This has been the year of drop safety issues. First the SIG SAUER P320 turned out to discharge when dropped. Now the Honor Defense Honor Guard is vulnerable to the same problem. Which raises the question: why didn’t these companies find and fix this before the pistols went out the door? And what can we do to solve it in the future?

In response to The Firearm Rack’s and our articles, Honor Defense issued a statement revealing the mindset of manufacturers that illustrates the central problem:

We believe that Honor Defense makes the best single stack 9mm pistols. We have tested internally and submitted the firearms for testing by independent labs.

The product exceeded all industry abusive handling tests and proven to be more accurate than other similar sized firearms.

There’s that term — “testing” — that’s what’s causing the kerfuffle.

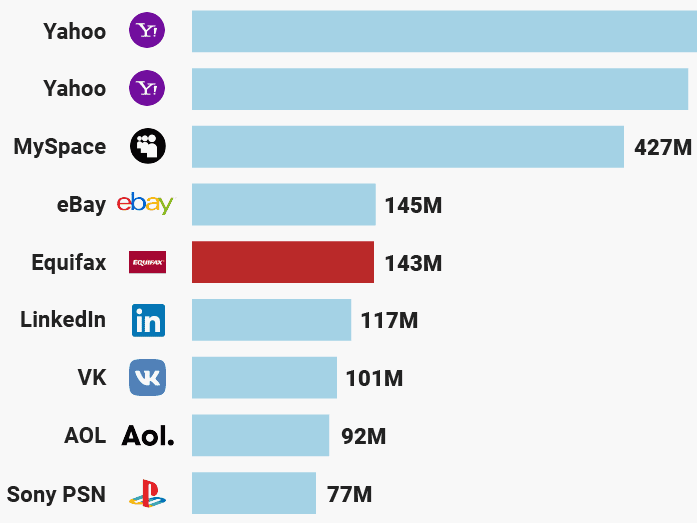

I see this every day in my day job as an IT security engineer. Both Honor Defense and SIG SAUER have fallen victim to the same mindset that causes credit score companies to leak our personal data and allows entire healthcare systems to fall victim to simple cyber attacks. And there’s no way that is going to change any time soon.

In the IT world there are a set of standards that are either enforced by the industry (PCI/DSS) or by the government (HIPAA, GDPR, etc). They set a baseline for security practices which everyone needs to meet if they want to continue operating.

In theory, these standards would simply be the validation of an existing robust security program, one which would properly secure all aspects of the business. In practice companies build up barely enough of a security team to squeak by on the specific compliance requirements and ignore everything else.

It simply costs too much money to properly secure their networks. They’d much rather pay the much smaller bill stemming from the effects of a potential breach than pay for good security up front.

Gun companies are the same way. Many buyers consider their firearm choice a matter of life or death. At the end of the day, it’s still a business. The companies need to make a product that functions to the required specifications while still being inexpensive enough to generate a profit.

There isn’t a legally-mandated standard for firearms design. In some states (e.g., California and Massachusetts), a firearm must pass safety testing protocols before it can be sold to the general public. Aside from that, firearms manufacturers’ products need only face the same body of product liability law that everyone else has to follow.

The industry has created a series of voluntary technical standards, such as SAAMI for ammunition dimensions and the NIJ for a whole host of other things. And manufacturers competing for military and law enforcement contracts must satisfy standards listed in their contracts — which don’t apply to firearms designed specifically for the civilian market.

Even if manufacturers comply with the voluntary standards when they build their guns, that doesn’t mean their products are 100 percent safe. As Equifax learned, PCI compliance isn’t the same thing as being secure.

Meeting a standard only applies to the specific metrics being tested. The SIG SAUER P320 and Honor Defense Honor Guard are 100 percent drop safe –when dropped according to California’s standards. When dropped in a way not tested by the standard, they failed.

How do we fix this?

One approach: build in a mechanism for continuous improvement. That’s what the PCI/DSS standard does. It dictates that certain ongoing improvement projects must be in constant operation to maintain compliance.

With the firearms industry the standards could be written to require a response to identified vulnerabilities, such as this drop safe issue. Should the companies be forced to make a compulsory recall, instead of a voluntary one? That’s only possible if there’s a law requiring it. At the moment there isn’t.

Right now, consumers have all the power. Aside from suing companies that put our lives at risk, we use our wallets to decide which companies are taking appropriate steps to design, build, sell and if necessary modify firearms to ensure our safety. And which ones still need to see the light.

