What gunco is the latest to get into the ammo biz? Jumping into the gun food game along with names like SIG SAUER and Browning, Sturm, Ruger & Co. has announced that they’re partnering with PolyCase Ammunition and will offer a Ruger-branded line of the most popular handgun calibers. The big difference here is PolyCase’s lead-free bullets that result in lighter weight rounds traveling at higher speeds, something that impressed our own ShootingTheBull410 when he put their .380 and 9mm rounds through their paces. Press release after the jump . . .

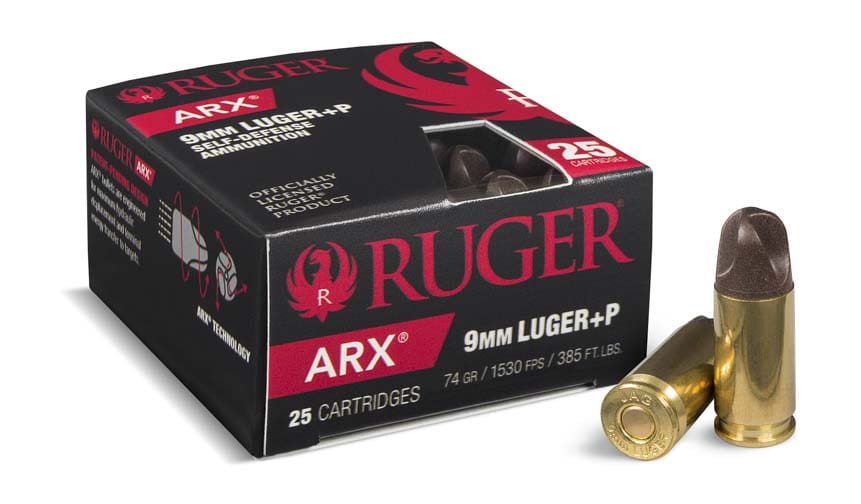

PolyCase Ammunition, the developer and manufacturer of the state-of-the-art ARX® self-defense ammunition, and Ruger®, the nation’s leading manufacturer of rugged, reliable firearms for the commercial sporting market, are pleased to announce that they have entered into a license agreement for PolyCase to produce and bring to market the first ever Ruger-branded ammunition. The new Ruger® line of ammunition will feature PolyCase’s injection molded copper/polymer ARX® projectiles. Initial offerings will be chambered in .380 Auto, 9mm Luger, .40 S&W and .45 Auto.

The PolyCase Story

PolyCase Ammunition® is an innovative injection molding company with over 90 years of combined professional experience. Historically, PolyCase has been in the business of injection-molding precision parts from cutting-edge materials. For the past 5 years, however, their focus has been to develop a technology that delivers light, efficient, accurate ammunition. This technology, which involves injection molding using highly developed metal-polymer resins, has ultimately resulted in PolyCase’s cutting-edge bullet designs, including the patent-pending ARX®.

Through innovative design, resourceful engineering, and the application of state-of-the-art manufacturing processes and materials expertise, PolyCase offerings are tailored to provide the discerning consumer the preferred tools to effectively accomplish their mission. PolyCase products are true game changers in a 140-year-old industry.

PolyCase products are also sold under the Inceptor® brand, which includes the Inceptor® ARX®, Inceptor® RNP™, Inceptor® TNP™ and the Inceptor® Firefly®.

PolyCase Copper-Polymer Bullets

PolyCase worked in collaboration with PolyOne®, a leading specialty polymer solutions and services provider. Using a proprietary, engineered material – a mixture of metal powders, glass-fiber reinforced nylon and other components – PolyCase developed a manufacturing technique for injection-molded bullets. The manufacturing process is very efficient and allows PolyCase to incorporate designs that were previously achievable only through the use of slow and expensive lathes. Through a synergy of injection molding technology, cutting edge design and engineered materials, PolyCase is bringing ammunition manufacturing into the 21st century. Ultimately, it is this manufacturing capability that led to the creation of the ARX® bullet.

