New from Bergara for 2021 is the BMR, or Bergara Micro Rimfire. It’s a scaled-down version of their B14R, which is a rimfire that fills the standard short action footprint (fits in Remington 700 stocks, etc…full review on the B14R Carbon coming soon!). With a micro-sized, but real steel action the BMR is smaller, lighter, and less expensive than the B14R but it’s still an absolute tack driver available in .22 LR, .22 WMR, and .17 HMR

In the video above I point out some of the primary features of the BMR such as the cute little 5- and 10-round magazines that are included with it and the fact that it’ll accept any Remington 700 trigger. Then Dan giggles.

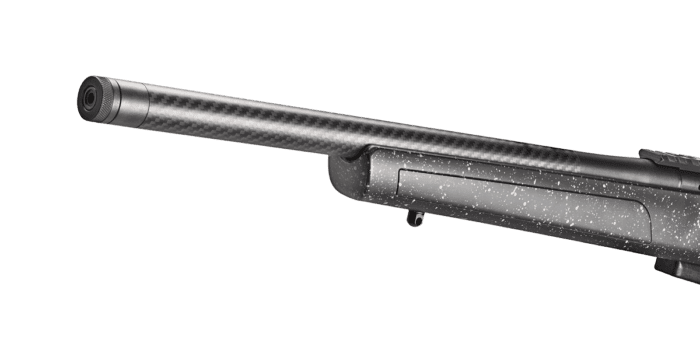

MSRP with a Bergara steel barrel is $565 and with the carbon fiber barrel seen above it’s $659.

See? So cute. It’s a little baby AICS magazine.

Threaded?

Yes

I am always amazed whenever I think about how manufacturers are able to make a straight .22-inch diameter hole that is 16 inches long into a piece of steel (rifle barrel).

For anyone who has ever spent any time drilling holes in steel, small diameter drill bits can easily flex (bend) when you are drilling and cause a hole to “wander” (not be absolutely straight) into the material.

I imagine that barrel manufacturers account for that weakness of small diameter drill bits in several ways:

First, you would start with a short drill bit (maybe only 3/4-inch long) which basically cannot flex to start your hole straight.

Second, once you have that starter hole, that hole and the barrel would then act as a stiff sleeve which would prevent progressively longer bits from flexing while drilling. That means you probably have to change bits several times when drilling a 16-inch long barrel.

Third, after you finish drilling the barrel, you have to ream the bore with progressively larger and/or longer reamers to ensure that your hole stays straight.

I can picture the process being somewhat tedious. Nevertheless, if I had a mill and lathe suitable for that process, I would love to make a barrel.

There’s a special drill bit known as a ‘deep drill’.

Dyspeptic can explain better, it’s designed in some way to self-center itself as it drills into the metal…

LOL, barrels are not made by drilling with a drill bit!

There are several different ways of making barrels and adding the rifling, but none of them involve drilling with a drill bit. For example, Ruger’s barrels are cold-hammer forged — no drilling is involved. Other manufacturers use button-rifling. None use drilling.

That’s weird. So all the company’s with videos showing how they drill the hole into gun barrels are lying to us? It’s a conspiracy! Thanks for letting us in on their evil plans. A peek behind the curtain so to speak.

That’s not accurate, NJ. With the exception of hammer forging (and wire EDM, which one company was doing for rifle barrels but they closed and I’m not sure anyone else is doing it right now), the bores are, in fact, drilled. In your example of button rifling, that’s just how the rifling is created (a “button” is pulled or pushed through the smooth bore, which has already been drilled to the land diameter, and it presses the grooves into the steel). There’s also cut rifling and other methods, but they all create the rifling inside of an already-drilled bore.

The typical bore cutter only cuts at its front face and usually there’s just one “tooth,” unlike a typical drill bit with two or more cutting surfaces at the tip plus cutting ability along the sides. The bore cutter will have a hollow bore of its own for coolant that’s pumped through it and will have smooth sides that are bore diameter except for a channel for clearing chips and coolant out the back. By maintaining a snug fit inside the bore along the entire length of the cutter, the cutter doesn’t wander even if it’s way deep into a long barrel blank.

Also, typically the cutter is held stationary and the barrel blank is what’s spun on the lathe. It’s a much larger diameter and much stiffer so it’s the better, more stable thing to spin.

Anyway, yes, the bore in a barrel is almost always drilled with the exception of a forged barrel where it’s drilled oversized and then hammered around a mandrel that’s like a positive model of the inside of the rifled bore that you want to make. Sometimes even the chamber can be hammer forged in.