As long as the cheapest handgun in its class is the one to buy, people will be finding fault with said firearm. You should never drop a firearm, you should be aware of what type of safeties and what they actually do to make the gun safe are. Safeties are a good thing. If you want to remove it, it is your firearm. Just do not sell that weapon without notifying what was done to it.

“You should never drop a firearm”…Hahahahahaha. You should never drop a phone, or your beer, but shit happens, doesn’t it. If a handgun isn’t drop-safe, its simply not safe.

Some of the greatest firearms in history (the famous or infamous) Kalashnikov and Stoners prototypes passed stringent testing and standards and subsequent generations of these rifles addressed both vulnerabilities as well as flaws. A gun manufacturer does not have foresight but also when a vulnerability is identified they must address it. Like the article says with IT, (CISCO systems) notified windows outlook had a flaw, and windows didn’t address this flaw and winX launch date saw a rise in ransomware.

My low cost, cheap, affordable, reliable Hi Point 45 has no problems. May be the “big boys” think they can get away with cutting corners??? In know some Remington shot guns have been discharging even when the safety was on.

I do have other expensive guns. But I like any product that is well made and shoots when I need it to.

No one needs to spend $$$$$$$$$ to get a reliable firearm.

I have no idea what point you’re trying to make. What do you mean by ‘cheapest in its class’? The Sig and Honor Defense are not even close to the cheapest striker-fired handguns around. Cheaper guns manage not to go off when dropped. And your silly “don’t drop your gun” argument could be used to negate the need for any and all safeties altogether. Heck, forget about guns- why do we need airbags and seatbelts on cars, anyway? Don’t crash!

I agree with Hannibal.

One evening while engaged in a foot chase, my holster broke after hitting a vehicle and my G23 fell out, causing the firearm to land on its rear plate, resulting in no discharge, dented slide cover, and only the rear sight (Trijicon) being pushed about half way out after the bounce. I paid $390 for the brand new G23 (can’t get any new SIG for that price), $60 for the holster. Guess which one was immediately discarded.

For you idiot Glock haters….the holster was tossed.

Isn’t that how the 320 issues came to light? A cop dropped his HOLSTERED duty weapon and it fired a round into his leg?

It is read you are correct. A Stamford officer dropped his gun while in holster in a SWAT team parking area. I don’t understand what that means; maybe his holster was not attached to his belt and was dropped or maybe he dropped his entire belt.

I see people trashing hi point saying it a “cheap” gun. Really????

Does it hurt holding the powerful accountable???

SW Engineer here, so I agree with the “testing is only as good as the test cases” sentiment expressed above.

From a practical standpoint, with firearms, “drop safe” really means “doesn’t fire unless the trigger is pulled”; can we agree on that? I’m going to guess yes we can.

Now it becomes how can we make the gun fire? Simple statement is “firing pin hits the primer with enough force to detontate primer and start the chain reaction”.

Now we need test cases that cause the firing pin to hit the primer with enough force.

A good argument can be made that hitting the slide with a mallet is not standard practice, but it is a substitute for say hitting the slide into a door frame.

A comprehensive test suite is time and money; does every single pistol on a line get tested or are samples pulled at random? If at random, how many?

I am not saying it’s not worth it or it should not be done, but every time I thing I’ve made test cases to cover all the idiots, I run into a bigger idiot. Thats why soda machines have labels saying “could cause death if you tip it over onto yourself”.

I don’t have an answer other than vote with your wallet.

Wow. Smith Wesson QC has been garbage for the last several years. Definitely a company I now avoid.

《《《Complete opposite experience.

Huh. I read “SW” to be software.

I would read “S&W” to be Smith and Wesson.

I wonder which is right?

I’m placing my bet on software.

“From a practical standpoint, with firearms, “drop safe” really means “doesn’t fire unless the trigger is pulled”; can we agree on that? I’m going to guess yes we can.”

And I’m going to guess no, we can’t.

I have seen, with my own eyes, an SKS fire (it actually doubled) when the bolt was allowed to go forward after a reload. Trigger was definitely not pulled. The bolt was so gunked up the firing pin was stuck in the forward position.

If you had said, “From a practical standpoint, with firearms, “drop safe” really means “doesn’t fire if the gun is dropped””, I would agree with you.

Slam fire (the malfunction you described in the SKS) is a wholly unrelated issue to “drop safety”. “Drop safe” is indeed a misnomer though; it should be referred to as “impact safe”, as in “no impact insufficient to critically damage the mechanism of the gun itself (such as a 4 to 5 foot drop) will cause it to discharge.”

