If you read part one of this review, you know that the good folks at Cabot Guns made good and quick-like on their promise to return the Cabot Black Diamond that I sent back to them. To recap: pretty gun, lots of first-round failures to feed. But I was more than happy to try it out again. There are a lot of great guns that won’t run well out of the box, they take 500 rounds or so. That’s not limited to 1911s, either. It’s true of a lot of very tight, very accurate guns . . .

Some companies take this to the extreme. My Les Baers have all been the most accurate guns I’ve owned. My starter Les Baer Premier will shoot smaller groups than any Wilson Combat or Ed Brown I ever owned or ran it against…for about 50 rounds. Then I had to lube it up again to get it to run at all. Les Baer shooters tell me that will go away after a few thousand more rounds — like about 7,000 more. Negative Ghost Rider, the pattern is full.

As Cabot’s guns are all super precision-made and all, I convinced myself that this gun was like the Les Baers. Which, by the way, if that’s true, I would appreciate it if the manufacturer would send me the gun after they’ve put the required number of break-in rounds through it. But if it means putting a few hundred rounds through the Black Diamond, well, I’ve got rounds, I got the Cabot, and I’m drowning in RemOil.

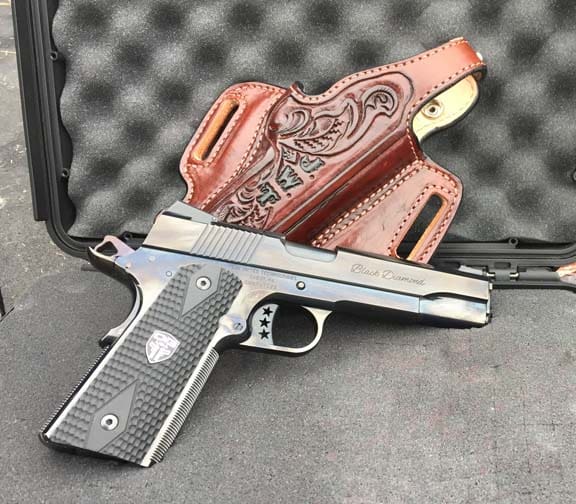

I picked the returned gun up and opened the box. Cabot cleaned it up nicely after I sent it back to them and I was once again surprised at just how good this gun looked, and I was stoked to get it out to the range. As they suggested that I not use the CORBON Performance Match ammunition that I used last time, I used Winchester white box 230gr FMJ for this test. It’s filthy ammo, but it’s my preferred range brass and I don’t think there is a more ubiquitous round out there.

As an aside, unless it was issued to me, it is a very rare thing for me to give a gun a second try. There are just too many great guns out there to waste my time. But man, this guns is pretty. And when it ran, it ran fast and returned to the target quickly. So…pretty, fast, black, and it feels real good in my hands. Oh…right. That’s why I’m giving it another try. I think we might have dated in college.

To the range!

I loaded up the supplied Cabot magazine, and let the slide come forward. And it did. Fully, right into battery. Success! I told you we should be together.

Six rounds. The gun made it six rounds until the first failure to feed.

After that, it was a rare thing to go more than two magazine without a failure to feed. RemOil did not fix the problem. A bore snake did not fix the problem. Q-tips did not fix the problem. I tried the Winchester white box as well as the CORBON again, along with some American Eagle 230gr FMJs, Federal Hydra Shock, and some hand loads. No factory round made it through two magazines without a first-round failure to feed or without fully returning to battery.

The only thing that made it without a failure were hand loaded 200gr Hornady XTP rounds loaded with seven grains of Clays Universal with a C.O.L. of 1.23. The gun ran very well like this and I brought the groups down to an average group size of 1.75″ with a best group of 1.25″.

After that, my opinion of the pistol remained the same.

Gorgeous. Unreliable. (Yeah, we must have dated.)

I gave the gun back to Mr. Farago and called it a day. I have to say, I was pretty disappointed. I was looking forward to ordering one and had already picked out some Desert Ironwood grips and Heine Straight 8’s for it. But a 1911 that won’t run most ammunition isn’t for me.

Then a conversation with Cabot about the ammunition they try and what they like got me thinking. I called Farago back and asked if I could have yet another try at the gun. I went to my reloading bench and took all those same factory FMJ bullets and seated them to 1.23. I had a lot of hypotheses about why this would work. My hypotheses made sense.

And they were all wrong. Round three had similar results. When the gun ran, it ran great. The rounds went where I wanted them to go, and the gun timed itself well. The front site returned to the target just before I wanted to squeeze off another round, and landed right there, eager and ready for more.

Except when it didn’t. And it didn’t a lot.

