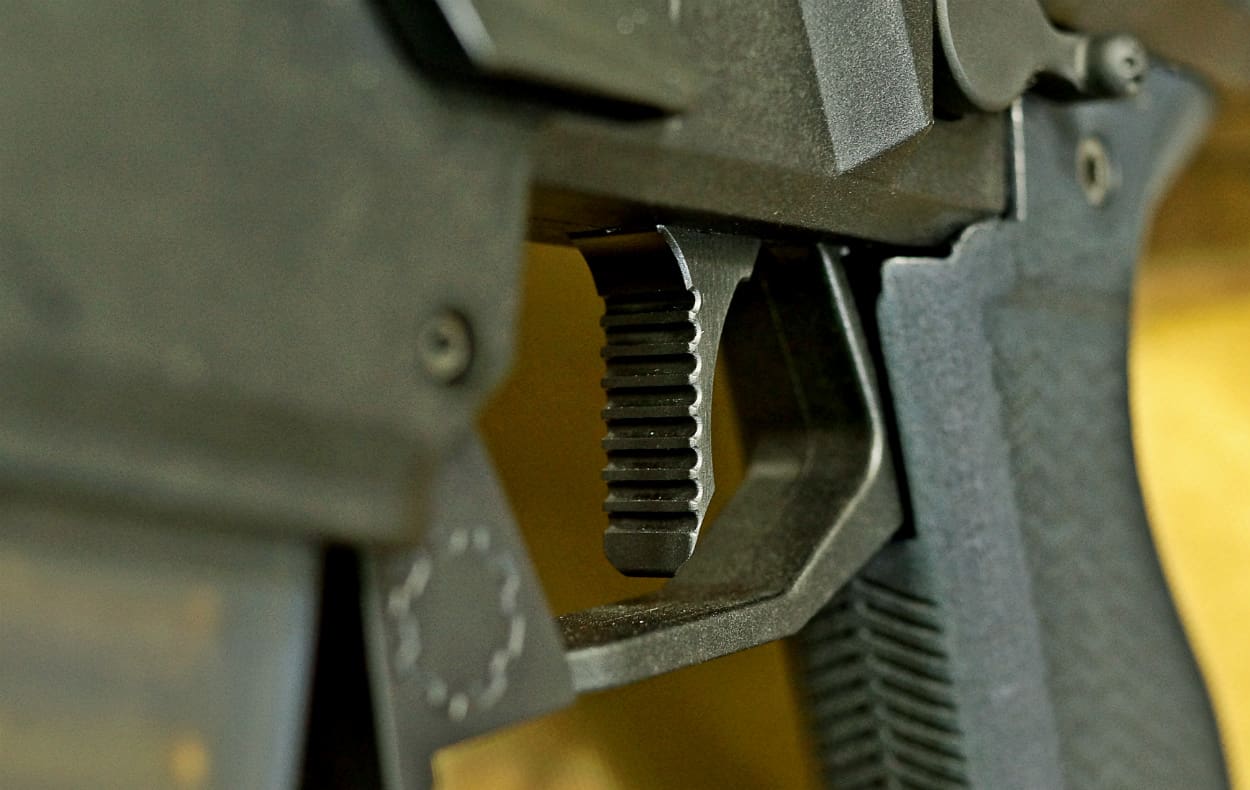

I love me a flat trigger shoe. When I saw this “Stinger” trigger from Nelson Precision Manufacturing — a company rapidly gaining notoriety for its AR.5 bottle opener — on CZ-USA’s Instagram feed, I knew it was going on my Scorpion . . .

