Polymer AR-15 lower receivers offer light weight, surprisingly high strength and, most importantly, very low cost. Historically they’ve been a bit of a mixed bag in the quality department, mostly due to fit issues caused by molding imperfections. StarLos Firearms has set out to improve on past offerings from other manufacturers by improving the polymer and improving the manufacturing process, and we were happy to put their SLF-15 complete lower through the wringer to see if it worked. 500 rapid-fire rounds? Check. Run it over with my truck? Check . . .

My go-to FFL, Best Buy Surplus, intends to be one of the largest stocking distributors of these lowers in the country. At an MSRP of $119.99 for a complete, ready-to-run lower and $59.99 for a stripped lower, they’ll be some of the least expensive options anywhere. The guys at BBS asked if I would provide an honest review ahead of them stocking these things in quantity, and even donated 500 rounds of Federal American Eagle .223 to the cause. If you like what follows and need an SLF-15 in your life, call BBS (509.535.5375) for the best pricing. They’re happy to ship to your FFL.

Initial Impressions

The receiver itself looks and feels really great. It seems stronger and is definitely much cleaner and more precisely manufactured than the New Frontier Armory lower that I’ve used as a desk ornament and pen holder for a couple of years. This met expectations, as improving the fiber reinforced plastic formula was a primary goal of StarLos. To improve fit and finish, the lower isn’t actually molded into its final form. Rather, billets of polymer are made in the rough receiver outline and then the lowers are CNC machined from those.

So while the stripped lower appears about as good as it gets in plastic fantastic world, I had serious reservations about a fire control group, magazine catch, takedown and pivot pins, and receiver extension (buffer tube) made entirely of polymer.

StarLos is definitely not the first to do a 100% polymer AR-15 hammer, trigger, and disconnector, but the whole idea of this has seemed so absurd to me that I’ve avoided them like the plague. At this point I suggested to Best Buy Surplus that a review of the lower would be meaningless without putting a bunch of rounds through it, and thought maybe StarLos would donate 500 or even 1,000 gun food units. No worries, said Bill of BBS, setting a box of AmEag on the counter. Hmm, nice.

