ammo company in the country, they’ve never really advertised in major publications. Their success has been mainly attributed to word of mouth. Truth be told, I only know about them because I used their cleaning system at Gunwerks in Wyoming.

After chatting for a bit, Joe offered to take me on a tour of the facility. During the tour, he showed me the chem lab where they develop their latest coatings, cleaners and lubricants. He also showed me the custom rig he built to test abrasion resistance. When I asked him why he built a custom testing rig, he told me that nothing to test abrasion resistance mimics a gun clearing a holster, so he had to build one of his own. Next, I spotted a large aquarium. They use it for salt spray testing before their products are sent out for “official” testing.

Over coffee, I asked Joe where he got his PhD in Chemistry. He let out a hearty laugh and told me that he failed high school chemistry, but maintains an extensive black book of contacts at major chemical companies around the world. He’s been doing this for decades and more often than not, he gets to mixing and matching and creates the next new thing at KG.

The staff is top notch, and they take a substance-over-flash approach to innovation, marketing, and production. That’s the kind of thing I love. Spend 10 minutes on Google and you’ll find that KG has a stellar reputation on gun forums for their coatings and cleaning systems. TTAG is going to spend the coming weeks and months vetting the KG portfolio and giving you a one-stop show for those reviews.

Oh, and there’s one more good reason to go to Taylor, TX

How about including a review on the BBQ place too?

Good. Not worth the hype.

How’s about JUST the barbecue?

Or save that for THE TRUTH ABOUT BARBECUE?!

As for the product array: remember when ONE product did it all?

One still does, but how did commerce survive?

Looking forward to the series. Gun reviews are what first brought me to TTAG.

Awful lot of nice stuff to say prior to a product review…

Nice people. I’ve got some seat of the pants experience, but haven’t done a proper test yet.

Not official tester but have been using the KG system and very happy. The oil in my experience lasts after many trips to the range. For at home cleans I prefer a through cleaning.

You guys are moving to the most democratic/liberal part of TX. Ha.

That much closer to the legislative process.

Looking forward to it.

Comments are closed.