PolyCase’s injection-molded bullets result in higher velocity, less weight, flatter trajectory, less felt recoil and decreased potential for ricochets. PolyCase’s RNP™ bullets are designed to function like traditional ball ammunition, and are suitable for range use and target practice. The bullets are tougher than traditional frangible bullets, but still readily break up when impacting hardened steel, resulting in a lower ricochet potential in most shooting situations.

PolyCase’s flagship product, the ARX® bullet, is designed to be a highly effective self-defense bullet. Uniquely engineered for maximum hydraulic displacement and terminal energy transfer to targets, the non-expanding PolyCase ARX® bullet transfers energy to target through a fluid dynamic energy transfer process. Upon impact with a target, the grooves on the surface of the ARX® bullet cause fluid-filled tissue to be compressed, accelerated and forcefully displaced, resulting in a wound channel that rivals expanding projectiles. The fluid displacement effect of the ARX® creates significant wound channels, while ensuring that the bullet is dumping the most energy into the target to avoid over-penetration. All of the ARX® calibers penetrate to the FBI-recommended penetration depths of between 12-18 inches in 10% ballistic ordnance gelatin, and each creates a significant wound cavity in the process. Because the design does not rely on expansion to transfer terminal energy, the ARX® also avoids problems that plague some hollow-point designs such as failure to expand due to low velocity or clogging with clothing, feed ramp issues, and loss of retained bullet weight due to separation of the jacket and core. In this regard, the PolyCase ARX® bullet represents a new generation of self-defense technology.

CURRENTLY AVAILABLE IN: 380 Auto, 9mm Luger, 40 S&W, 45 Auto, 458 SOCOM and 50 Beowulf. 357 Sig, 38 Spl and 223 Rem coming soon.

Interesting. I’m a fan of Hornaday Critical Defense, but I’d give these a try. I’m honestly not familiar with ARX…

Looks like fun to at least test. Damn that’s a zippy 9mm!

Hmmm, interesting bullet shape.

They are very reminiscent of Lehigh Defense’s Penetrator design, to the point where if Lehigh Defense has patended the design, I would not be surprised if they sued over infringement.

You’d be surprised. The function is very different and the rounded nose is a big reason. This bullet is designed to shred and tumble while the penetrator is designed to punch through. I think the mass balance of the bullet is rather drastically different. I really don’t see a patent suit having much of a chance given the obvious difference in performance.

Both the Lehigh and the PolyCase projectiles have fluting intended to cause would cavities via compression and redirection of fluids as the bullet moves through tissue.

That’s the main damage mechanism from each – not expansion of the round, or multiple would tracks from fragmenting, but by hydraulic-pressure-driven cutting of surrounding tissue.

The Germans in WW2 had developed an identical projectile in 9mm for their sub-machine guns that was supposed to be L.A.P., but they quickly found out it was terrible on rifling.

I’m actually interested in actual polymer cased ammunition. The DoD has been working on that for years and some companies have very useful prototypes.

A similar thought occurred to me. What if they used the shotgun shell concept where you have a plastic shell attached to a brass base? In pistol calibers the brass or steel base would be sufficient for the extractor rim and to hold the primer and the rest of the cartridge/bullet would exit the barrel when fired. If the entire front end was made of this polymer composite it seems like that would be feasible and would add somewhat to the projectile weight. It might also mitigate some of the propensity for tumbling as the projectile would be longer.

http://www.pcpammo.com/

They have blown up a few rifles (fluted chamber = kaboom with plastic casing apparently) but this is still what I’d say is in it’s infancy.

As a reloader I’m all for this, the brass casing is by far the most expensive component. I wouldn’t stop loading match rifle ammo, but I reload 9mm strictly for economy and I’d happily digest tons of cheap plastic cased factory practice ammo.

It’s the same reason why aluminum and steel cased ammo is so popular.

On a side note. I’ve seen complete polymer .50 BMC casings. The hybrid approach saves weight, but it not actually any cheaper.