“doesn’t fire unless the trigger is pulled”

A slamfire definitely counts.

I was pointing out the problem with definitions; you have to be careful how you word them.

Retired Aerospace Engineer/Government Contractor. Within our industry, there are standards for everything from a toothpick to the space station. I recently contacted the ISO Commettee to see if world-wide there were any International Standards on firearms.

This was their response: “We don’t have any standards specific to firearms or munitions. The only related standards we have are those related to acoustics with regards to noise from shooting ranges, which you will find listed via the following link:

https://www.iso.org/ics/95.020/x/p/1/u/0/w/0/d/0

When we manufactured components for an M16 or other weapons, our quality requirements are more stringent than the original OEMs requirements. But yet, the acceptance standards are basically common industrial manufacturing standards. IE ASTM, ISO or AMS and primarily pertant to materials and processing of the component.

I find it odd that we have an abundance of standards for kids toys, but “zero” for firearms.

Somebody might have gotten hurt if they tested them at the factory?

A student if firearms history would at this point remind us of the ancient European tradition of proof testing. Go take a look at any European firearms you own and you’ll see a stamped marking on the barrel or breech that looks like a heraldric device or family crest of some sort… and that’s exactly what it is, in a way.

That is called a Proof Mark. It means that particular gun or barrel was tested with a double-or-more strength cartridge and survived; so theoretically it should be able to handle any standard cartridge you load into it.

It means nothing at all about the SAFETY of the gun’s design… and that is the issue at hand here. But the process would be similar: subject a gun to an unusual degree of stress (drop it, throw it, insult it) and give it a stamp if it passes.

🤠

Well with the trend towards cheap striker fired polymer pistols they won’t be perfect. I’m interested in the brand new cheap version of the LC9s-EC9s. Is it “less safe”? Dunno’. It appears mechanically identical to the original. Obviously cost is not a prime indicator of QC…and arrogance won’t keep you in business.

With all the copying in the firearms industry you’d think companies would learn from the ones who’ve gotten it right. Probably too much to ask.

Does anyone have a quick, off the cuff, numeric total of all the potential points of impact of a firearm in a sphere surrounding the firearm? Are there hundreds? Thousands? Millions? (I have no idea)

Do all those potential points of contact need to be “drop tested”?

Number of points on a sphere is zero. Number of vectors at which you can approach a point in 3d space is infinite. A gun being a 3d object makes that approaching infinite points from imfinite directions. So infinite-infinite, that’s your answer.

Damn, you smart!!

S M R T

I mean…

S M A R T

If your considering an external force applied to the firing pin as mentioned above, and not a different failure resulting in a hammer fall or what have you, then I would say no. The most force is going to be transferred when applied tangent to the firing pin’s axis. Any other direction will result in less force transfer in the direction of motion. Therefore, if dropping it on it’s end doesn’t push the firing pin hard enough, dropping it any other way wont either.

As a guy with years more software experience than many here, in systems from small to huge, and now with some perspective on firearm and firearms design… let me just say this about that:

1. Using software industry practices as any sort of model for safety design and/or testing in any tangible (ie, physical) product is… misguided. If we designed tangible (physically dangerous) systems the way that software is executed, we would see results of: planes falling out of the sky, bridges collapsing, and cars that come off the showroom floor that blow up into a flaming wreck before they come to their first stop sign.

The term “software engineer” is an oxymoron, at best. i’ve done software, I’ve done hardware design, I’ve worked with MechE’s on some mechanical systems, I’ve seen how real engineering is done, and I’m here to state for the record that there’s precious little “engineering” in modern software development.

The US software industry has a shameful record on quality, reliability and security. If we used the software industry’s practices in areas where real engineering happens, modern society would literally collapse into a flaming heap by the end of the week.

2. There is little opportunity to “test” quality into a firearm, the way quality is “tested into” software in current practice. Tangible, mechanical design either works or it doesn’t; components inside a firearm have to obey the laws of Newtonian physics, unlike the internals of a software system. In several of these pistol designs, there are obviously problems of design. Fixing their issues after the gun has shipped is expensive, and ruinous to a gunmaker’s reputation.

3. The way European gun companies have to deal with these situations is that they have national proof houses, who at the least test firearms components (such as barrels & chambers) with overpressure loads, and then safety test completed firearms designs. We (the US) have no national proof house. The closest thing we have is HP White Labs, who will conduct destructive and non-destructive testing on firearms on a contract/T&M basis. We could develop a national testing house, but we all know the goddamn politicians and lawyers (but I repeat myself) would use a national testing house as a weapon against us. So here we are… doing gun design historically in the US by “over-building” guns to be more redundant in several dimensions.

