Daniel Defense has announced their first suppressor, the DD WAVE. Built for .223/5.56, 7.62 and .300 Win Mag ammo, the one-piece 3D-printed WAVE is available in direct thread ($986) or quick detach ($1157) models. Here’s their press release:

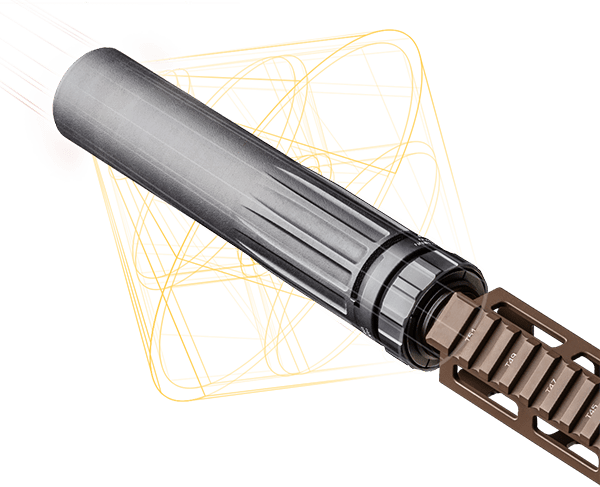

Black Creek, GA – Daniel Defense, manufacturer of the world’s finest firearms and accessories, has released its first standalone suppressor, the DD WAVE. The 7.62mm sound suppressor, which features an innovative 3D printed construction and unique overlapping-baffle design, is available with a quick-detach Acme Thread Quick-Clamping System or a direct thread application.

“The DD WAVE is unique because it’s constructed entirely using 3D direct metal laser sintering technology,” said Daniel Defense President/CEO Marty Daniel. “We are able to do things with this type of manufacturing that you simply can’t with a conventional machine. The one-piece design, constructed from Inconel, eliminates the need for welds, which are usually the weakest parts of a suppressor. So what you’re left with is a suppressor of unmatched strength and durability.”

Making its first public appearance at the 2017 NRA Annual Meetings and Exhibits in Atlanta, Georgia, this past April, the DD WAVE has since created quite the buzz within the industry. Named in part for its advanced cascading baffle geometry, the DD WAVE features a design that cannot be duplicated through more traditional manufacturing techniques. The utilization of 3D printing technology allows for a one-of-a-kind baffle design that forces gas into concentric, confined spaces, extending dwell time in the suppressor and resulting in a product that more effectively attenuates sound.

The DD WAVE is available in both quick-detach and direct thread options. The quick detach version features Daniel Defense’s proprietary Acme Thread Quick-Clamping System that won’t carbon lock and securely clamps the suppressor to a 17-4 PH stainless steel muzzle device, making it easy to remove even after extended use, while the direct thread version features a traditional thread to barrel application. Constructed of Inconel, stainless steel, and titanium—and then Cerakote coated—the DD WAVE is fiercely strong yet lightweight, making it durable, unobtrusive, and reliable enough to accommodate a wide variety of calibers ranging from 5.56 mm all the way up to .300 Win Mag.

MSRP for the DD WAVE Quick Detach version with included muzzle device is $1157. The direct-thread version is $986. Both are available from authorized Daniel Defense dealers. To learn more about the DD WAVE, visit www.danieldefense.com/wave

About Daniel Defense

Located in Black Creek, Georgia, Daniel Defense is a leading manufacturer of premium firearms, rail systems, and accessories. Its iconic brand remains unmatched in quality, precision, and world-class customer service. President/CEO Marty Daniel founded Daniel Defense, which started out creating rails and accessories for the AR-15 platform in small batches. Today, with two locations and a combined 137,000 square feet of manufacturing space, Daniel Defense continues to make quality rails and accessories and the world’s finest firearms for civilian, law enforcement, and military customers.

For more information, visit www.danieldefense.com.

I’m going to look at getting one of these.

HPA / HUSH now please.

Good luck with that. Republicans wouldn’t piss on the President if he were on fire. Much less cooperate on legislation that will be vigorously opposed by the lefties.

I’m afraid the RINOs are too squeamish for anything meaningful to pass. It seems this GOP controlled congress is too opposed to itself to ever allow any effective conservative legislation to pass.