The main reason why they’re pursuing polymer cased ammo is actually weight saving. If you can trim, say, a third of the weight per round, that’s 8 mags carried instead of 6 for the same load-out weight.

Tumbling is a plus with this projectile. It enhances the chances for a debilitating wound.

Back in the 80s I got a couple of boxes of shotgun shells that were all plastic case save for the primer. They were in 20 round boxes and much cheaper than any other shells. I was told they were made in Poland but wouldn’t swear to that.

I only saw them briefly and only in 12 ga.

What’s the main short-coming of polymer cases- heat resistance, durability, reliability?

It would be nice to cut the cost of practice & training ammo by X% over all metal shell casings.

The main shortcoming right now is that they don’t really work reliably yet. Can stick in chamber, split etc.

It’s still miles ahead of where it was when the people working on it started that project, so it may well deliver a solid round yet.

The good news is that this is a US military project, and so the rounds undergo very rigorous testing compared to your typical commercial ammo. So I expect that once they pass all those tests, they’re good to go.

http://www.luckygunner.com/lounge/pcp-ammo-review/

74 gr

Not that I’m planning on carrying in Jersey soon, but I wonder if this ammo (and the Lehigh Penetrators) are legal in states that ban JHPs. Anyone know?

Jersey banned JHPs? Don’t they understand that JHPs are designed largely to prevent the round from going through a person, and thereby not killing someone behind them?

The NJ ban is on “dum dum” bullets. Given that they deliberately leave this term undefined… Yeah, not good.

I’m surprised you’d be able to carry anything in NJ. Permits in that state are harder to get than liquor licenses.

“Dum dum” bullets? Thank God the sepoys are safe in New Jersey!

I don’t believe the British Army’s Dum Dum Arsenal, originally located near Calcutta, India, is still in operation. So I highly doubt there are “Dum Dum” bullets in New Jersey.

From an energy standpoint the .40 and .45 versions are little different than Federal Hydroshocks. The 9mm looks marginally more potent than standard 9mm JHP. I want to see some independent tests before forking out the money. We have seen a lot of wunderammo fail to live up to company claims when subject to independent testing.

Ballistic gel is all well and good for initial evaluation, but before I put this in my EDC and depend on it for my personal safety I want to see how it actually affects a living target. Whne there are studies available discussing how effective it was in actual use, then I will give it further consideration.

The interesting part here is the wound channel profile, really, not the energy per se. If these are like Lehigh, you get a nice balance between penetration and permanent wound diameter.

Physics-wise, I think it plays out like this. FMJ bullets get best penetration, because all of the energy goes into that – but don’t expand, so damage is limited to their diameter (plus “hydrostatic” shock, if any). SP and HP expand, so wound cavity is larger, but their penetration is correspondingly limited, because part of the energy goes into creating that larger wound channel, and part goes into expanding the bullets. Lehigh XP and this design create a larger wound channel without having the bullet expand, so all the energy that is spent on doing so is instead going into extra penetration.

I got my ass lit up over on TFB since the article they posted claimed the 9mm 74gr load could be compared to a .223 75gr BTHP – obviously a ludicrous statement – and I had the gall to call publishing that claim from the manufacturer irresponsible.

Glad to see that statement is not present in TTAG’s version, even if it is the manufacturer that removed it from the presser.

Sure why not? Not that I can’t get cheaper rounds that work as well. If I get in a gunfight stopping power will be the least of my worries…

Sure why not? Not that I can’t get cheaper rounds that work as well. If I get in a gunfight stopping power will be the least of my worries…

2nd double post in 2 days-not MY fault. When are you guys fixing the edit function???

I hope this is as good as SIG Sauer elite V-Crown!

…

*cough

HA I see what you did there.

One more supplier of non lead ammo. Good. For those of us in CA it’s nice to have options. I have BB coppers for my .38 when I carry in the sticks and have my hunting license upon me.

How soon is “soon”? I’d like to try their .38 spl.

Buy ammo. No double standards put DC politicians on Obamacare and SS.Thanks for your support and vote.Pass the word. mrpresident2016.com