4. I’m sure there are many people here who are tired of reading my rants about how the American gun buyer is being conned into buying crap product. There’s a cohort of people for whom the price can never bee “too low,” so long as they get something that approaches acceptability; product excellence is simply never a priority for these people. Sadly, they’re the majority of gun buyers now, and that’s why we can’t have a gun maker like the pre-WWII Winchester, who would ship you a catalog of very nice options, features, embellishments, etc that you could ask them to put on your gun at the factory. Your gun would arrive several months later at your local Winchester dealer, and you’d have a semi-custom gun, very competently done. Several companies had a business model like this.

Well, all of that was done away with by mass marketing in the US – the same clowns who have been trying to convince you that McDonald’s is fine cuisine are trying to convince you that a plastic pistol with stamped sheet metal lockwork is “quality.”. The result is ultimately what you see here – the realities of trying to hit a price point crowd out any budget for serious design, destructive/non-destructive testing, serious proofing of components, etc. People have howled when I stated that shipping a quality pump shotgun would cost about $1K each, that there is no way to re-introduce the Colt Python for under $2500, etc. You want to delude yourselves that your currency is still worth something, when the Federal Reserve has a stated goal (up front, in public, no apologies made or expected) of making your currency worth only half of what it is currently worth in 36 years, give or take, and then you want to take that currency and buy a firearm of the same quality you’ve seen available in the past for the same “under $X” price point.

Well, that’s not going to work. You can rant, rave and fume at me, the messenger, but I know I’m right – because y’all are happy to pay 10X what we used to pay for a pickup, 10X+ for a house as they cost when I was knee-high to a stump (mostly because you can get credit from a banker to buy these things), but you’re going to bitch about gun prices going up as much or more, because we now have more regulation in, and of, the gun industry than we had 50+ years ago.

The gun companies listen to those who claim they’ll never pay more than $X (where X is a small number) and keep the price down, but then the customers bitch about the results of the shortcuts necessary to hit your price points. There aren’t many people out there who do gun design competently, there aren’t any academic courses in gun design, and just testing guns in FEA/CFD packages gets you only so far. Sooner or later, reality requires powder to be burned and guns be tested in the real world. Well, if you’re not willing to pay for the testing to be done in-house in a gun company, guess what? You’re going to be doing the testing with your hands, your ammo and your face behind the gun.

You can’t eat your cake and still have it too.

On the whole inflation point, I found a bunch of my grandfather’s reloading equipment and supplies in the original packaging with the prices still on them. It was all insanely cheap.

Now I couldn’t ask him when he bought the stuff because he died well before I was born. I had to guess what the latest point in time he could have bought the stuff was. Adjusted for inflation, he paid about the same as, if not more than because I guessed too late, what were the current prices when I checked.

“Adjusted for inflation, he paid about the same as, if not more than because I guessed too late, what were the current prices when I checked.”

There is truth in that, to an extent.

I recall an article I read back in the early 1990s about someone bitching about the cost of a new light piston single-engine aircraft, the ‘ole reliable, Cessna 172.

It seems a bit of research showed the cost of the new Cessna closely tracked the price of a new Rolls-Royce automobile, over the 5-plus decades.

Both vehicles are *insanely* labor-intensive to manufacture. One, because people wanted (then, and now) near perfection in the fit and finish, the other because human life was, and still is, literally at stake…

Maybe you worked with crappy software engineers. Some of us produce systems that are more reliable than any physical product with moving parts. When was the last time Google was unavailable (not the last time you couldn’t connect to it, but when it was actually down)? Both Google’s and Amazon’s cloud storage systems are currently sitting at 100% reliability. They’ve never been down. But you’re right, we’re not like MechEs and ChemEs…we’re better. The best of the engineering world tend to go into software, because that’s where the best pay, the most challenging problems, and the brightest future are.

If we designed tangible (physically dangerous) systems the way that software is executed, we would see results of: planes falling out of the sky, bridges collapsing, and cars that come off the showroom floor that blow up into a flaming wreck before they come to their first stop sign.

It’s interesting that you say “executed”, not “designed”, when referring to the software. The user executes it, the engineer designs it. Assuming you meant the way we design and develop software…

Those planes that stay in the sky do so on autopilot more than under human control. They land with automated landing systems. Even when the pilot is making control input, it’s usually on a fly-by-wire system that feeds the pilot’s input to a computer that sends instructions to the motors that manipulate the mechanical controls.