Hank, they aren’t squeamish. They are making way too much scratch off the existing system. Why would they change? The swamp is a very lucrative place for politicians of all party. They just want one of themselves in charge.

Very true.

I wish it was as simple as that. Any pro-gun legislation will take 60 votes in the Senate — and their aren’t 8 dems that will back it.

Ain’t gonna happen since it unfortunately takes 60 votes in the Senate to pass any gun legislation due to cloture rules. Don’t think we have any good news to come other than additional judicial appointments.

Closure rules aren’t set in stone. The GOP can change the system to require 51 votes at any time.

My main interest is integrally suppressed, shorter barreled uppers that achieve a 16″ OAL for a 1 stamp product. I wish these companies would produce stand alone barrels like this for purchase. I’m not really interested in screwing on an 8″ can onto a 16″ barrel. Lol. I’m interested in a new can myself and am considering the new Gemtech upper or one of the Amtac, over the barrel suppressors that only add less than 4″ to thr OAL. STILL, I own a DDM4V11 that I wouldn’t mind having this new Wave technology for. Would like to see some testing with it.

Check out hardened arms . They juat had an 1 stamp gun like that for a fair price. I own several cans . I’m an ffl/sot. Not pitching them . Spikes and DD has them but the cost are insane juat for the upper

…eliminates the need for welds, which are usually the weakest parts of a suppressor.

I’m not a welder but I recall being told that a proper weld was supposed to be stronger than the surrounding metal?

That’s what the welders want you to think. 🙂

Why is it that when I read “Daniel Defense 3D Printed”, my brain interprets it as “Defense Distributed 3D Printed” and thoughts of high end DIY suppressors dance in my head?

Too bad. You’d pretty much have to sell your soul to afford the machinery it takes to make these. Laser sintering machines are crazy expensive even for plastic. I can’t imagine what one for metal costs. That’s also not even considering the equipment required for post print processing (3D printed metal objects aren’t ready for use directly out of the printer like most plastic printed products)

I remember hearing not too long ago about a machine shop that built a 1911 on a laser metal sintering 3D printer (I believe the barrel was still conventional) and the guy that built it said that the machine was $1 million, in addition to the finishing tools. I wonder if the same machine that did it with carbon steel could do inconel, something tells me no and that machine would far surpass a million

Oh, and the whole point of the article was that anti-gunners were flipping out thinking it was actually like that defense distributed plastic finger dismemberer and the guy that built is was like “relax, the equipment to do something like this is ungodly expensive and you’re not going to gave dudes chugging these out in their garage”

suppressors are becoming like Apple products. Each new one made costs more for no reason what so ever. the way the suppressor market works is in direct contradiction to supply and demand. with so much supply, prices should be falling. but they wont because these companies know alot of people buy them just because they are expensive and you can brag about it.like this is fucking high school or some shit. there is absolutely no reason why suppressors still cost so much. I, for one, am not feeding this pig until prices come down. eventually someone will see a large demand for a quality, not gold standard, cheaper suppressor and make it for common, mature man who doesn’t have to turn every outing into a dick measuring contest. its so pathetic going to the range and you see guys ( grown boys i should say) looking around every time they fire to see if anyone thinks their cool. as if the only reason they bought it was to brag like a damn teenager. \rant

3D printing with lasers isn’t cheap. And cans never sell for MSRP so this will be a couple hundred less retail. And DD is known for producing high end stuff, that in reality is overpriced. If you’ve been paying any attention to the suppressor market, you will have seen a ultitude of companies start producing suppressors that are much, much cheaper than this one

And you don’t have to take part in the system until prices come down. More cans and less wait time for the rest of us. Enjoy your noise stick.

Like 338 said, 3D printed metal products are difficult and expensive to make.

The big costs for this product would’ve been research. Because it’s printed, I’m sure there’s an unusual baffle design inside that couldn’t be accomplished (at least not economically) with traditional machining techniques. Add to this the time required to verify that it won’t blow itself apart or have pieces shear off inside (3D printed stuff is more prone to this issue due to the nature of production).

So….how quiet is it, and how effective is it in reducing back pressure? Full auto rated? Sounds like someone needs to test and compare to other popular products. I don’t care how it is made, show me how effective /durable/price justified it is.

I’ll just do Form 1s and build my own. Already did 2, 5.56 and 30 caliber.

WAY cheaper.