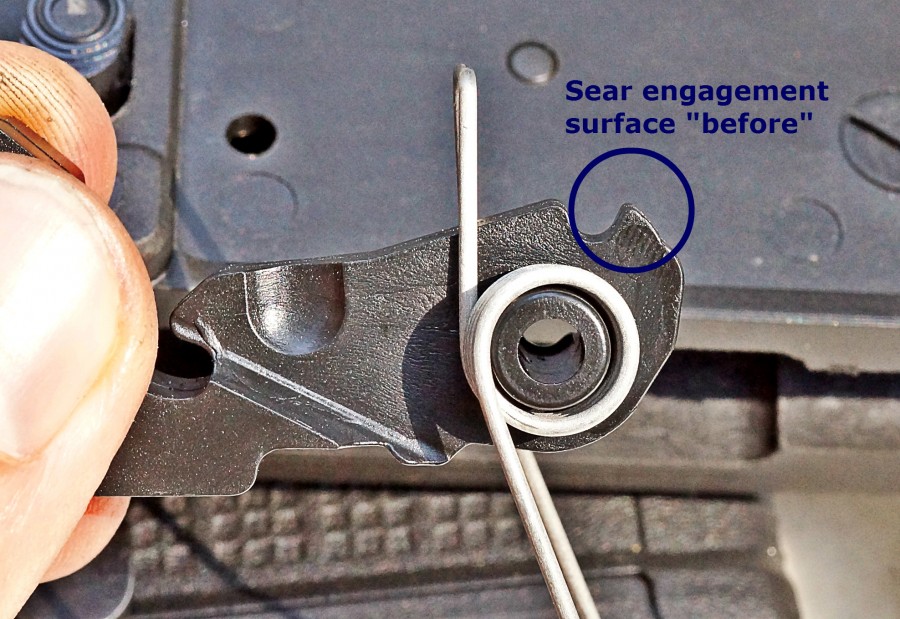

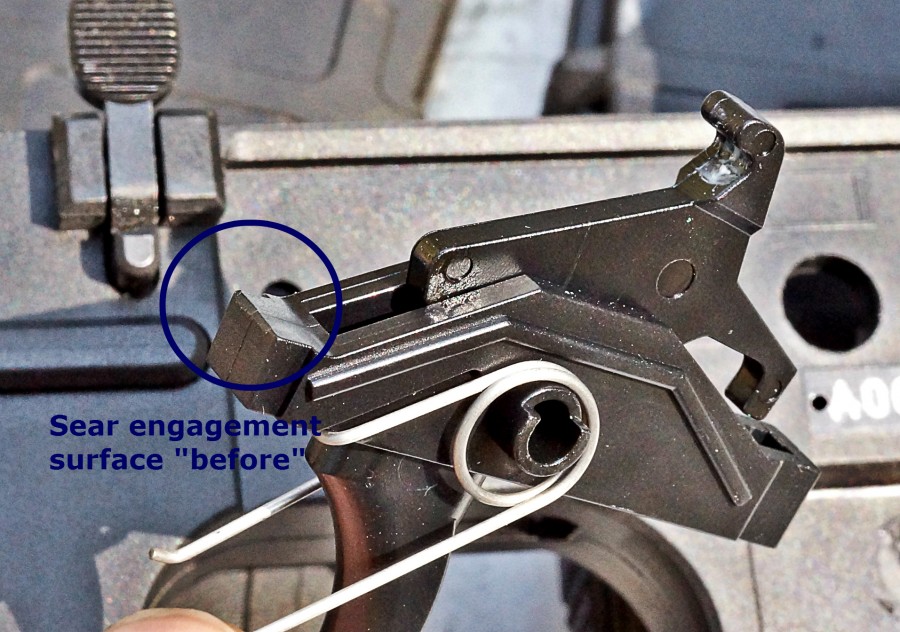

Well, I begrudgingly had to admit that the trigger pull actually felt good. Much better than most parts kit or otherwise “mil-spec” AR triggers. Less creep and significantly smoother than parts kit, with a pretty clean break at just over 4 lbs. The lightweight hammer in combination with a full-power hammer spring is supposed to ensure reliable ignition of even stubborn primers and a quick lock time. Yeah, but do the sear engagement surfaces hold up? More on this later…

Dimensionally, almost everything appears to be in spec. My go-to upper from Adams Arms bolted right up, every magazine type I have functions properly, and aftermarket trigger units, safeties, and grips all went in cleanly. The only exception I found is a nub on what’s normally the flat side of the safety bar. It’s designed to work with the polymer trigger, but would have to be filed off to work with a standard replacement trigger.

On The Range

One 40-round and two 30-round magazines accompanied me to the woods along with the 500 rounds of AmEag and the SLF-15 wearing an Adams Arms hat. I figured I’d mag dump 100 rounds from those three magazines, take a few minutes reloading while the rifled cooled down, and repeat until all of the ammo was gone or some sort of parts breakage occurred.

The result was 500 empty cases. That plus 150 rounds of 9mm and I had a good, if noisy, Sunday morning.

However, it wasn’t all smooth sailing. In the video at top you’ll see my usual close-up of the trigger pull and reset, done before I had shot the gun. After one of the pulls, while releasing the trigger slowly to get a good view of the reset, it never came. The disconnector didn’t pop off the hammer. This same issue reared its head maybe 10 times while shooting. To fix it on the range, I pushed forward on the back of the trigger or just pulled the trigger back again and flicked my finger off it.

Basically, it wanted to stick some of the time if I let it out too slowly. Keep in mind I removed the FCG to take “before” photos of the sear engagement surfaces and, while all of the parts other than the disco (to include trigger pins, safety bar, etc) were as dry as the Atacama and the trigger fit was a touch snug in the receiver, I chose to shoot it exactly as I got it. As I later confirmed, some lube and a wee dab of judicious filing would have entirely prevented this problem.

Speaking of sear surfaces, I truly figured they would wear away and round off pretty much immediately, which is why I did “before” and “after” photos. I’m shocked to report that, after 500 rounds — including a couple mags of bump firing that almost cost me my camera haha — I cannot see any difference in the hammer/trigger or hammer/disconnector engagement surfaces whatsoever. Not even the slightest bit of change. But seeing is believing:

So, color me surprised. And impressed.

Unfortunately there was one more problem near the end of the shooting session. The castle nut worked free and, while trying to determine why the bolt suddenly started sticking in the receiver extension, I spun the entire stock. This caused the buffer retainer and spring to pop out and the receiver plate to spin, which caused the takedown pin detent and spring to head for the hills.

As mentioned, the loose stock initially caused a hangup on the bolt carrier, but once the buffer retainer dropped into the FCG pocket it actually ran fine until all 500 rounds were downrange.