The braking system on any modern car (arguably the most important for safety) is computerized, as are the throttle and engine control. Waymo (Google’s self driving car company) has cars that are safer, more reliable drivers than virtually any human.

Just like with physical products, engineers design and build software to meet a certain reliability level based on the use case. The AV computer on a car doesn’t need to meet the same standards as a self driving system, just like the glove box latch doesn’t need to meet the same standards as the brake pistons.

Boy, many planeloads of people have been partially killed or all killed by crappy autopilots.

Yeah, like Airbus…

The overwhelming majority of aircraft crashes are due do human error. Occasionally some mechanical fault will send the autopilot bad data (like the pitot tube freezing up and giving an incorrect airspeed) and cause the autopilot to execute an unrecoverable maneuver, but I would actually like to hear about a case where the autopilot itself was directly responsible.

Furthermore, a proper software test regime shouldn’t be static. As problems are found after passing tests, new tests should be introduced to cover those failures. Passing California’s political tests or the Army’s tests (with a slightly different design) doesn’t mean those tests are all inclusive. The Remington 700 was accepted by the military as the M24 and M40. They didn’t find that the Walker trigger can fire when the safety is deactivated, but we now know of several deaths that have been attributed to that flaw.

Actually, one of the more damning pieces of evidence in the Remington 700 trials were memos from the USMC on the issue of their rifles firing when the safety was moved to “fire” on the firing line.

I think you may have stumbled onto a little concept I like to call ‘human nature’. The firearms industry is hardly unique in it’s subjugation to human nature, it applies to every industry driven by consumer demand. Everyone buys the crap item first and only after they’re thoroughly disgusted with the quality of the product do they consider spending more for a quality product. Doesn’t matter if you’re buying a toaster oven at Walmart or a house. Working in the residential construction industry, I often inform people that when they just can’t figure out why brand new house A is $25,000 cheaper than brand new house B, it’s because the builder of house B spent $30,000 more building it. Just because you can’t see the difference doesn’t mean the differences won’t become evident once you’re living with (or in) the product.

On the bright side, this phenomena pushes innovation – manufacturers have to build better products at lower prices. Sure, one of my personal faves, the GP 100 is no Python, but then again the Python is no GP 100. The GP is stronger, more durable, less finicky, and much, much cheaper. And S,R&Co didn’t go to the brink of insolvency building it. Perhaps there’s room for Colt to build a limited supply of the Python, but if they want to make it a commercial success they need to make it as pretty as it used to be, but more durable and at a lower price point. This is human nature, AKA – Capitalism.

And this, in short, is why I almost exclusively buy European firearms.

There is only one American firearm company I regularly buy from:

Ruger.

If builders built buildings the way programmers write programs, then the first woodpecker that came along would destroy civilization.

The problem with most “software companies’ is they are run by programmers, not business people. That actually was why Microsoft became a monster company while Apple lagged in the dustbin for so many years. Only when Apple became a hardware company die it become a monster of its own. (Gates understood the business part of software, like no one of his time).

Here’s where I see a problem. Every gun they drop test at the factory is essentially a gun they cannot sell. Really who’s going to buy a gun with a scuffed back plate or rear sight? So they either have to sell it at a discount or go back and refinish it to deal with the surface damage from the drop testing. Also what parts of the gun need to make contact with the ground in order to satisfy drop test requirements? How does the gun need to be dropped? Exactly how high would the gun be dropped from? How much force should the gun withstand?

Perhaps Sig should have rethought marketing a striker fired version of a DAO hammer fired platform without some form of drop safety. They should have just marketed their MHS design instead.

Dyspeptic Gunsmith,a very true statement! The “can’t have your cake and eat it too” expectations of the marketplace just don’t happen. People will always buy the lower cost mass produced plastic and stamped gun and expect it to be like an heirloom Browning Hi Power (not Hi Point). Reality is what it is, can’t make a price point item and expect performance on par with a hand fitted gun from the past.

I always enjoy reading your well thought out comments and I believe what you write! Please never stop commenting.

This is not a cost issue. The P320 runs for roughly the same as other striker fired polymer frame handguns from large manufacturers, none of whom, to my knowledge, have mass produced or sold a handgun that fires when you look at the back of the slide

If the gun ain’t safe, word will get around, people won’t buy it, problem solved.

Yes, that worked in the days of the Winchester 1911, which was a recoil-operated shotgun. That was before the ambulance-chasing lawyers could start to play “Hindsight is Profitable” games with everyone and everything.

