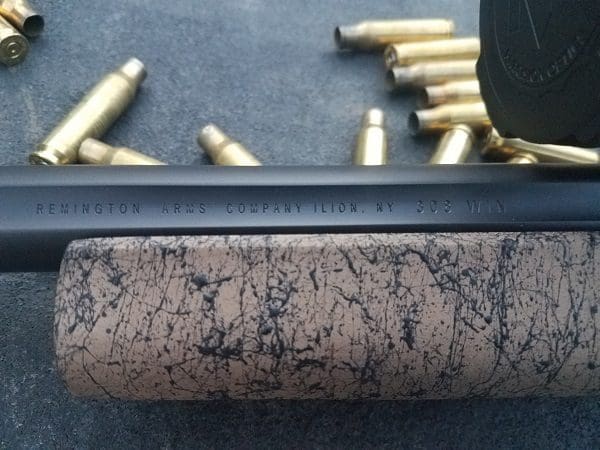

The Remington 700 5-R Stainless Threaded Gen 2 is one of the latest additions to their classic 700BDL hinged floor plate design. The short action rifle comes in two barrel lengths: 20″ and 24″. If you opt for the 24″ barrel, you can buy one chambered in 6.5 Creedmoor, .300 Win Mag and .308. The gun tested here, a 20″ version chambered in .308, could well be the Goldilocks gun.

At 8.5 lbs naked, our T&E 5-R Stainless wasn’t light. But at just under 40 inches of overall length long, it’s quite handy. The short, rigid barrel is maneuverable and, as we will see later, extremely accurate.

The 5-R Stainless Gen 2 comes threaded from the factory for a muffler; this rifle absolutely begs for one. In fact, even at first glance, you can see that suppressor-favoring tactical and competition shooters have influenced the firearm’s design. Remington’s taken cues from some of the most common and proven configurations of custom short action bolt guns and applied them here.

As the name implies, the 5-R rifling on the 20-inch stainless steel, hammer-forged barrel is one of the rifle’s major features. It stands apart from most modern barrels’ six lands configuration. First, there are . . . wait for it . . . five lands. They’re taper-cut at a 110-degree angle to the grooves (as opposed to the usual 90 degrees) and none of them directly oppose another land.

This design leads to longer barrel life, less fouling and more consistent shot strings over time. Well, that’s what a lot of shooters swear by, and what Remington claims.

After shooting 310 rounds through this rifle, I didn’t perceive any significant advantages over other quality barrels. That said, plenty of folks feed their bolt guns a whole lot more than rounds than that. They can go through two barrels or more a year. So 5-R-related barrel longevity could be a thing.

What I can confirm: this is the same rifling found on the U.S. Army’s M24 Sniper Weapon System. The Army’s testing protocol for these barrels is extremely rigorous; it’s the kind of testing that only gets done when Uncle Sugar is paying the bill.

The 5-R Stainless Gen 2 comes equipped with Remington’s X-Mark Pro trigger. I’ve seen this trigger on several post-2014 700s and shot them quite a bit. For a stock trigger, the X-Mark has a great feel: nice and crisp with no grit at all. In that sense, it’s just as good as most aftermarket triggers.

Unfortunately, the X-Mark Pro trigger’s externally adjustable screw is not my friend. If you back it out far enough to really lower the trigger’s pull weight, it sticks out too far and becomes uncomfortable. Worse, I’ve never found one that dials down far enough. The literature says the trigger adjusts down to 2 lbs, but I’ve never been able to get one below 3 lbs.

Some people remove the adjustment screw entirely and report no ill effects. I haven’t tried that, nor do I recommend it. As it is, I’d bet that most precision shooters will replace the stock X-Mark Pro trigger with an aftermarket drop-in trigger, as was done here. (A Timney trigger was the only modification from our test gun’s factory configuration.)

Remington should have set the 5-R Stainless Gen 2’s trigger at 2 lbs. This isn’t a hunting rifle. It’s a target and “tactical” rifle. A crisp 2 lb. trigger pull would be entirely appropriate and save customers the time and expense of fitting an aftermarket solution.

Remington made a great choice, though, in blessing the 700 5-R Stainless with an H-S Precision stock. H-S Precision has been the go-to stock for thousands of shooters over the years, and for good reason. (It’s also the stock of choice for the Army’s M24 rifle, although the 5-R Stainless doesn’t offer the Army stock’s adjustable length of pull.)