Aside from these two issues, the receiver worked smoothly. The safety functioned crisply and properly, the bolt catch did its thing before and after every magazine change, the mag release worked smoothly, the grip stayed attached, and the receiver pins didn’t even explode.

Really, everything still looks new.

Oh, yeah. I also ran it over with a Nissan Xterra. The whole thing’s in the video, but…

It got dirty but otherwise didn’t care one bit.

Conclusions

My experience with the SLF-15 complete lower wasn’t perfect, but I still think it has a place. The issues it had weren’t due to use or due to parts failures — they weren’t due to the parts being plastic — but due to poor assembly. In fact, the magazine catch needed another rotation before it was properly installed. No, not exactly confidence-inspiring but had I checked the castle nut and lubed the FCG like I wanted to, I’m fully confident it would have sailed through the 500 rounds without a hiccup and kept on going well into ammo-induced indebtedness.

I can also see picking up a handful of stripped lowers for SHTF or some sort of gun grab hedge investment. They’re so affordable, they can be a backup to the backup. Heck, the polymer’s supposed to be impervious to everything so bury it in the ol’ backyard and it should be right as rain even if the zombies don’t come till 2073.

Specifications: StarLos Firearms SLF-15 Complete Lower (copy-paste from SLF website)

- LIFETIME WARRANTY

- Winter / Oversize Trigger Guard

- Works on any Mil.Spec Upper Receiver

- Multi Caliber Supported

- NEW billet Design

- Extremely high chemical resistance

- 4.7oz for a custome light weight AR 15 build

- High tolerance to heat

- Color is black

- Carbine Buffer and Spring

- Steel Castle Nut

- Steel Locking Ring

- 6 position collapsible commercial M4 style stock

- SLF 4lb trigger group polymer

- 2.6oz commercial polymer buffer tube

- Standard A2 Black Pistol Grip

- DOES NOT COME WITH PMAG

Made In USA. The SLF-15 Weighing in at 25oz with the polymer trigger group and 2.6oz polymer buffer tube make this the lightest complete lower on the market today,The SLF trigger group has been heavily tested and despite heavy carbon build up after thousands of rounds the 4lb trigger maintains its crisp, fluid pull all the way through. Corrosion resistance of FRP is a function of both our resin content and the specific resin used in the laminate. The SLF trigger group is also back with a LIFETIME WARRANTY.

Ratings (out of five stars):

Ergonomics: * * * *

Three stars is average, and this is a standard AR lower with standard grip, standard stock, standard controls, etc. So, average there. Plus one star for extreme light weight and noticeably better than parts-kit trigger.

Reliability: * *

I’m actually totally confident that this setup is reliable for thousands upon thousands of rounds if assembled properly. If the trigger group was lubed and fit a little better and the castle nut was properly tightened, this rating would have been totally different. On the plus side, there was none of the extreme wear I expected to see on the polymer trigger parts. In fact, there was really no wear visible at all. The polymer hammer does solidly dent primers, and the buffer didn’t even shoot out the back of the polymer buffer tube and impale my shoulder. The polymer that the receiver is made out of is extraordinarily strong and resilient, and may even hold up to more abuse than aluminum.

Customization: * * * * *

Well, it’s a dimensionally in-spec AR-15 lower receiver so you can do whatever the heck you want to it. Or, of course, stripped lowers are available for half the price and can be built out from scratch.

Overall: * * * *

Rated against other polymer lowers that I’ve owned and shot, the StarLos lower is noticeably nicer. The quality of the polymer is clearly better — it’s stronger, denser, harder (yet still flexes rather than cracks) — and the machining and tolerances are better. Despite this, the price remains at rock bottom. Minus one star because of sloppy assembly. If I were buying an SLF-15 complete lower, I’d give it a thorough once-over.

[Edit] Guess what? It passes “the push-up test.” If you must know, I’m 6-foot, 190…

The buffer tube flexes a little but the receiver itself holds pretty firm. I think with the stock all the way out, the buffer tube would kink or crack. But I’m not testing that yet, as I’m hoping to measure how much force of this sort is necessary to actually crack the receiver in order to compare that to the amount of force required to do the same thing to a standard, forged aluminum lower.

The buffer tube flexes a little but the receiver itself holds pretty firm. I think with the stock all the way out, the buffer tube would kink or crack. But I’m not testing that yet, as I’m hoping to measure how much force of this sort is necessary to actually crack the receiver in order to compare that to the amount of force required to do the same thing to a standard, forged aluminum lower.