Specifications: Cabot Guns Black Diamond

Barrel: 5-inch national match grade fitted barrel

Steel: USA 4140 sourced billet, proprietary hardening, hand polished

Finish: Black blued

Safety: Right hand thumb, optional abidextrous

Sights: Low mount adjustable rear two-dot tritium, Rozic front blind sight with tritium dot

Grips: G-10

MSRP: $5,950

Ratings (out of five stars):

Style * * * * *

The finish is perfect. Photos don’t do it justice. The lines are flawless. The flattened and serrated slide is executed beautifully and it actually has style. This isn’t just a shiny Colt clone.

Ergonomics * * * * 1/2

This is where JMB’s design shines. In Cabot’s version, the gun points well, the trigger well is a reasonable size, and the magazine release is right where it should be without being giant or in the way. The shooting hand rides nice and high on the grip, without pain or pinch during recoil. I took half a star off because I like a wider safety. But unless I am engaging it, my thumb never leaves the top of the safety, so that’s probably a personal preference. The trigger is crisp, and just light enough for a carry gun. And I carry I 1911 partially because they conceal so easily. Even this full-size Government hides in an El Paso Saddlery IWB holster under just a T-shirt.

Accuracy * * * *

With hand loads, this gun is plenty accurate, even at this price point. But with most factory loads I’d cut a star off. I’d like to see it printing 1.25 with quality factory ammo.

Reliability

It’s not.

Overall * * *

An exceptionally beautiful piece of craftsmanship that, sadly, wouldn’t run reliably.

After reading the review, Cabot president Rob Bianchin sends the following:

The Black Diamond is constructed to extreme tolerances equal to a fraction of a human hair. It’s a precision instrument and quality ammo is recommended for reliability and performance. The photo below compares the Corbon used in the TTAG review with some other brands. The bullets in the Corbon are seated very deep into the casing and we have historically seen dimensional variation outside the SAAMI standards with the Winchester white box. Neither ammo is recommended. Using low tolerance ammo in a high tolerance pistol is akin to using low quality fuel in a Ferrari. The Black Diamond 1911 employed in the TTAG review was tested with a mix of good quality ammo such as ASYM Precision Ammunition 185 JHP, Hornady 230 FMJ and Federal 230 JHP and did not skip a beat. The pistol was then further tested with these along with TUL, Armscor, Magtech and Wolf and the performance was flawless. Everyone should know and trust your ammo as much as your gun.

Cabot does take TTAGs results to heart and and will consider these results in particular with respect to our new S-Class line which will be announced shortly. The S-Class is priced in the $3800 range and may be subjected to many more brands of ammo, both good and poor. For the shooter looking for a precision gun made from the ground-up at a favorable price, the S-Class is the choice. For those seeking the ultimate precision built pistol, the Cabot Black Diamond and other Collector grade C-Class Cabot pistols will work reliably with recommended ammo. We guarantee it.

1/29/15 update from Rob Bianchin:

Cabot prides itself in making the finest pistols money can buy. No one is perfect but we do strive for perfection but once a while a ghost appears such as feed issue experienced by the reviewer of the Black Diamond. The issue was unexpected as prior to sending the gun to TTAG, the Black Diamond was shot by two individuals using five types of ammunition and it ran flawlessly. Cabot customers know our guns are both reliable and accurate. Just this week – January 27, 2015 -I received the following email from a client who works in a tactical capacity received his Cabot 1911 a few months ago.

“I just wanted to touch bases with you to say just how much I have loved my 1911 Southpaw. The guys on my team always fawn over it and I’ve actually been lectured that it is “too beautiful to shoot, let alone to carry everyday”. But carry it and shoot it I do! It’s a true nail-driver. It is also the first 1911 I have ever owned that will cycle any .45 ACP ammo. I know this because one day I tried 16 different brands, loads and bullet configurations. Including this “test” and the more than 2,500+ rds I’ve fired through it, I have yet to experience a stoppage (not counting training stoppages using dummy rounds). When I’m not on the range I have it loaded with jacketed hollow points per department policy. I’m very proud of my Cabot pistol and its unparalleled accuracy makes me confident that should the need arise, I can take that high risk shot with confidence. This pistol just gets better each time I shoot it…which is at least weekly.” Maj. Jon Irelan

Since the return of the Black Diamond tested by TTAG we made little changes to CGXPUT122. They consisted of adjusting (reducing) extractor tension a couple of ounces, repolished the breach face & feed ramp and increased the radius size on the barrel and frame to allow for lower tolerance ammo. We shot 300 rounds over the past weekend and did have two first round magazine related failure to feeds. The magazine in question was a flush bottom magazine that fits eight rounds but has spring pressure suited to 7 rounds. When the magazine was reviewed it had a full length spring and we switched it for one that was one wrap short with reduced spring pressure suited to 8 rounds and it worked fine. Standard 8 round non-flush bottom magazines do not have this issue. On Monday an additional 150 rounds were shot through a decelerator and had one failure to feed when it rubbed the slide against the rubber boot when shooting (testers’ fault). Later on Monday the gun was shot again again outdoors and we shot 28 magazines (228 rounds) without one failure.