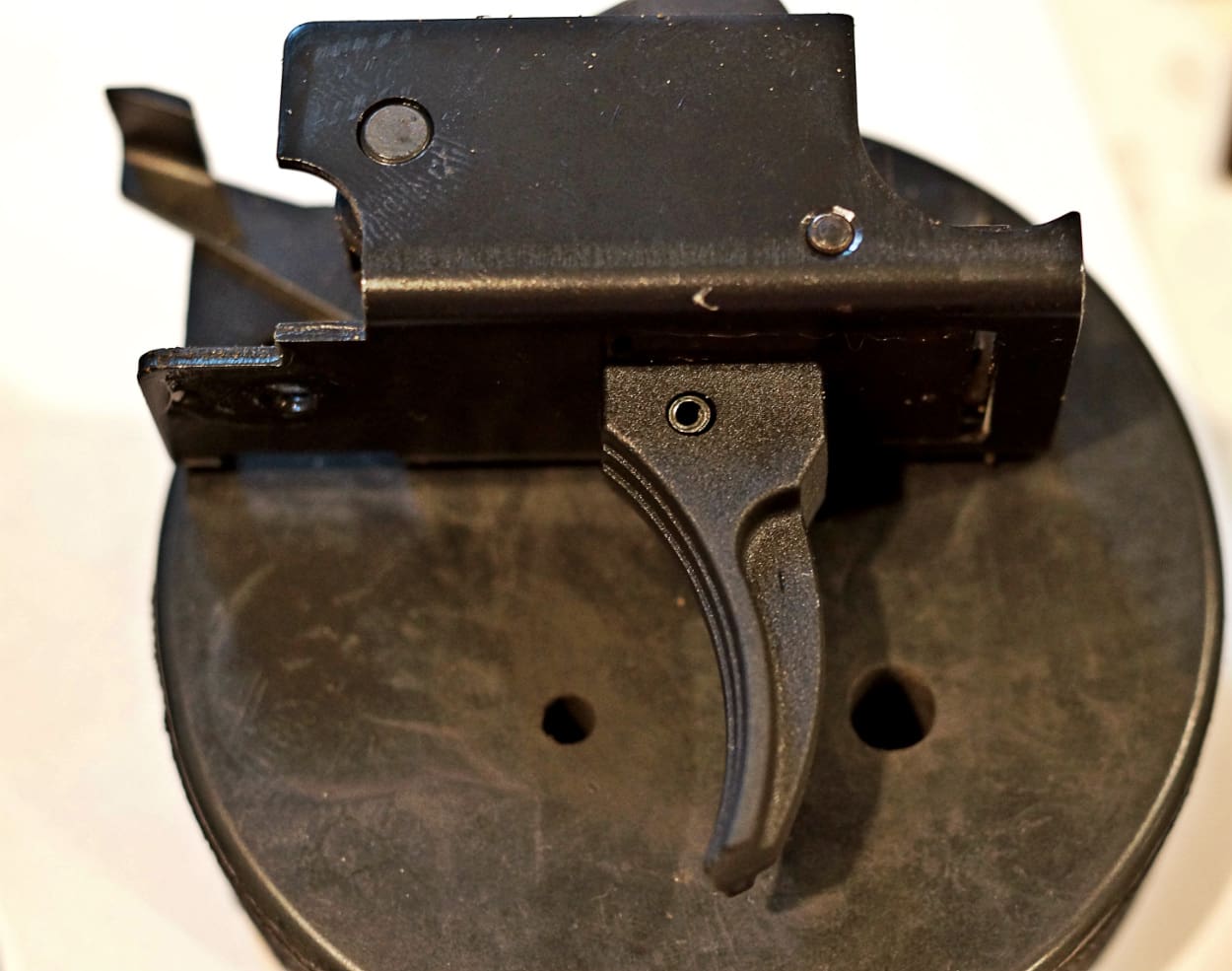

There’s the factory unit. It’s FRP — fiber reinforced plastic, or “polymer” in gun marketing parlance — and has a pleasing curve to it and a vertically-serrated face. Just like the magazine release I replaced, there’s nothing wrong with it. Of course, and again just like that magazine release, this doesn’t mean there’s no room for improvement.

We’re strictly talking about the trigger shoe here — only the part you actually put your finger on. Nothing about the mechanics of the fire control group is changed. Nelson’s Stinger trigger is a very simple swap, replacing the factory unit and reusing the same roll pin to hold it in place. It fit precisely on that little steel bar that protrudes from the bottom of the FCG.