To paraphrase The Graduate: “One Word: Metal.” Plastic is for Super Soakers and Nerf guns

So, should I come over to get all of your Glocks and M&Ps now, or would you prefer I just send you a mailing address?

I have the same question regarding any PMAGs you might be in possession of.

Oh boy, another plastic gun–just like a kiddie toy! Imagine the manufacturer’s profits from this piece of dreck.

Folks said the same thing about Glocks, and first generation M16’s.

I don’t have any problem with the material they are made of. I’d bet they will run just fine for a very long time. The stories about them breaking when dropped makes me iffy on them. I just don’t see the value/benefit. You can pick up a complete Spikes for about $200 on gunbroker now. For only a few bucks more than that polymer one you can get a decent quality “metal” gun.

1. It’s lighter.

2. You might not even care about the extra toughness if you’re building, say, a dedicated .22 AR.

If you bave a problem nust replace the plastic fcg, put on a 22lr upper and call it a day.

Ive used an Omni polymer upper for going on 3k rounds of 223 and its been just fine. We also dropped in a RDIAS and changed the parts and it worked just fine. I think people make too much of a deal over polymer lowers.

It’s like when the M16 first came out — heck, it still gets ribbed for the same reason — and everybody called it a Mattel toy for all of the plastic and aluminum in/on it. Aluminum wasn’t even considered “metal” as far as firearms were concerned. Some of the nicest AR-15s on the market today heavily feature polymer as most of the buttstock, grip, handguard, magazine, etc. And we still hear crap every day about the “tupperware” pistols, despite GLOCK obviously proving beyond any sort of doubt over the last 30 years that they’re as strong and durable as metal frames.

The lower receiver sees little stress compared to the upper. It holds the trigger parts in place and its hardest job is keeping the buttstock on. I’m not convinced that aluminum is stronger for either of those tasks than a high-grade fiber reinforced plastic like this. I think aluminum looks and feels nicer, but I don’t think it’s stronger or more durable or otherwise superior. I’ve cracked an aluminum lower before (speaking of investing for gun grabs, that cracked, stripped DPMS lower sold in Feb 2013 for $275 haha) and given near-equal strength there’s certainly some advantage to a material that can flex and spring back instead of one that’s brittle.

Of course, I’d love to actually stress test the rear of the receiver — the threaded part that holds the buffer tube — against a standard forged lower. Put ’em both in a bench vice and see how much force is required to crack that part of the receiver off, which is likely the #1 physical failure on an AR lower regardless of lower receiver material.

Easy stress-test: Put a standard upper on the poly lower and drop it from chest height, canted slightly so the buttstock impacts the ground first, and see if the receiver snaps right at the buffer tube threads. That’s how and where my polymer lower broke (see below post) and I’m interested to see if this new gun’s polymer is truly stronger than normal.

I think most folks do the “push-up” test. Balance the lower across the grip & magwell or grip & an inserted magazine (or, heck, just on an inserted magazine) and then do a push-up while pushing on the buttstock and the handguard. There’s no way on earth this lower would make it through that, as the plastic buffer tube would definitely crack or kink. I think that would break way before the rear part of the receiver. I wouldn’t trust an aluminum lower to make it through this test any better than this polymer lower (with a metal buffer tube) though. That same place your lower failed is also the most common point of failure on an aluminum lower, and it isn’t hard to snap one through there.

Well, push-up test complete 😉 . It passed. Pics added to the review after the ratings…

Nice. I guess the StarLos is pretty durable.

I used to own an Omni poly lower, then it broke clean in two. Not from firing, but from being dropped on the ground from chest height. It snapped where the buffer tube screws into the lower. It was a gen 1 (I probably got one of the last gen 1s) and the ones they make now have metal in that area to mitigate the problem, but all polymer lowers earned a reputation for fragility for a reason. They may have grown past that weakness, but it was a real thing at one point.

As mentioned, that’s where aluminum lowers break as well. It’s definitely the weak point on a lower (just google broken lower receiver), I just remain unconvinced that a quality polymer would break more easily than aluminum. And I definitely don’t think molding the polymer around a small zinc insert like OMNI did in their Hybrids is going to increase strength vs making it from 100% FRP.

