From Ammoland:

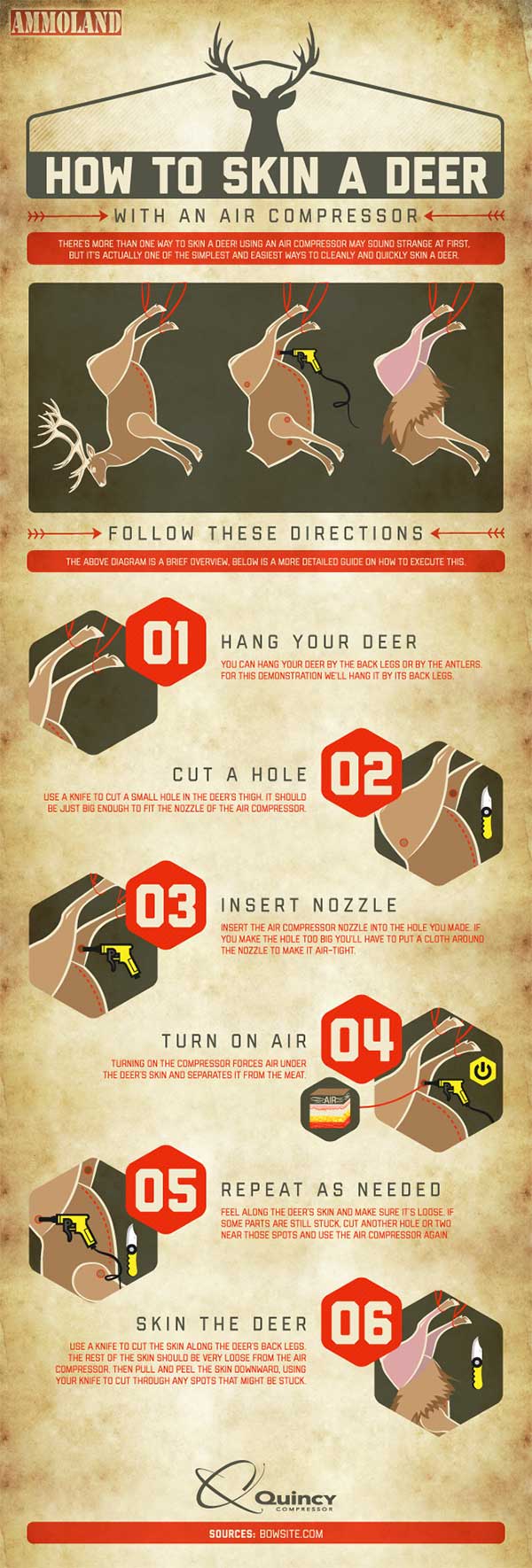

Hang Your Deer

You start out the same way you would normally skin a deer. There are different thoughts about if it’s better to hang the deer head up or head down, but we’ve found that when you’re using an air compressor it doesn’t make a difference. Pick whichever way you’d like or are used to and hang the deer at a level where you can easily reach the whole critter . . .

Cut A Hole

Once your deer is hanging securely, it’s time to make the first cut. Use a knife to cut a small hole in the skin that covers the deer’s thigh. This hole should be just big enough to fit the nozzle of the air compressor. Ideally you want to make it so that no air can get out once you have the nozzle in. If you find that you’ve made the hole too big you can put a piece of cloth or tape around the nozzle so it fits.

Insert Nozzle

Next, simply insert the nozzle from the air compressor into the hole you made in the deer’s thigh. If it doesn’t fit, either make the hole larger or use tape or cloth around the nozzle to make it air tight.

Turn On The Air

Now it’s time for the fun part. Turn on the air compressor and watch as the deer starts to puff up light a balloon! What happens is that the force of the air pushes under the skin and causes it to push itself off of the meat. The air separates the skin cleanly and neatly without causing any meat to go to waste.

Repeat As Needed

Usually this works very well, but every once in a while there will there will be parts that are still stuck. If that happens, simply cut another whole near that spot and repeat the previous steps. After doing this a couple times you’ll have the skin completely separated from the rest of the deer.

Skin The Deer

Last, all you have to do is cut the skin along the deer’s back legs and then start to peel. The skin should be very loose from the air. Start at the top and peel the skin downward. Use a knife to cut through any spots that still might be stuck. Then just like that, you’re done! You’ll have a perfectly skinned dear without any wasted meat. Happy Hunting!

About Quincy Compressor

Quincy Compressor: Manufacturer of world class reciprocating and rotary screw air compressors, vacuum pumps, air dryers and parts. Visit quincycompressor.com.

