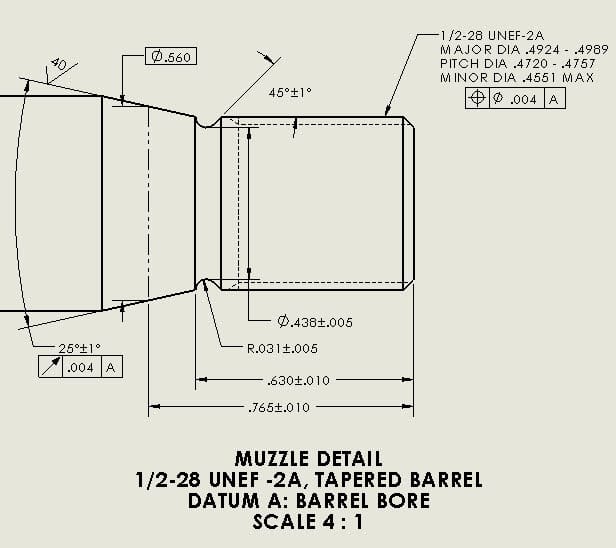

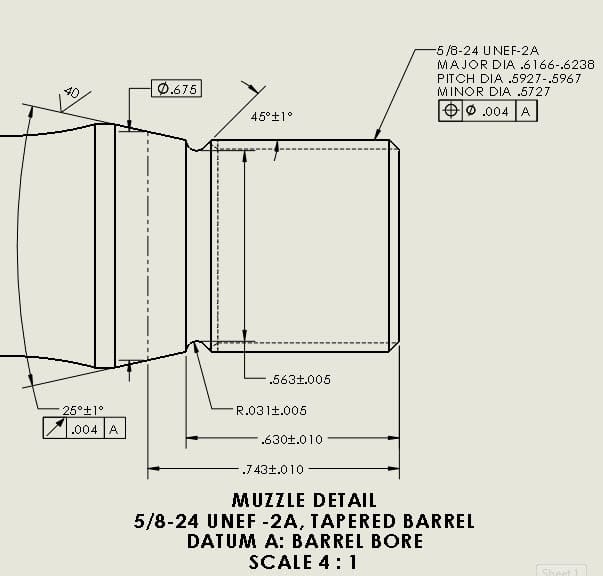

SIG SAUER’s new line of silencers is nifty for many reasons, but one of the main reasons is that they are all about improving the way silencers and firearms interconnect. The typical way a thread-on silencer interfaces with a firearm is through a 90 degree shoulder at the end of the threads, which is okay but doesn’t always keep the silencer tightly locked onto the muzzle. SIG SAUER is trying to fix this by manufacturing their silencers and rifles with a radiused shoulder — increased surface area increases the friction between the parts, and keeps silencers from un-screwing mid firefight. And now they are releasing those technical drawings publicly.

For those who want to cut and thread your existing firearm to work with SIG SAUER’s cans, or for companies who want to allow their barrels to operate with the new line of silencers, these drawings are free to use. Enjoy!

So kind of what OPS Inc. has been doing all along?

Exactly.

Thunderbeast also does this on their CB muzzlebrake line. A conical shoulder locks solidly into the rear edge of the suppressor. It cinches down extremely tight without having to handcrank it too hard.

More like what the rotating equipment industry has been doing for 100 years.

Skippy the Gunsmith threading barrels on his old Monarch 10EE engine lathe is going to curse a lot at having to cut that taper. Easy as pie on a basic CNC lathe though.

Time for old gunsmiths to step it up!

25 degree taper across just over an inch – seems doable on just about any old manual lathe I own from a 12″ Atlas to a 13″ Southbend.

Those old guys will do just fine IMO.

Yeah, I guess no one could do machining before CNC was invented. LOL

Pffft.

You set the compound with a sine bar. Short tapers like that are no problem.

Wouldn’t even need to use the compound, that taper’s what, a quarter inch long? Make yourself an HSS form tool and plunge cut the whole thing in one go, as an added bonus you could cut that .031 radius in the same op with a little careful grinding.

My limited experience with such tools has resulted in chatter-a-plenty.

And to get that form tool really correct, you’d need a T&C grinder.

The chatter can be dealt with, I’ve used form tools with longer cutting edges than that with quite acceptable results.

As for grinding that tool right, it can be done with a standard bench grinder, but it takes practice and a steady hand.

For those confused about sine bars. I had to watch these videos to understand.

https://www.youtube.com/watch?v=ojjdRRXjK68

Meh, set a stupid sin bar on the compound… every time you want to cut this dingus. PITA – at least it was on my old Yam with a sticky compound that was a nightmare. Perhaps my views here are totally colored by what a nightmare that damn Yam was. Shoulda bought a Mori.

Someone never learned to use their machine to the fullest. I could do all of that on a manual lathe easily, and I only just started learning a few months ago.

If you need a cnc to do this you need to find another line of work. I watch machinists mfg massive compressor and turbine shafts all day long on manual lathes. This is a simple taper with incredibly loose tolerances and a radius. You dont even need to fit this taper to gauge and check for blue contact. No grinding necessary. CNCs are not for simple rookie stuff like this.

So its sort of like a Victaulic groove but for suppressors

Cool that they shared it, though. And smart on their part. They can sell more cans if there are more barrels out there that will work with them. Not that it would’ve been difficult to figure out without the drawings, but still. Some companies come up with cool ideas and refuse make them proprietary. Nice to see a company that seems to be interested in furthering the entire industry, even if part of their reason for sharing was done to help their bottom line.

Every silencer manufacturer freely gives out their threading charts, this isn’t something new.

http://www.advanced-armament.com/assets/images/pdf/manuals/ThreadGuideREV_01-040513.PDF

https://thunderbeastarms.com/tech/thread-specifications

Cue the threaded barrel to sig mount adapters on eBay in 3…2…1…..

That adapter idea needs to happen, and sooner rather than later.

The way the suppressor mount sits on a square shouldered, threaded barrel sucks…and what’s worse is Sig customer service is okay with it. Mine screws on only 2 threads on 2 different rifles. They recommended torquing it to spec and rolling with it. No way the last 2 threads on my precision rifle are getting torqued to full thread engagement spec, then hanging a can off them.

Not a big fan of having to pull my barrels to be tapered and the cost & wait time associated with that. A warning or notice in the product description would have been nice…of course, that would assume that Sig thought there was a problem in the first place.

To be honest, with this kind of design / application philosophy and customer service experience, I would buy a Thunderbeast if I had to do it over again. Sig has not been very helpful or gracious for a newcomer with very little market share. I’d think they would do what they could to ensure happy early adopters.

Glad to know the “new AAC” is doing just fine.

Glad everyone is going to be using engineering drawings with no providence.

Most barrels can use the existing threads (good news for folks with 16″ barrels), you just need to cut the shoulder into the specified taper and go. Pretty simple conversion.

Holy s**t! A silencer company putting their thread specs up, for FREE? Call Guinness!

#TTAGslobbersalloverSIGagainandagain

…ugh, if I had a dollar every time my silencer came loose during a damn firefight…

😉

Duh, it’s like a Morris Taper. I’ve been using Tapered Pipe Threads on my Solvent Traps for 2 years now… Not just a tapered engagement surface, but the whole thread is tapered. Pipe Threads already exist, no need to re-invent the wheel or get fancy just for the sake of being fancy…

Morse taper.

I have been wondering if my own method for doing this is truly effective. My results in the past haven’t been altogether satisfying. For this reason, I really appreciate your helpful article about solvent traps. Thank you for the professional advice and information on how to use a silencer like this. I will keep this in mind for when I do this next, thank you!