BTW bores usually DO wander a little. This can be corrected after the blank is drilled by precisely bending the blank as needed to straighten the bore, but in most cases it really just doesn’t much matter. If every barrel was perfectly straight you wouldn’t really need scope adjustments. But every barrel tends to be a bit of a butterfly, even if only to the smallest degree, and if it happens to curve the littlest bit in any direction that’s what sighting in your gun is for. Move a scope between two examples of the exact same rifle and one might hit two inches higher and a quarter inch left(er) at 100 yards than the other because neither barrel is perfectly straight. But once you dial the scope in you’re aligned with that barrel and everything’s gravy for most purposes. Another way to think of it is if you had a gun where the barrel didn’t index/time but slid into the receiver and therefore could be installed without any “top” or rotational orientation, it would be the rare barrel indeed where POI didn’t walk as you rotated the barrel. Bores are not often perfectly straight and they really don’t have to be. Real close, sure, but rarely perfect.

Perhaps you and New Jersey are a good fit.

The best barrels are made by drilling, with a single-edge gun drill bit, but it isn’t a bit that looks like the twist drills you buy at a hardware store.

Deep hole drilling, aka “gun drilling” is a niche of the machining world that is part technology, part art, part witchcraft. It takes some skill and attention to detail to drill a deep hole (“deep” being > 5 diameters) fairly straight in steel.

Gun drills often have only one cutting edge on them, and then they have a straight “V” groove running the length of the drill. There is a hole in the face of the drill, just behind the cutting edge, where lubricant comes out of the drill to flush chips up the “V” groove. The lube is pumped down the length of the gun drill at hundreds to thousands of PSI to flush the chips away from the cutting face and up and out of the hole.

Gun drilling is more difficult the smaller the diameter hole you want. eg, .17 caliber barrels need higher RPM’s on the operation, and much higher lube pressures, than a larger (eg) .45 caliber hole. The feed advance per turn is also much lower than for a large barrel.

The best barrel makers (Krieger, Bartline, etc) drill their holes under-size for the eventual bore size, and then they ream them to size to straighten small variations in the drill path and to give a much better finish. Then the grooves are cut on a sine-bar rifling machine with a single-point cutter.

Drilled barrel bores is still very much a thing. The benchrest competition community runs on drilled/reamed/single point cut rifled barrels. This is the technique that puts the minimum amount of stress into a rifle barrel.

Was getting a bit concerned, not having seen you posting here in a long while.

Those who actually know what they are talking about here is getting rare… 🙂

Will this gunm be legal under the new BATFE guidelines?

It does meet the .22 caliber requirements, however its brother has B14 in its name. There’s a couple of rifles that have 14 namesakes and they’re on the to be bannit list.

I certainly do not want to be a lawbreaker.

Please make it in lefty!

Turn the rifle upside down, there you go.

They do!

How was its accuracy/repeatability?

I’ll bet the most common “pet” name owners give to their Bergara rifles is Sofia.

Is it clone action?

Try the mags that i used for a year https://raeind.com/

我们的留学生代写团队是公司业务存在和发展的核心基础。突出的是,我们的论文作者在澳大利亚大学接受过高质量的教育,有丰富的论文写作经验,热爱论文写作工作。我们对作家和写作老师的严格要求使我们能够满足不同学科和不同类型论文的写作需求。每个作家都至少有学士学位和留学经历。我们的专家写作团队成员均具有硕士以上学历,全职和兼职从事写作和论文创作。我们知道,只有高质量的写作专家才能为您提供高质量的写作服务。我们竭诚为在澳留学生提供高质量的论文写作服务。https://www.mingxinwrite.com

well.

https://lunwen.littlefairyessay.com/yingguodaixiewz/

That’s interesting

It’s worth thinking about again

It’s not impossible, it just feels like there’s a better way to do it

Comment

like it very much.

People who don’t spend time studying abroad anyway shouldn’t realize the sheer pressure of studying abroad. Many international students go to bed at 3 or 4 am and get up at 6 or 7 am, which is a common practice. Behind the life of studying abroad, there are countless days and nights of hard work, enough to make the overload of reading people overwhelmed, mountains of essays and papers.

Especially business or other liberal arts majors, whether undergraduate or master, homework is basically thousands of words of paper. Moreover, each Essay accounts for a large proportion of the score, which will eventually affect the total score.

Inspired from the tv series Yellowstone, this Kelly Reilly Blue Coat is poncho-style outerwear. Kelly Reilly portrayed the role of Beth Dutton, daughter of John Dutton in the series.

If you love to wear action movies and games outfits so must check the top 5 superb Cosplay Jackets which gives you a killer and stunning look on this cosplay festival.

very good article. love it very much

beautiful wording and analysis choice

I ram in love with it

great post!

Comments are closed.