Look up a video called: LW-15 Polymer AR-15 receiver Torture Test #3

Cramming it full of dirt and shooting it out, running over in in trucks, slinging it 25 yards through the air, using it as a loading step, .. it’s beefy. I mean realllly beefy.

This one, the Starlos? Couldn’t say..

These look cool, ~4oz weight savings is a nice thing for say an AR pistol that’s a toy anyways.

Polymer lowers usually have problems with buffer tube support. That’s where you need to test the durability, the way you ran over it was a joke. The funny thing is that you were already having problems with the castle nut without putting it under any real stress,

The only one i would ever trust is the CAV-15 lower

The way the CAV incorporates the grip and stock into the unit as well likely does provide a bit of reinforcement to that notoriously weak part of a poly or aluminum lower. What I’ll look into finding out is how much force it takes to crack this StarLos there vs. how much force it takes to crack a standard, forged lower there.

BTW the [steel] castle nut was simply loose. I’ve encountered a couple of loose ones on “normal” ARs as well. The one lower I have that uses a castle nut has a dab of blue threadlocker there and is torqued to spec.

I like my cavarms lower. The buttstock is a little short, so I added a slip- on recoil pad to add length of pull.

I like CavArms lowers – great trigger, by the way! – but I wish they made some more extensive arrangements for sling mounts. As it is, it just has this one slot, and it’s not even particularly conveniently oriented.

Also, the one I have is weird with magazines. The .223 mags all lock in fine, but some release very easily, with barely a touch of the button. Some of the .22 mags (notably, BDM with steel feed lips) don’t lock in at all.

I buy most of my lowers stripped so a $40 Anderson or $49 PSA (via LW Schneider or Aero) are my normal go-tos when I get the itch to play with legos.

That said, I picked up 3-pack of New Frontier Armory poly lowers at a super discount some time back so I could build a few ‘test’ lowers to try them out. My anecdotal experience has been:

• None have given me any issues from a functionality standpoint.

• The stock plastic FCGs in these all have lower pull weights than the average GI triggers I’ve installed over the years.

• I am a bit iffy on the plastic safety and hinge pins. I pull my halves apart quite a bit in swapping numerous uppers around for testing and the channels on the hinge pins show a fair amount of wear.

• They get a bit ‘flexy’ if you leave them out in the desert sun. However, recent FN ‘bendy’ frames seems to make that a polymer thing. Surprise, plastic bends when heated.

• I don’t run over my lowers with trucks. 😉

I still buy my Anderson and PSA lowers for $40 and $49. The New Frontiers polys are now used for:

• One on a dedicated .22LR upper

• One as a Iron Sights trainer for my boys (with all pins, FCG, etc., replaced with metal parts)

• One with a SIRT-AR laser trainer (you swap out the BCG and part of the FCG) with a set of LaserLyte training targets. These are interesting for indoor training. And really helped my youngest with his standing trigger control and grouping (as it translated to the actual range).

I think I’m gonna buy an Anderson to see how easily it breaks compared to this one haha. Maybe I’ll even snap my New Frontier Armory lower but I have been enjoying it as a pen holder so that would be kinda sad. Actually, I guess it’ll still work for that even with the receiver extension trunnion thing snapped off. I do firmly believe this StarLos would prove markedly stronger than the NFA one. The polymer looks and feels superior in every way. Where it’s milled, the fiberglass (or whatever fiber) content is very apparent.

I recall reading a guy from Lancer once say that their translucent magazines are actually stronger than opaque ones precisely because they do not have any kind of fiber in them (which they need to have for colored mags, because the polymer they use is otherwise naturally transparent) – and that particular polymer is stronger when it’s solid than when it has some foreign matter inside, producing internal stress point. So taken at face value, it would imply that it all depends on what kind of polymer they use.

Since tinkering to fix things, broken or not, this would work for me. Still, I’m kicking myself for not buying one particular lower offering where the safety markings were a peace symbol, and a middle finger. Just the kind of tasteless humor I love.

the only use i have for an ar lower is to launch soda cans. this seems like just the ticket for my first foray.

I guess I’m missing something, starting with “what problem does a poly lower solve?”

Lowers are now so inexpensive, it isn’t the expense.

Lowers are made out of aluminum, so it isn’t a weight issue. Yes, people will tell me that this is lighter than a 7075 lower with parts on it. I’ll put those people obsessing about weight/mass of an AR-15 in contact with the people who are obsessing about muzzle brakes for a .223 because they have some issue with the “recoil.” Maybe these two groups of people can figure out whether they want lower recoil or lower mass in the rifle. You can’t have both, so says some English guy who sat around under apple trees while pondering higher mathematics.