These stocks start with a CNC machined aluminum bedding block set into a Kevlar, fiberglass, and carbon fiber mold. They’re slightly wider than most sporting gun stocks. That wide, flat fore-end makes them right at home shooting from a bench rest or bags.

The 5-R Stainless Gen 2’s stock features dual front swivel studs (removed by the owner of our test gun), and an absolutely ideal ambidextrous palm swell for those of us who like to keep our thumb down for accuracy when shooting. There isn’t much of a recoil pad, but there really isn’t a need for one – although a recoil pad’s the easiest place someone like me with long arms can make some LOP adjustment.

The factory 13 3/8″ length of pull is a bit short for me, even wearing heavy winter clothes or a shooting jacket. For most folks under 6’2″, it should work well. The 5-R Stainless’s stock lacks an adjustable cheek riser; I had to lightly keep my check on the stock to be in the right position for the scope.

I like to let the weight of my head crush down on the stock for a solid cheek-stock weld. I consider my head properly positioned if I can nap on the gun without getting a crick in my neck. The 5-R Stainless’s cheek height is easily modified with a kitchen sponge and some duct tape; the fix for many a soldier’s rifle for decades. If you want something a little more elegant, I recommend either the Karsten Custom Cheek Rest or the Bradley Adjustable Cheek Rest.

Taken as a whole, the 700 5-R Stainless Gen 2 isn’t a bad looking gun, and very tame on the “tacticool” side. The H-S Precision stock sports what has become a classic sand a splash-web pattern, while the barrel and all other metal is Cerakoted a flat(ish) black. I’d actually prefer a flatter black than this, like the Armorer’s Black or Graphite Black, as there’s no need for gleam.

The 700 5-R Stainless Gen 2’s medium contour barrel sports six longitudinal flutes, reducing weight and adding surface area for cooling. The longest string I shot was 60 rounds. At the end I could still hold the barrel firmly without distress. The large, easy-to -find knurled bolt knob enabled rapid manipulation and added to the modern tactical rifle gestalt.

The venerable 700 action performs exceptionally well on this gun. There’s little to no play in bolt at the rear. Once you start it moving forward the bolt glides solidly on the rails until it locks home.

Bringing the bolt down on a round, I felt no hesitation or sticking. Just a smooth, fast operation all the way through the cycle. Sitting behind the gun, cycling the bolt and trigger as fast as I could while looking through the glass, I got nothing but a sure and confident feed.

Truth be told, I haven’t always been a fan of the Remington 700’s action, at least as compared to the Winchester Model 70. From a design standpoint, it’s just not as good as the Winchester’s improved Mauser action. But for what it is — a push feed design — this gun performs exceptionally well. If I’m getting a fast, smooth action with a great lock-up and sure extraction, I’m not asking for anything more.

I didn’t have any issues with loading, unloading, cycling or firing this gun. The data book that came with the Remington 700 5-R Stainless revealed that someone had put over 600 rounds through it. As I mentioned, I put another 310 down range. Neither my experience, nor the data book recorded any malfunctions of any kind across multiple types of rounds from multiple manufacturers, in a fairly wide weight range.

I shot rounds from Fiocchi, Remington, Hornady, and Federal in weights from 125gr to the exceptionally well performing 185gr OTM Juggernaut. All performed smoothly. I’ve had problems with other bolt-action rifles: sticky bolts or the magazine follower getting hung up. Not here.

But in the words of HughTazmanian Devil, “blah blah blah, yakety schmackety.” None of that matters in the least if the gun won’t print tiny groups. And this gun prints tiny groups.

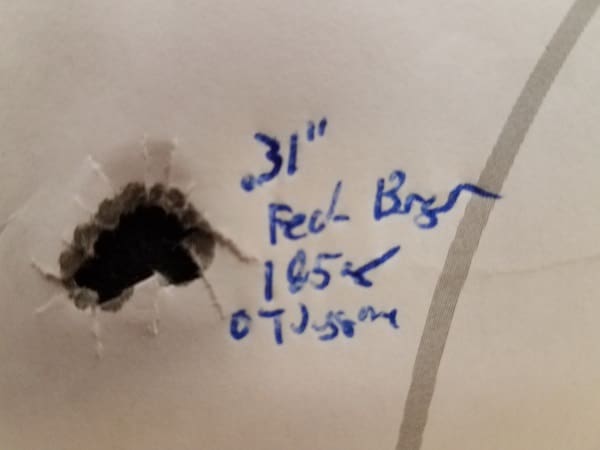

I had this gun for far longer than I should have. That’s because none of the shooting was just done for “fam fire“. For this review, after using 10 of the Fiocchi rounds to dirty the bore, I shot 50 un-timed five-round groups. None of the groups shot by the 5-R Stainless were bad, but some were much, much better than others.