The was the ammo that was used outside consisted of:

Corbon FMJ…4, 8 round magazines no failures

Wolf FMJ…4, 8 round magazines, no failures

Remington JHP…4, 8 round magazines, no failures

Armscor FMJ…4, 8 round magazines, no failures

Magtech FMJ…4, 8 round magazines, no failures

Hornady JHP…2, 8 round magazines & 1, 4 round magazine, no failures

PUT Reloads SWC…6, 8 round magazines, no failuresWe will be shooting it again later today.

We are inviting TTAG to visit and tour the manufacturing facility where the Black Diamond was constructed to see first hand the quality and precision which characterizes each Cabot pistol.

I would much rather have 40 hi-points.

10 CZ 75s.

Or if the insane accuracy is a must-have 3 CZ 75 Accu-shadows.

Go figure – my Hi-Point C9 loves WWB, I have 534 rounds fired for 9 minor stoppages. Wolf, Magtech, Freedom Munitions fmj & Hornady XTP jhp..

Now that’s just a crying shame.

“Six rounds. The gun made it six rounds until the first failure to feed.”

JUNK.

6k for a gun that won’t run and people say hi points are junk. Go figure.

Both are junk. But this is indeed worse, because at least with a high point you didn’t just blow enough money to buy a good used car.

…and I suspect the High Point actually works better.

The people at Cabot should be ashamed of themselves. If they aren’t, that’s even worse.

If you’re into aesthetics and have $6000 lying around, buy a gorgeous high-polish stainless CZ-75 and save $5200. (If you actually want to shoot it the accuracy is great and it goes bang every time no matter what you feed it.)

Very true! My CZ 75 which has been customized as far as trigger pull and reset goes has never failed to go bang. I run it using nothing but action magic and wanted to see how long that product would work and if it lived up to the hype. Well to date I have put 3800 rounds through it using reloaded ammo and only cleaned the barrel after every 500-800 rounds. It has yet to have an issue. Over its lifetime it has shot at least 75k trouble free rounds. Best part is even with the trigger work I have less than $700 in it.

I’ve had 2x hi point C9s and an old style 4095 carbine. None has ever given me any trouble. I also had a $350 Rock Island .45 that ran flawlessly with any ammo I put in it.

For 6 grand I could buy 3 or 4 high quality, high capacity pistols and enough ammo to shoot for a couple of years and have some money left over for a little bit of customization. Pretty just ain’t gonna get it done.

Function trumps form, all day long.

For that amount of coin, it should run flawlessly AND do the dishes.

I think that it was Larry Vickers stated that 1911s were designed when manufacturing was done by hand and that the 1911 does not perform well when made with modern machining. His recommendation is to get a 1911 that was hand fitted.

Personally, I prefer tactical tupperware(XD45.) Eats everything, without fail. And yes, I do own 1911s–I just don’t carry them.

The GI model was not hand fitted. A production of nearly 3 million is not hand fitted. The high priced 1911s like the Wilson Combat and this work of art are hand fitted. Inexpensive 1911s built like the classic GI 45 are reliable. If you want to have a work of art spend the 6k on the Cabot. If you want a carry gun buya RIA GI model or a Springfield MILSPEC. They are built like the pistol carried by the troops in WWI, WWII, Korea and Vietnam.

The 1911’s made by Colt (et al) for WWII production were made on manual machines, ie, by hand, on fixtures & jigs developed for the purpose, just as all guns were made back then.

There often was a bit of hand-fitting on the assembly line to clean up parts to get them to work, but no more than necessary to ship the gun. They weren’t fitting for anything other than getting the gun to function reliably and ship it.

No one back then was trying (or even attempting) to out-spec everyone else with tolerances and allowances to impress armchair warriors. They were making weapons for war, and the first (and really only) criterion for this exercise was that they went “bang” and ejected a bullet out the muzzle on command.