The Nelson piece is machined from 6061 aluminum and is then hard coat anodized. A beveled edge around the roll pin hole made installation of the pin nice and smooth. Fit was spot-on snug. All edges also receive a slight bevel, including the left and right edges of the trigger shoe’s face.

On The Range

I’ve probably said this a zillion times in other articles and in article comments, but I like flat trigger shoes. Something about how it feels on my finger is pleasing to me, and I love the aesthetics of it in most cases — definitely including this one. The horizontal serrations on the front of the Stinger trigger worried me a bit based on photographs, but as it turns out they’re completely comfortable. Less surprisingly, they’re also grippy for confident purchase.

As usual, the feel of metal over polymer is a plus in my book. Basically, the Stinger hits on all of my preferences and it improves the on-the-range experience even if the trigger pull itself isn’t changed. Improve the feel in multiple ways, improve the looks, and you’ve improved the shooting experience.

Specifications (Nelson Precision Manufacturing CZ Scorpion Stinger Trigger):

Material: 6061 aluminum

Finish: Type 3 Hard Coat Anodized

MSRP: $32

Ratings (out of five stars):

Quality * * * * *

No flaws. Fits great. Machining and finish are great.

Ergonomics * * * * *

Nothin’ wrong with the factory unit, but I prefer the flat profile with beveled edges, the feel of the horizontal serrations, and the feel of metal over plastic.

Overall * * * * *

Love it.

I love all of the aftermarket parts coming out for the Scorpion. The Scorp is a fun gun stock… all these little upgrades make it even better. That trigger face looks a little aggressive for me. I want to get the new HB Industries Delta trigger and charging handle. Just out of curiousity have you replaced the factory trigger springs with the HB reduced weight ones?

I’m sorry, but as one of the first guys in line to buy the Scorpion when it came out in the US, I’m actually really disappointed in the majority of aftermarket parts that are coming out and getting undeserved amazing reviews. The trigger looks nice… but hardly $40 nice. And the grips in the images look like they just got spit out of a rapid prototype machine… how does anyone consider that production quality? When are we going to get something actually useful like an improved drop-in trigger pack?

As far as I’m concerned, there’s only been about 2, maybe 3 Scorpion-specific parts worth buying – the 922(r) stock kit, and whatever muzzle device you need to mount a can. The third would be the HB Industries charging handle, but only once you’ve added an optic, and only if you have issues with the original handle.

This trigger’s awesome in every way. It got a good review because it deserves it. Whether it’s worth $32 to any particular person is subjective. There isn’t enough of a market here for me to say whether it’s a good price or a bad price compared to other Scorpion triggers, so price really isn’t factoring into the ratings a whole lot. You can decide what $32 means to you. FWIW, HB Industries’ trigger is $35. All of these U.S.-made triggers do count as a 922(r) part, too.

BTW, if you read the review I wrote for the grips you’ll note that they did not get an ‘amazing’ review and the main gripe was that the laser sintering process creates a part that looks and feels basically like a prototype. They’re perfectly functional, but it’s exactly as you described and that was made clear.

I’d consider replacing the charging handle if somebody comes up with a folding one. I can see the utility in having one that protrudes farther than the factory one does — I’ve scraped my knuckles on the rail or on an optic mount — but only when actually using it. When I’m not pulling on it, I really don’t want it sticking out in the wind. A spring folding unit would be ideal.

I agree that it’s a nice trigger and I suppose if you’re trying to piece-meal your way into 922(r) compliance, it’s a good selling point – didn’t really look at it from that angle.