The “worst”-shooting round was, oddly enough, the Remington 150gr CoreLokt bullet, right at 1MOA. The Federal 150gr “Non Typical Whitetail” soft point scored 3/4-inch groups, on average. Things got much better once the bullet weights increased.

The Federal 168gr Sierra Match King scored .51-inch. Hornady 168gr AMax Black round printed .37-inch and the 185gr Federal Gold Medal Berger 185gr OTM Juggernaught rounds scored a truly impressive .31″ average group. I shot the rounds off bags at 100 yards. I shot each 20-round box in four strings of five rounds. I finished by shooting 10 rounds from the kneel and 10 rounds standing with Hornady’s 125gr Custom Lite SST loads.

These results are from a factory rifle, shooting multiple factory rounds, achieving 1/2 MOA or better. I’ve hammered Big Green in the past for their lack of quality control. But the gunmaker is right on point with the 5-R Stainless Gen 2.

To see if this particular rifle was the proverbial “blind squirrel finding a nut” I asked around on a few forums. Shooters reported that our test 5-R Stainless’s level of accuracy holds across numerous examples. That makes the 5-R the best bang for the buck, accuracy wise, of any rifle I’ve fired in a long time. Maybe ever.

I make it a point to not check prices until the end of a review, and given its performance, I was expecting this rifle to have a custom shop price tag. Imagine my surprise to find an MSRP of $1,250 and availability online for $100 to $200 less.

If I was going to go out and buy an all-around bolt action rifle — one I could compete with, target shoot with and even hunt with — this gun would be extremely hard to beat. In fact, this is the gun that made me fall in love with Big Green, again.

I got this gun just before I wrote my review of the 700 American Wilderness. While both rifles are Remington 700’s, they couldn’t be farther apart in quality. Everything about the 5-R Stainless was done right: good components, great execution. It left me wondering how these two rifles are made by the same company.

While it’s not my place to tell gun companies how to run their businesses, Remington should find the people who designed and produced the Remington 700 5-R Stainless and put them in charge of all 700 production.

SPECIFICATIONS: Remington 700 5-R Stainless Threaded Gen 2

Caliber: .308 Win

Order No: 85196

Magazine Capacity: 4

Barrel Length: 20 inches

Twist: 1:11-1/4 RH

Overall Length: 39 3/4″

Length of Pull: 13 3/8″

Drop at Comb: 1 1/4″

Drop at Heel: 1 1/2″

Barrel Material: Stainless Steel

Barrel Finish: Black Cerakote

Stock: H-S Precision Stock

Stock Finish: Sand Color with Black Webbing

Weight: 8.5 lbs

MSRP: $1,250 (found online for $100-$200 less)

RATINGS (out of five stars):

Style and Appearance * * * *

A bit on the tactical side, but well done. Black Cerakote over stainless steel is a durable, good looking combination. No fancy wood, no fancy anything, but a great “working” gun. A working man’s gun, a shooter’s gun, and one I wouldn’t mind throwing up on the hood for a shot a wild ram in West Texas.

Ergonomics * * * *

The H-S Precision stock is well made and performs extremely well. One star off for no length of pull or cheek riser adjustment, but that’s easily and relatively cheaply remedied without a gunsmith.

Customize This * * * * *

Remington has done most of the work for you. Then again it would be hard to argue that any other bolt action rifle on the planet has more aftermarket parts available than the Remington 700BDL.

Reliability * * * * *

Perfect across lots of rounds of different types and weights. No sticky bolts and no discernible loss of accuracy across the entire 310-round string.

Accuracy * * * * *

This is where it counts and Remington absolutely nailed it. Multiple brands and weights hit the 1/2 MOA mark from a factory gun with factory ammunition. I have no doubt a pet load would get you to the 1/4 MOA range.