Look up the history of the Winchester 1911 shotgun. There is a real reason why it became known as “The Widowmaker.”

No… it’s not solved. It’s not solved for the people who bought the gun without it being possible to know it was unsafe and it’s not solved for anyone who ends up shot because the gun went off without the trigger being pulled.

It’s (current year). Gun manufacturers innovated effective hammer\striker safeties decades ago. There is no excuse for this crap.

Thank you

The problem with designing a meaningful test is that you first have to have a failure mechanism in mind. It’s clear that no one thought there could be enough momentum in the trigger mechanism to fire the gun after an impact to the rear of the slide. During the early days of the single action army revolver, I expect it took a few unintended discharges for people to realize that it was a bad idea to leave a live cartridge under the hammer. I understand it’s possible for an old 1911 to fire if dropped on its muzzle. The firing pin flies forward with enough energy to set off the primer. The question is from what height. If waist high is enough, it’s a valid concern. If you have to be standing on your roof, not really.

As a person who has to design and build hardware to mil-std, the standards tend to be written to cover the most likely or previously observed cases of things that can go wrong. When a new failure mechanism occurs that is critical, you update the standard to test for the newly identified failure mode. Hint: standards evolve as we find holes in them. Based on the Sig P320 and Honor firearm incidents, there clearly needs to be a revision to the existing standard.

Honor could potentially have a major problem that would put them out of business. If you advertise the product is drop safe, but isn’t, event though it complies with the standard, liability will follow. If an accident occurs and a lawsuit follows, a jury will not care that the firearm passes the drop safe standard if there was an identified failure mechanism that was reported to the manufacturer and widely publicized. A major financial pay will occur. Federal legal protections for firearms manufacturers do not apply when real design defects exist, especially known ones that were not corrected.

I agree that firearms safety always needs to be observed, and dropping a firearm is something that should be avoided. That said, sometimes stuff happens, even to the most careful individuals. That’s why firearms need to be drop safe.

I agree.

As one who worked on Japanese motorcycles and Honda cars, this fits my experience (not because they happened to be Japanese, but because this fits the industries as a whole).

Each system on a vehicle (engine, transmission, electrical, suspension, steering, et al), for each model, has failure modes known to the good mechanic. To pick just one: for the early Civics, after about 75k miles, if the customer complained about rough running at RPMs over about 2k, the problem was about 90% of the time bad valve guides. It was a known problem. The solution was to skip the Honda guides when rebuilding the head, and installing upgraded guides (which existed because the Honda guides weren’t very good).

Take your gun with a problem to a good gunsmith, he will have a very good idea of what the problem is after you describe the symptoms, because he knows the gun and it’s failure modes. Since he didn’t make the gun, he doesn’t have his ego telling you that the problem isn’t with the gun. (Are you listening, Honor?)

Testing is good, if done right.

However, testing to every possible mode of failure isn’t possible.

“However, testing to every possible mode of failure isn’t possible.”

I take exception.

This is ‘Murica; corporations owe it to society to build as near perfect in every environment a product as can be humanly achieved. There is no excuse for believing there are “better idiots” out there. Find them, hire them and fix products to defeat those super idiots. We can do it. It just takes corporations getting off their fat bonuses and plowing money into product quality. I know this can be done. Once worked for a company producing autopilots for bizjets. They were having “impossible” failures reported. When I recommended sending company engineers to the bizjet owners and flying with their pilot teams, we discovered that the “bump guard” we built over the controls (to prevent accidental activation/deactivation) were serving as fine platforms for coffee cups between the pilots. The solution was to ban coffee in the cockpit !! See? All it takes is a little effort to make things more perfect, and completely “dummy proof”. You just gotta believe.

And all that jazz.

” It just takes corporations getting off their fat bonuses and plowing money into product quality.”

Yup, but the ‘inconvenient truth’ to that is, when your better-engineered (and more expensive because of it) product is on the shelf, most folks will pick up the similar and far cheaper widget right next to it made in China.

I had a personal experience with this effect.

About 10 years back, I was with my 75 year-old dad in Lowe’s. He needed a roll of electrical tape, so we headed to the electric isle.

On the shelf was a roll of Made-In-USA 3M tape for about $3.50. Next to it was China-made roll that cost fifty cents.

My dad was a kid during WW2. ‘Buy American’ is his usual mode. In this case, he looked at both rolls and put the 3M tape back on the shelf…

Understand. Global competition represents a “race to the bottom”.