Anodized aluminum doesn’t corrode easily, so it isn’t that.

I doubt a poly receiver would allow you to butt-stroke anyone better than an aluminum receiver. There are some aspects where the M-16/AR-15 will never exceed the capability of a Garand or M-14 (or 1903, for that matter). Bayonet and blunt force are two of those issues.

And plastic/composite/polymer/cheez-whiz trigger/sear/hammer surfaces? Whaaaa? You’re not serious.

No. No, no, no, no, no, no and no. No.

All I see from composite trigger/hammer/sear engagement surfaces is a huge yawning sinkhole with a horde of hungry lawyers at the bottom of it…

Oh, and before some chirpy kid pipes up and tells me “You’re just an old man who is out of date and out of touch, go back to snuggling your Mausers,” I’ll NB that I have a CavArms lower under a A3-style upper. As I’ve mentioned to the AR fanbois here on TTAG before: “I probably own more AR’s in more configurations than you do.”

It’s a similar situation in the road bike world. ‘Weight Wienies’ blindly obsessing over grams of mass on bikes pushing 10 grand and then crying when they break.

You have valid points as things stand currently. ‘Real’ lowers have gotten so cheap it doesn’t make any sense from that perspective. The advantage they used to have was cost. 4-5 yrs ago I got a Plum Crazy complete lower for something like $110 delivered. That was very cheap at the time and didn’t hurt that is was/is a little lighter than a standard lower. Novelty was the main thing for me though. I still use it as a dedicated .22 and have had no problems.

If the SHTF or I had to parachute into Uzbekistan for a secret mission a plastic lowered AR isn’t the gun I would grab, but they have a place. I do think they should be $25 or so to compete.

I wouldn’t take one into battle either, but I also don’t see another way to end up with a complete lower for about a hundred bucks. And as other folks have mentioned there’s a place for that as a backup, as a dedicated .22 or “teacher” lower, for a can launcher upper, an investment just to hang onto and sell when the time is right, etc etc… And in the meantime it can be a pen holder & paperweight on your desk 🙂

Perhaps coming someday soon, Dyspeptic, will be firearms built from bubblegum, used toilet paper, and the power of positive thinking.

It helps significantly in the problem area of AR pistol weight limits. Here in the People’s Republik of New Jersey, an AR pistol has to be under 50 oz. in weight. Since your barrel has to be steel, right off the bat you’re losing 25% of that weight limit to your barrel.

I’ve worked out a spreadsheet with various über light-weight components to get it under the 50 oz. limit, but many of the pieces get pricey in a hurry when you’re shaving grams here and grams there. To get a 25 oz. complete lower for a reasonable price is quite nice. This is not a pistol lower (obviously) so it doesn’t exactly solve that problem 100%, but it’s a good start. Maybe one day they will offer a turn-key pistol lower.

25 oz includes the buttstock, too. A pistol version w/ polymer, pistol buffer tube would be a few ounces lighter. Actually, that buttstock probably accounts for a decent amount of the total weight.

Recoil is not an issue if you’re building a .22. And you might want a lighter lower to go with an ultralight upper, like e.g. what TACCOM does:

http://www.taccom3g.com/ultralight-17–upper.html

As for polymer FCG, there are many guns on the market by now that have it at least in part, and the sky didn’t fall. For example, Beretta CX4 has a polymer hammer and trigger; how many of those have had issues?

Jeremy –

Can an aftermarket group like a Timney be dropped in?

Yeah, as a stripped lower it’s dimensionally in-spec and everything seems to work fine. I tried a couple drop-in triggers, a different grip, a different safety, etc… no issues. The only note (it’s in the review, too, btw) is that the polymer safety bar is specific to the polymer trigger group. It won’t work with a normal trigger group and a normal trigger group won’t work with it…

I’m glad you mention that a standard AR-15 trigger is compatible with some fitting, but what about buffer tube accessories? Like stocks and spring kits like the JP one you reviewed.