Overall * * * * 1/2

The lack of an out-of-the-box lightweight (2lbs or less) trigger and the static LOP keeps this gun just out of the 5 star category. Otherwise, the Remington 700 5-R Stainless Threaded Gen 2 performs well above its price range. I’ve started wearing my old “Remington Defense” T-shirt again.

The stock has that nice finish reminiscent of cheap Chinese furniture.

“… nice finish reminiscent of cheap Chinese furniture.”

No, it has a finish like the interior of sweet little Kevlar-hulled ‘flats’ boat I built in the 90’s.

The ‘splatter’ finish works quite well for vastly improving grip, pretty much everywhere on the stock you happen to grab it.

Consider it a quick-n-dirty checkering job…

Typo alert, ” Hornady 150gr “Non Typical Whitetail” Hornady should be Federal.

Fixed, thanks.

If you don’t mind my asking, did you get the barrel you wanted for your Ruger #1 build?

Still can’t find anyone I’d trust that will do a octagonal to round. I’m going with a 26″ custom PacNor instead, and they are taking a full 12 weeks to make it. Still waiting.

Good choice going PacNor. I think you’ll like the results.

.31 MOA from a thousand dollar .308 rifle?

thats pretty sweet

$1,250? Hopefully Remington’s quality is back in their rifles.

While i like the stock ,i paid less for 2 savage model 10’s, a 10t and a 10fcp-sr.

Both shoot half inch groups for half the price, both have 5R rifling, and both are magazine fed.

Savage has always made a great gun at a great price.

Savage barrels are incredible.

Im very curious about the quality of this rifle as i like the 700 action as well, but have ben less than impressed with the 700s ive seen at the local gun stores and the other 700 in 30-06 that was reviewed here recently.

If they are on their way back up, i would definitely consider one of these as my next tackdriver.

I came here to say the same thing about the 10 fcp-sr. Picked one up earlier this year when Savage was offering a $100 rebate. I absolutely love it and the thing is a tack-driver, even shooting steel-cased Monarch. The 10 is the best out of the box bolt action rifle for under a grande.

The mag that it comes with could be better though…

It goes for $820 on Buds: https://www.budsgunshop.com/catalog/product_info.php/products_id/42391/Remington+Firearms+29663+700+5-R+Bolt+308+Winchester%2F7.62+NATO+24+4%2B1+Syntheti

I picked up my copy of the 700 5-R for $999 locally. NIB.

I had been looking at some Savages and after upgrading the Savage base models to address some reviewers’ notes (stocks, etc.), the M700 was the better deal.

Sounds fairly good, how about compared to the Ruger Precision?

Hmm.

.31 inches. Without tinkering. That’s damn good.

A few people online told me they got to 1/4MOA with the heavier commercial rounds. I didn’t quite see that level of precision with any factory ammunition, but anything in the .3s is darn good.

How does a man misspell his own name? 😀

Shit, that’s a full .1″ better than my handloads with the Juggernauts out of a Remington VLS, that’s pretty impressive.

I really like the bolt handle they are putting on some of their “tactical” rifles now, reminds me of the Stiller Tac-30/300 customs actions that cost as much as this entire gun.

I may be buying one of these in the near future.

I’m gonna sound like an ass, but my question is serious…

Every time I hear someone talking about getting a 1/4″ group from a .30 caliber, I have to ask, “How can you get a 1/4″ hole from something that’s already 5/16″? It’s physically impossible to get something smaller from something larger– unless it’s a pie and you’re cutting it into wedges.

Seriously, how can I get 1/4” groups from my .308? At the moment, I’m cutting them to 3/8 and think that’s more than wonderful. Please, give me guidance.

It’s common practice to measure groups from centers of the most distant bullet holes. Hope that clarifies it for you.

You measure the group from farthest outside edge to farthest outside edge and the deduct the diameter of the bullet.

jimmy james gives one way, and a good one, another way is edge to edge, but ORCON is noting how I and most other folks do it, center to center.

Maybe in ten – fifteen years I’ll consider looking at Remington again, if they can get a handle on their QC. There are too many other options out there than to consider a gun made by a company with a poor reputation.

Sadly, that’s about it for me too. Their handling of the 700 safety issue also pretty much guarantees I’ll never have one of that particular model.

I can understand y’all’s caution buying R again…I’m the same way. To be fair though, two of my friends have bought 700s within the last year or two and they have performed flawlessly.