Guess I shudda put “/s” at the bottom of my comment.

Good way to divert from the fact that your testing DID NOT include drop testing Nick!

One of the things we tend to do is make the assumption that most products we buy are tested before they are marketed.

Since drop tests are already done (we hope), most of us see no reason to re-test them.

When I buy a new car, I don’t specifically test the brakes to see if they work. I may (do) test them to see if they work to my satisfaction, but not to simply see if they work.

If I’ve just had my brakes worked on, I do test them to make sure they still work. (And good thing, too, as the shop put a guy on my brakes who didn’t know how to adjust drum brakes. The pedal went right to the floor.)

This is a good article and cuts to a major problem here… I’m not sure how it is solved except to very publicly shame companies that decide to save a couple of pennies on each gun and sue the pants off them when someone gets hurt.

The problem is that, on the aggregate, their shareholders (public or private) probably are happier to have the couple of pennies than an actual drop-safe gun.

If I’m a 6′ 6″ tall guy lining up a shot at the range and someone bumps into me hard, I might possibly drop the handgun. So the center of mass will fall perhaps 5′ 6″ before the gun strikes the floor which is likely concrete. Wouldn’t be nice to have some confidence that there won’t be an accidental discharge?

ATFAgentBob is correct that you could burn up a lot of hardware, testing for a great many drop orientations in that test. Which is why the U.S. ANSI testing standard specifies a hard rubber mat over concrete. Oddly, the rubber hardness spec. is a range from 80 Durometer to 90 (shore A). 80 Durometer isn’t really that hard, though 90 is pretty hard.

Here’s a suggestion. Set the rubber hardness at 90 Durometer +/-2. And since the rubber mat produces less impact force than real concrete, why not add another foot or so to the drop height? That means we’re up to a 6.5′ center of mass drop. This, to me, seems like a much more meaningful test than the 4′ drop required by the ANSI test.

We’ve got the NIJ/SAMMI tests, yet for some it’s not enough. Ok, so, what are the absolute minimum standards?

Get that herd of cats to the rail head and then we can agree the guns are safe. Until then, it’s a crapshoot. You cannot know for a certainty that any particular gun can’t be induced to discharge in some way. Unless YOU do the testing and include every possible known combination of angles, heights, and forces, you cannot say “it’s perfectly safe.”

You want to go a step further? Does every AR15 builder drop test his gun? A 1911 assembler? A gunsmith who modifies the action to your specs for competition? Take the SIG P320 case – which for the present does NOT include the M17 – and ask yourself, if the weight of the trigger and specific machining of the disconnector is all that is different, where are you when you install a comp trigger in your Glock?

Absent a vetted and fully certified drop testing protocol adopted by YOUR INSURANCE COMPANY you are in sketchy territory. And tens of thousands of us are – because once you change ONE part, you are no longer in the original assembled condition of that firearm and good luck proving it’s still safe. A few grams one way or another, another foot higher, a concrete floor rather than a rubber mat (which is the NIJ/SAMMI standard) and you don’t know what will happen.

If you disagree, fine, your engineering credentials will suffice, but I’m pretty sure those won’t stand up in court and I do know plenty of engineers who wouldn’t put their career on the line guaranteeing a perfectly safe gun.

They aren’t inherently safe in the first place – over two hundred years of engineering has gone into them to make them fire despite the environment and abuse – because we insist – no – DEMAND they go bang when we pull the trigger No Matter What.

The “safer” you make them the less reliable they are going to be. Nobody worries about a Colt Single Action Army not passing drop safety tests. It’s known for going off if the hammer falls – even resting on a chambered cartridge. It’s why you carry one hammer down on an empty chamber and that is the accepted and recommended method for carry.

If you don’t want your pistol to go off – don’t put one in the chamber. And good luck with that when you need it.

You’re absolutely correct.

The problem we have right now is that neither the NIJ, nor SAAMI, are actual standards organizations. In my engineering career, I worked with a bunch of different standards organizations (ANSI, IEEE, NEMA, NEC). A real standards organization can set conformance requirements in law – eg, various states/cities/counties can say “all new building wiring must conform to NEC 2017 specifications” and ANSI can set standards which will be enforced by contract requirements, etc.

SAAMI is just a recommendation house at the current time – if you want to ship non-SAAMI ammo, you can currently do it. Lots of non-SAAMI ammo is shipped out there – both hotter and colder than SAAMI recommendations. The European counterpart of SAAMI, CIP (aka “Commission internationale permanente pour l’épreuve des armes à feu portatives”) has specs that have the force of law in the EU and member countries.