I feel pretty good about polymer (done right) being strong enough for rifle handling. If I trusted the company I don’t think it would crack or bend in normal use. Reference the PMAG of today, at least as durable as an aluminum (USGI-type) magazine. But what concerns me about using receivers (upper, lower, or both) of a material weaker than aluminum (per volume, at least) is the suitability to protect the shooter in the event of a catastrophic ammunition failure. If we have a cartridge blow up in the action in a particularly unlucky way, and it does happen from time to time, the receiver needs to be strong enough to not rupture and cause harm to the shooter. I want the blast to go right down through the magazine well, probably blowing the magazine or the magazine base plate right out of the rifle, because the receiver is strong. In such a case I’d expect rifle damage, and that’s to be expected. I’m OK if the receiver is then unusable. I just don’t want to compromise strength in a way that increases the risk of a rifle blowing up in my face and injuring me. This sort of robust design is typically never needed in the life of a rifle, as with modern factory ammo these failures are rare (more common with handloads and old foreign military surplus ammunition, of course) but one doesn’t want to lose this protection because in the case of an ammunition error (by shooter, ammunition loader, or just bad luck) it is really important to keep the shooter safe. It’s not just polymer, I’ve read a handful of reports of people concerned with the strength of receivers made from other materials (like the aluminum-magnesium MAG Tactical Systems AIR-15) after “kabooms” that gave me pause. I think there’s a thread on AR-15.com with photos of an AIR-15 not holding up well in comparison to an aluminum receiver after an explosive ammunition failure. I’m on the fence, but I’m currently still favoring the relatively lightweight aluminum receivers that are simply milled cleverly to cut weight. I am very tempted to reduce weight any way I can, as long as I’m confident I’m not sacrificing utility and safety.

“I’m glad you mention that a standard AR-15 trigger is compatible with some fitting, but what about buffer tube accessories? Like stocks and spring kits like the JP one you reviewed.”

No fitting should be needed if you use a standard safety as well. The plastic buffer tube on this thing is commercial spec so you could swap a different stock onto it or use whatever carbine-length buffer weight & spring you wanted to, but the plastic buffer tube is probably my least favorite part of the assembled lower. Any standard buffer tube will fit the receiver, so any stock option is available. Bottom line is that the stripped lower receiver is totally standard in every parts-related dimension so any standard, “mil-spec” parts kit part or aftermarket part designed to replace those “mil-spec” parts is going to fit properly.

I’ve definitely seen tons of photos with the sides blown off an AR-15 upper due to a “kaboom,” and a few with one of the sides of the magwell cracked off or just noticeably warped/cracked. The magwell offers a lot of volume and space for the gas to exit when the mag gets blown out, and I’m not sure I’ve seen a photo where damage to the lower occurs rearwards of the magwell? Definitely a lot of them showing why it’s not entirely safe to grip the gun there, though! At any rate, the bolt is usually forwards if not entirely in battery still and the chamber and side of the bolt explodes, ripping off one or both sides of the upper but keeping most of that carnage in front of the lower receiver. It just isn’t exposed to that much of the escaping gas, pressure, and shrapnel, and what it does get is at the front of the magwell. Thankfully, your strong hand is on the pistol grip a decent distance and a lot of material away from that. Much more protected than w/ a handgun. I think the AR injuries I’ve seen were the support hand and/or arm being injured by parts of the upper exploding…

Thanks for the clarifications about the buffer tube and standard dimensions of the receiver, Jeremy. I agree that the strength of the upper receiver is even more concerning, but our forearms are still by the magwell when we shoot and sometimes our hands touching on the magazine, especially when shooting off a bench. I might be willing to keep an extra ounce or two (with a lightweight metal receiver) if I thought there was a greater margin of safety in case of major stress on the receiver caused by a round going off out of battery.

Besides the aforementioned aluminum-magnesium alloy MAG Tactical Systems AIR-15, other notable lightweight AR-15 recievers include the 2A Armament BALIOS-Lite, the BAD556-LW, and the V Seven (V7) M4, all of which are 7075 T6 aluminum, and other polymer recievers like the Robar PolymAR-15. I’m not going to include figures here because the manufacturers don’t all provide apples-to-apples weight figures to compare, but going off of manufacturer-provided numbers the weight differences to the StarLos SLF-15 come down to about an ounce or two.

I absolutely love that trigger guard on the StarLos SLF-15 lower, it looks fantastic for use in temperatures below freezing while wearing thicker gloves. Generally, the more space in front of the trigger bow I have for a thick gloved finger the happier I am, as it’s less of a limiting factor in very cold environments.