5R rifling cleans more easily, but can be easily damaged by cleaning rods. The Russians played with it in WWII. In the US, it was made popular by Boots Obermeyer, of benchrest barrel production fame. You used to have to order 5R barrels from Boots alone, but now there are several custom barrel shops offering cut rifling 5R barrels in various configurations. You can get 5R barrels from Krieger, Bartlein, etc. today.

5R barrels have been used in the benchrest community for decades. Obermeyer developed the 5R rifling scheme to:

1. Reduce powder fouling in the corners of the cut grooves. 5R (real 5R) barrels don’t have a rifling groove that looks like this: |_|. The 5R groove profile is more like this: \_/ , which Obermeyer said led to reduced jacket failures, easier cleaning, etc.

2. However, because there is a narrower land “peak” , you should be more careful cleaning the barrel. Don’t use those stupid segmented cleaning rods that the military uses. Use a quality, one-piece cleaning rod, preferably made from good stainless steel, that is wiped down every time you put it down the bore. Use a rod guide.

Now, as to issue of barrel life: that will depend upon the loads being put through it, and how careful the shooter is in cleaning it. Plenty of rifle barrels are ruined by people who don’t give a rat’s rear end for proper handling of a cleaning rod, or they use those POS segmented military cleaning rods, etc. The other thing that affects barrels rapidly are those people who just can’t bring themselves to lo shoot modest pressure/velocity loads. There are some people who have as their only criteria for their reloads “Faster!,” their starting point is the “max load” column in a reloading manual, and they shove more and more double-base powder into a cartridge to maximize velocity, which will minimize barrel life, which leads to burning up the throat in the barrel – sometimes in as little as 800 rounds for the people who load really hot cartridges, especially those cartridges that are overbore.

5R barrels haven’t been found “more precise” (or “accurate” in the common lingo), but they are easier to clean completely, and they result in fewer jacket failures. Since BR shooters are usually quite fastidious about cleaning, anything that makes cleaning easier gets some attention. You can still shoot tight groups with a 4 groove, 6 groove, or even a 2-groove barrel. I have no problems shooting nice groups (a tad more than MOA) with factory-issue 2 groove 1903A3’s when I load them with high quality bullets, modest loads and I do my part. Remington found during WWII that their 2-groove barrels were slightly more precise (accurate) than the 1903’s 4-groove barrels.

Being that this barrel is hammer-forged, it probably won’t compete in BR and F-class with a single-point cut rifle barrel (5R or otherwise), but this is a pretty nice result for a factory rifle that could be made even nicer with reloading with high quality bullets. That said, the thread protector on this looks like crap, and from what I’ve seen, this is a spray-on/bake-on paint finish.

None of this 5R stuff is a secret to those who have been paying attention to the OFWG’s in the benchrest community for, oh, the last 40 years.

Still boycotting H S Precision. So, no dice on the Remington.

Note: One would expect TTAG to know about this stuff.

One knows, thinks it’s ridiculous, and does not care. One also shoots a Mosin Nagant made by the Soviets, and a K98 made by the Nazis.

I picked up an unfired 700 5R produced in 2002 for $875. Only thing I did was have the muzzle threaded and brake installed. I’m a notoriously poor shooter and even I can shoot 1/2 MOA with handloads. To quote a friend, My Rem 5R is my “cheat machine.” Incredible rifles.

I’m not terribly surprised.

My 20″ 700 SPS in .243 has proved itself to be a reliable and damn accurate rifle.

I didn’t like the stock, so I swapped to a MacMillan A5, but other than that I’ve loved it.

HS precision stock? Is this thing lon horiuchi-endorsed?

On top of their numerous quality control fuck ups, big green now sources stocks from a company that knowingly hired a cold blooded murderer…….yay remington…….

First: Yes, HS Precision is the company that was endorsed by Lon Horiuchi

Second: Remington has been putting HS Precision Stocks on some of their nicest 700’s for a few decades (original Sendero, Sendero SF, Sendero SFII, VSF, VSSFII, original 5r, 5r gen2, 700p, 700 LTR… maybe a few others?).

I can’t remember the details but an etailer was selling the gen 1 5R’s at a heck of a discount and there was a pretty good rebate from Remy. I think the final cost was in the $650 range. Those guns were going for $1200 a couple years ago if you could find one. I have a couple shooting buddies with gen 1 5R’s and they are very accurate but not as accurate as that 0.31″ group. That is outstanding. I would order 500 of those bullets not load anything else.