The only actual test specification of firearms safety/operational issues of which I’m aware currently in use is “Test Operations Procedure (TOP) 3-2-045 Small Arms – Hand and Shoulder Weapons and Machine Guns” from the DOD. You can find their document here:

http://www.dtic.mil/cgi-bin/GetTRDoc?Location=U2&doc=GetTRDoc.pdf&AD=ADA481861

Therein, you’ll see some specs on “abusive handling” tests for small arms – but it isn’t codified quite enough for what we’re talking about here.

Then we have the NIJ ‘standard’ – NIJ Standard-0112.03. They specify a drop test, from a specified height above the floor, with a rubber/elastomer mat of “Shore A” material, 1″ thick, over concrete. You can see their spec here:

https://www.ncjrs.gov/pdffiles1/nij/249929.pdf

I don’t understand the use of the elastomer mat 1″ thick over concrete. How often will one drop a handgun in any attitude onto such material in the “real world?” Probably not ever.

None of these voluntary standards are sufficient to flush out all firearms design issues, nor is there any legal requirement that these standards be met on the production side of gun manufacturing, only on specific government contracts for guns. The civilian market is still pretty much a crapshoot, with ad hoc testing by this, that or some other group, person, blog, company.

I want to see the drop standard to be a AMTRAK engineer? Seems rather low…

Been to McDonalds lately?

That is the standard for TSA agents…… from burger flipper to Hand wand user.

If schools can teach to the tests…

If I owned the company involved, I think I would strive to make my products better in the future…and anyone that wanted to send the item back for repairs would be able to do so…or a replacement…or refund

I own a couple Vektor CP1s…but I know they had/have a drop-safe issue….so I am careful to take that into account…just as I know many of my pistols do not have manual safeties.

Remember the Ford Pintos that blew up when rear-ended?

Live and learn…improve…accept your mistakes.

I used to thing farmers were the whiniest bunch of people out there. Then I started reading ttag.

Perhaps you’re just projecting.

If the firearms manufactures were under the jurisdiction of the Consumer Product Safety Commission many of them would not pass the safety regulations especially the idiotic pre-loaded striker fired guns that do no have manual safeties. There is a mountain of evidence that has accumulated in accidental shootings by law enforcement and civilians alike when using this type of design.

I think too the guns that recently went bang in the drop tests are another example how the firearms companies could not care less how many people they injure or kill in their greed monger rush to make cheaper and cheaper firearms at the expense of reliability. and safety.

The police rely on their guns to work in life or death situations yet greed monger firearms companies continue to put cheap junk MIM cast parts in critical parts of the gun like safeties, sears and hammers. They do it because they make more money using junk parts and they know they can beat most court cases with high powered crooked lawyers.

The problem with industry standards is that they represent the LOWEST bar you need to pass to be considered merely acceptable. Just a tad north of defective.

Meeting every industry standards is meaningless if a gun still goes off when dropped or struck in as tame a fashion as this Honor Guard, or the pre-fix Sig P320.

The difference between Sig’s response and Honor Defense is an issue of ego superceding engineering and ethics in the case of the latter.

I suspect one problem with the testing that gets done is that it’s done by reasonable people who expect people to behave reasonably. That’s a standard my sister refused to allow when she was quality control engineer for a manufacturing company. He solution? The company already had a program that brought in high school kids to learn about the processes used; she latched onto that and had groups of high school students thinking up really stupid things people might do with a product. Just taking the top ten of those inane ideas ramped their product quality up hugely.

These companies would do well to follow suit — grab some university students and let them think up stupid things to be checked by tests, and they’d catch a lot of problems a lot sooner.

note: the local National Guard got a taste of this sort of uninhibited creativity when I was in college; they’d trained against Army pretending to be terrorists and did pretty well, but when they did some exercises on campus with students playing the parts of terrorists they got their asses handed to them. The moral: you HAVE TO think putside the box.

An engineering professor brought in a different news story every week. The story was of a different man who had sex with a vacuum cleaner that mauled his penis. At the end of the semester, he asked his students what these stories taught them. It turns out it was the exact same model vacuum cleaner because vacuum cleaners can be made safe to have sex with, and apparently, most are. The lesson was that people will use the products that the students design in ways they never intended.

There’s only one original drop-safe handgun in the world: GLOCK. Everything else in the market is just plain cheap copycats trying to beat the best, except they just can’t, and keep failing like the rest.