I’d pay $20 for the equivalent of a trigger shoe (and I’m sure a lot more people would, also), but maybe $30+ matches the volume Nelson is able to produce. Pricing it lower and selling 10x the amount doesn’t help w/o the manufacturing bandwidth…

The way I look at accessories is you need to price based on the target audience. Most Scorpion owners are people that have wanted an MP5 or similar for years, and jumped on the CZ due to the price. Same reason aftermarket car parts for a Porsche cost more than those for a Honda – obviously generalizing here, but Porsche owners have more money to spend…

For what it’s worth, I feel the same way about the HBI trigger (shoe); I only mentioned the charging handle as they’ve got the only extended one I know of, at the moment.

I’ve got mixed feelings on a folding version – I like the idea of a no-snag design, but I’d hate having to dig it away from the receiver with my fingertips. I’m used to grabbing the handle (AK, SCAR, etc.) with the side of my palm, either the flat on the pinkie side, or the web between index and thumb. The left-side rail placement will probably make fingertips a necessity if it folds.

You actually can already piece-meal your way to 922r compliance without buying the CZ-USA compliance kit. There are U.S.-made barrels, muzzle devices, triggers, grips, magazine baseplates, and magazine followers available. Hammer, sear, and disconnector are in the works with a few companies as well. If you use a US-made stock instead of the factory Czech one, you’d only need to swap out 5 of the following parts with US-made ones. If you use the factory stock, you’d need to swap out 6.

(1) Frames, receivers, receiver castings, forgings, or castings.

(2) Barrels.

(3) Mounting blocks (trunnions).

(4) Muzzle attachments.

(5) Bolts.

(6) Trigger housings.

(7) Triggers.

(8) Hammers.

(9) Sears.

(10) Disconnectors.

(11) Pistol grips.

(12) Forearms, handguards.

(13) Magazine bodies.

(14) Followers.

(15) Floor plates.

A friend installed this, seemed to improve his bump fire technique

MAGAZINES! New charging handles, triggers, grips and safeties mean nothing if the magazines crack into pieces in less than six months. I can already hear the fanboys hammering away at their keyboards about how “magazines are consumables”, “you must have abused them” and “they’re only $20, just buy more”. As far as I’m concerned, this gun is the equivalent of a Larue Tactica .308l rifle adapted to only work with Chauchat magazines. Amazing gun, worthless magazines. Sold mine and put the money into my AR, regret buying the scorpion to this day.

While I don’t regret it, I certainly don’t have the enthusiasm towards the Scorpion as I did when I first bought one. There’s a reason it’s cheap when compared to other similar pistol-caliber carbines.

Did you know that if you strip out the tiny nuts embedded in the receiver you need to replace the actual serialized receiver?

Do you know how fun it is to change the serial no. on a pending form 1?

If you take the trigger pack out and strip the non-standard retaining screw inside the trigger guard (you will), did you know it can take 3-6 months to for CZ to get one back in-stock? You can get a similar standard screw that will work in the interim, but due to the unique stepped design of the OEM part, the standard screw will loosen during firing causing the trigger pack to move internally.

I’ve only shot mine about 10-20 times since I bought it, and these are all lessons I’ve learned.

As a simple ‘take it out and shoot it’ gun, the Scorpion shines. Once you start modifying it, disassembling it, etc., you’ll quickly find out how fragile certain parts of the gun are (and how much the guys on the assembly line enjoy thread-locker).

It’s funny that you mention the magazine cracking issue, as it’s one of the few things that keeps running when it breaks. You can lose 50% of the feed lip material and the gun doesn’t even notice.

I was so excited when I saw this article’s headline, then I read:

Nothing about the mechanics of the fire control group is changed.

One of these days my Scorpion will have a non-sucky trigger pull…

Yeah, I’m still excited for a drop-in aftermarket trigger pack. CZ Custom may be the first to get one to market. The had a Scorp with their trigger pack installed at SHOT Show. New hammer, adjustable sear (like 3.5 lb trigger), and trigger.

I wouldn’t expect anything less from Nelson Precision manufacturing! Everything that this company engineers and machines is top notch. The time that went into designing and manufactueing this trigger makes it well worth the money.This trigger is awesome and it looks great on the scorpion! Keep up the good work! I can’t wait to recieve my AR-5 bottle opener.

Comments are closed.