Honestly, I think it’s a leap to assume that any of the other lightweight receivers you mentioned are stronger or otherwise more likely to protect you from a kaboom than this one. For all I know, this one would provide significantly more protection. Or maybe lots less. Or maybe the same. Really no way to know without in-depth testing. …Maybe it’ll flex and allow the mag to pop out more easily, venting the gas pressure faster, without cracking or breaking, whereas the more brittle nature of the other materials means it simply fractures and becomes shrapnel. Flexing or no flexing, it’s possible that it can handle more, not less, force before failure.

I have no idea how much of this is marketing BS and how much is true or how it specifically applies to this lower vs. an aluminum lower, but StarLos does have a spiel around strength on its website in the “technology” section. Here’s some of it:

You should take a look at Tn arms co. polymer lower. They use a hybrid nylon/polymer that flexes and returns to shape. They shoot .50BMG on them too haha

I Bought this lower, Slapped on an AR Stoner upper from Midway. Took it out to the range for a sight in of the MBUS rear sight I added. Inserted a 30rd PMAG, pulled the trigger, Bang!. Pulled the trigger 5 more times, bang, bang ,bang, bang, bang! Ok cool..so I did a double tap…BangBang! then the next round, click!

Extracted the round to see a very light primer strike.

Performed the above again with the same results. In fact any rapid fire would result in a failure to fire.

Pissed, took it home and put it on the bench. REMOVED plastic FCG and inserted a spare metal trigger, disconnector, hammer, all with new heavy springs. (The springs for the plastic junk FCG were very light and hammer spring was already distorted. )

Took it to the range again and it ran 200% better. But still had one failure to fire after a rapid fire session. Noticed that it was due to the bolt not going fully into battery. Ordering a metal buffer tube with standard spring and throwing away the piece of crap plastic one with light spring.

As soon as this thing runs perfectly, it will be for sale. …

this review is not the truth. Oh and try to find a website or facebook page for starlos. looks like they are already out of business. lifetime warranty my ass…

hmiddleu cialis without prescription gsupposedn cialis without prescription

ausualf http://tadalafed.com

cialis professional online

dthemo http://tadalafed.com

gthreej antidepressants for sleep paxil pills

10 most popular antidepressants

uperfectlyv wellbutrin

ftdzCU56MO8 Praesentium eum eos impedit rerum occaecati.

Rem

rmann9vcT Tempora quasi illo aperiam ex. Molestiae incidunt

fQkyS3XV Corporis molestiae quos commodi reiciendis error.

ZHIgxNoTGe5s Ratione minus cumque soluta eos. Nemo velit praes

WHd7W45UJ43p Harum pariatur quae accusamus iure impedit. Corpo

8w6qqaDa88i Beha TSrCmHBPxMUcieMuw3JY

DtYyCpaFdO Half 91BFIkHOjyCyqtunZhJe

Removing some of your upper cabinetry can completely transform your kitchen. It’ll feel lighter, more modern and perhaps even more functional. Open shelving is a great way to display stacks of the everyday dishes you use along with items like cookbooks, serving platters and fresh herbs. It’s actually more convenient for grabbing and putting away dishes where they belong. If your cabinets are built-ins, adding feet to your kitchen cabinets will create a freestanding look without a total remodel. Different foot styles are common with different design trends, so you can tailor this kitchen cabinet upgrade to the specific style you’re looking for. Try bun feet and turned legs for a classic kitchen design. Elevate your base cabinets with tapered feet for Modern kitchens, or keep your design Contemporary and install metal feet on your cabinets. Plus, doing it yourself only takes a few steps! http://blogforum.kasipkor.kz/kz/community/profile/jess04x69390579/ HomeAdvisor puts the average kitchen remodel price in the $12,567 to $34,962 range. A small kitchen remodel can cost as little as $4,000 and a lavish remodel can cost as much as $50,000+. The average cost of kitchen remodeling for your average-sized kitchen will be over $20,000. The final cost will depend on the size of your kitchen as well as how luxurious cabinets or appliances you want to install. A major kitchen renovation may cost you anywhere between $40,000 to $70,000. Admit it. Every time you watch Gordon Ramsay, Paula Deen, Rachael Ray and Tom Colicchio whip up delicious food on YouTube, you pay as much attention to the color of the kitchen cabinet and its simple-yet-aesthetic appeal as to the amount of salt that is added. But the task of remodeling your kitchen remains a mere footnote in the long list of things you need to do. Worry not. Here’s your step-by-step guide to what you need to spend on, how much to spend on it, and how you can cut costs without lowering the quality of your remodeled kitchen.