Just be careful not to get any on ya.

Just be careful not to get any on ya.

Get any what,… air?

🙂

Actually, BLAMMO, be careful not to get any *in* you.

It can *literally* tear you a painful new one…

🙂

While the premise seems sound, I can’t help but feel like this is a trick to make someone blow up a deer in their garage.

I’ve not heard of this before. It does make a bit of sense.

If all goes well, I’ll be trying this on an elk next weekend. That is, if the ghost of the woods allows me to see it.

I’ll see you there

Will be a bit south of Newport, hunting inland towards Siletz and the LOG area.

See, air compressors aren’t just for sex toys.

You can adjust the foam handlebar covers on your beach cruiser the same way

Just like in the Swiss Family Robinson!

Who thinks of these things? 🙂

Is anyone going to fix these runaway JavaScript issue from your advertisers? At times, it makes the site completely useless, and tends to crash browsers. I once watched this website suck up a gigabyte of RAM in less than 30 seconds. This has been going on for several months, and it is driving me away.

A script on this page may be busy, or it may have stopped responding. You can stop the script now, open the script in the debugger, or let the script continue.

Script: https://secure-ds.serving-sys.…urstingScript/SZMKFLVPAIDBR.js:17

Get Ghostery – Extension for Chrome that blocks 99% of ads.

You allow scripts to run on this page? :-O

Aaaaand… Watch the idiots contaminate their meat with oil and other crap out of the air compressor tank.

About the only way I’d do this would be if I had access to a medical-grade or scuba compressor, one that would have clean air coming out of it. The typical construction or mechanical shop compressor your average person has access to ain’t going to have that little feature.

I would strongly recommend people doing this to carefully examine the contents of their compressor tanks, and then ask the question “Would I want to eat that…?”.

“Aaaaand… Watch the idiots contaminate their meat with oil and other crap out of the air compressor tank.”

Bingo.

Compressor oil isn’t nice stuff. The SCUBA tank is an excellent choice for clean air and portability. Just use a new hose and nozzle.

And zero mention in that article on compressed air safety. In a nutshell, treat a compressed air nozzle roughly the same as a gun muzzle at short range, compressed air can *literally* tear you a new one. I’ve seen the pics in yearly OSHA mining safety classes, it ain’t pretty.

That method would be good for mass-processing vermin hogs.

EDIT- should read:

“…treat a compressed air nozzle roughly the same as a gun muzzle at short range…”

TTAG, the edit function fails about 50 percent of the time now, it’s getting WORSE…

That was the first thought I had too, oil contamination – however minimal it may be. I have a deer hanging right now and it’s very tempting to try it. The only way I would consider doing it is with an oil/water separator like for use when spraying automotive paints. The line after the oil/water separator and blow gun would have to be new and free of oil as well. I once knew a butcher who used harborfreight air compressors filled with salt brine for injecting sausages – I don’t know how any health inspector would ever let that fly. I vowed not to eat anything he made after that. Once you have petroleum oil in a compressor head, it will never be close to food grade clean again.

Try to avoid inserting the compressor into existing orifices…

Any practical experience with this you’d like to share?

🙂

I bet this works with people too – and just in time for the holidays!

Seems like a prank, maybe one of the hunters should try it on themselves first and see if it works.

If this don’t say Redneck, nothing does.

…not as redneck as swapping “don’t” for “doesn’t”.

Exactly. Wondered if you’d catch that. You pass the grammar police exam.

Ever watch Swamp People?

This is how Bruce Mitchell skins alligators.

I saw Iraqis skin goats this way.

It’s also SOP for separating the skin off a Peking Duck.

Next: how to gut your deer with a pressure washer.

We need Tim Allen to do a how-to video on this.

“What this needs is a little more power.”

a) I wouldn’t use my normal compressor for this without an oil trap/filter on the line. There are compressors out there that use no oil, or have filtration on them.

b) some kill floors do something very much like this to jerk the hide off cattle when they’re processing them.

c) this isn’t a new technique – it’s been around since, oh, the 50’s or so.

I’d try this is I had access to clean air (as mentioned in previous comments), like SCUBA equipment. However I skin carefully as I keep my hides (rugs and buckskins!), so I might only be able to do this part-way as I’d only make new holes in parts that won’t leave me with another hole in my hide. But still, this might reduce the amount of peeling I have to do.

Meh, a golf ball, knife, rope, and a trailer hitch. Skinning made easy, and contaminant free.

This works! We’ve been selling Air Skinner kits, which are made for just this purpose, for 15 years. Works on deer and other game animals, as well as big game and predators. Also works really well on frozen deer.

Comments are closed.