After rebate you can get a Savage Stealth in .308 or 6.5 Creedmoor for about $750. So thanks Remington, but no thanks. Especially after the last rifle review I read on here with a Remington. I’m still not happy with how much of a POS my 870 was.

It is a pity that it’s not possible to install a cheek riser on this stock, it is very handy when using optics.

Does anyone know a reputable online store where one of these rifles can be purchased?

The Exchange at http://www.onlinegundeals.com is one of my go to online dealers.

Also, Buds Gun Shop at https://www.budsgunshop.com is great.

Lastly, Gun.Deals at https://gun.deals will let you search for what you want and give you all dealers and their prices.

I am a Canadian and bought a Remington 700 SS 5R in a .300 Win Mag.. after waiting to receive the rifle over several months it finally arrived. I invested close to $2000 in a Vortex Viper PST Gen II, first shot I fired, the rifle jammed…. it took a lot of force to eject the empty and subsequent shots lead to the same result..

The rifle was sent back to the Master Distributor in Canada who diagnosed the rifle with a “mis-cut Head space”. The rifle was declared “scrapped” and Remington was supposed to replace the weapon. its now been several months that the new rifle is awaited.. I have been requesting and writing to Remington but to no avail. My trust in the Remington name is greatly shaken.

Will someone in Remington pay heed to a Customer????

I still love my Remington 700 .308. I do however have plenty of issues with their customer service. I purchased my newest about 8 maths ago and it is the 700 tactical. I am a sucker for the heavy barrels. I noticed it started to have a orange haze the first day. I of course oiled it and thought nothing else of it. Woke up to a even darker orange color. I observed the online forums staying issues with the finish on these rifles and decided to email customer support at big green. They replied with one email saying I could send it to someone locally (at my cost to have it looked at) and that was it. I emailed them back saying I shouldn’t have to worry about my new 700$ rifle rusting with delicate care that it was a issue from the factory and I wanted to return it and they just never responded back. Never even after 3 more emails . So I have to oil every night and I’ve tried all different approaches. It’s a poor poor finish. The poorest.

I have been shooting HS Precision stocked rifles in the LTR and PSS Model 700 variety for many years and if you skim bed the actions on top of the aluminum bedding blocks they will shoot crazy small groups.

Otherwise the torque on the action screws becomes an issue and although groups may be small they can shift from shooting session to shooting session and are more susceptible to differences in shooting style, type of rest, etc.

I also use Timney or Jewell triggers because Remington triggers suck but otherwise their quality in their premium rifles has taken a positive jump upwards in the last few years in my experience.

Old thread, but my five-year old 5R in .308with the 20 inch barrel threaded has always been a stellar performer. I’m at 500 rounds and counting logged; groups run <1/2 with Federal match; Winchester and Blackhills do the same, or a tiny bit better running the stock trigger. But stoked with 168 Matchkings over 4X something of 4064, the gun is a different beast. Groups down in the .3 range. Great for me. Stuffed with the beautifully long 165 grain hollow point pro hunter and it runs the same .3….. that's a bullet you could use on about anything in NA. The only stock rifle I've owned to beat this 5R is a Steyr SSG 69. I stuffed it into a HS Precision stock on day 1; never looked back.

Great review. I have a couple of thoughts to add to yours:

1. There are only 3 flutes on the barrel. Flutes are the groves. I know even the Remington web site says 6.

2. I’ve had good luck removing the trigger adjustment screw on my Remington triggers. The problem w/ the set up is that as you back out the screw to lower the trigger pull, the screw head is exposed and as you pull the trigger, it rubs on your finger and is distracting. After 100s of rounds through 2 other rifles, I have seen no ill effects, NDs, or any other problems.

3. I have the same gun in 6.5 Creedmore. It’s shoots 5 shot groups at 0.8MOA using various factory match loads, which is similar to the experience I’ve had w/ my 3 other 700s in (308, 243, and 22-250). I didn’t find the 5r barrel to be especially more accurate or easier to clean, but over all am very happy w/ the gun.

What scope rings did you use?

Gear up as your favorite Delsin Rowe Vest. Slim Fit Leather Jackets brings this iconic jacket from animation to reality, especially for all the fans of this video game. Delsin Rowe is the main protagonist and playable character, a young Native-American man who later realizes he’s a Conduit with special powers.