The GI-issue 1911’s worked and worked very well with 230gr ball ammo. They worked when they were dirty. They worked when they were wet. They worked after being dropped. They worked after they were used to club someone to death. They just worked. The only people claiming that 1911’s are “unreliable” and are a “unreliable design” are young punks who don’t know jack about anything before the 1911’s that started appearing in the civilian market in the late 80’s. The 1911 passed a 6,000 round acceptance test before it was accepted as “the” sidearm for the US military 100 years ago. Everything else failed to pass the test.

This isn’t and wasn’t anything special. The 1903 Springfield “just worked,” the Garand “just worked,” the M1 Carbine “just worked,” as did the BAR, M3 Grease Gun and a host of other such weapons. The US War Department, before it was infected with Harvard graduates and MBA’s trying to conduct military campaigns by spreadsheet analysis, required reliability out of the weapons coming out of the US Army’s armory system. “Springfield Armory” used to be a real armory – not a company. They made small arms for the US War Department and US Army – and they did it well. Sidearms were contracted out to bidders responding to War Department requirements.

Back then, guns were all made on manual machines, put together by hand, with QC done by gaging and manual measurement. There was no NC or CNC machine in sight – anywhere, no CMM, no laser scanning, no Renishaw probe system, etc. It was all by hand. The Springfield Armory even used to heat treat their 1903 receivers by eye – which led to the problems with early 1903’s being damaged on bright, sunny days. After the investigation in the early 1920’s, they relented and started using pyrometers on their heat treating processes.

That’s how guns were made, and they worked and worked well. Why? Because they had some slop in them. Almost nothing in guns needs tolerances down to 0.001″. About the only guns that were ever lavishly and lovingly hand-fit from the get-go in the US gun industry were the Colt Pythons, and I’ve praised their workmanship elsewhere here at TTAG.

The 1911 was known as a reliable pistol until people started trying to turn it into a match pistol. While Colt had a “match” pistol that underwent a bit of extra fitting and trigger tuning in the mid-30’s, it wasn’t until the late 50’s that you saw the serious muckery start on 1911’s. Then people started trying all manner of mods to get the groups down to under 1.5″ at 50 yards for competitive target shooting.

This was being done because there were really no other hardball target pistols out there in centerfire loads at that time. The 1911 was “the” semi-auto pistol available in the US in quantity at that time, and there were lots of them available. They were easy to work on, and gunsmiths were starting to cater to the new military marksmanship units’ requests for more accurate pistols.

Fast-foward to the 70’s: By now, there’s a whole industry among gunsmiths that has arisen to make 1911’s very accurate for bullseye and military target work, and a parallel industry among gunsmiths to make 1911’s reliable and higher-capacity for IPSC.

Out of this era came some of the gunsmiths who now make semi-custom or custom 1911’s as an industry to themselves – Wilson, Brown, et al.

Then by the time the 90’s came around, the 1911 appeared to be on the way out. The polymer striker pistols were in their ascendancy, Glock was merely the first of many, and S&W was cranking out semi-auto pistols based on their Model 39 for law enforcement (and others) – 4xx, and then later, the 4xxx pistols.

1911’s appeared to be on their deathbed… even in IPSC, where European CZ-type pistols and double-stack .38 Super 1911’s had it all over the .45 ACP 1911.

And then, one pasty Senator from San Francisco got her granny panties into a twist about guns and rammed through the 1994 “assault weapons” “ban.” Suddenly new guns were limited to 10 rounds.

The Cheez-whiz pistols lost their hi-cap advantage over the 1911 in a hurry. Hi-cap pistols for IPSC were basically frozen in inventory.

And the 1911 came back into the marketplace with a roar. Except now, CNC shops were setting up to crank out 1911’s that didn’t “need” tuning from the get-go to get them a tad more accurate and reliable. Whereas Colt’s QC had been suffering all through the late 70’s and 80’s, the new CNC’d 1911’s were more consistent, and they’d shoot pretty well right out of the box. It was like the 1911 was reborn, out from under Colt’s shoddy practices…

Then the specmanship started. Who made the tightest, most accurate gun? Who had the fanciest CNC machinery on the line? Who could splatter the most buzzwords on their press release to impress people who don’t know jack about metal alloys, machining, gunsmithing, etc?

For those of us who know the 1911 from a ways back, it made many of us roll our eyes. In the old days, many of us who used 1911’s for target and defense had multiple 1911’s: You had a 1911 that was tuned and tightened for target work, and then you had your carry piece (where allowed) and then you had a bedside 1911. The latter two weren’t target guns, they weren’t pretty, but they sure as hell went “bang” every time you pulled the trigger.

Well, here we are. A beautifully finished, yet unreliable 1911 made to exacting specifications – by people who probably don’t understand how a 1911 really works. And that gets me to another point: Lots of people don’t really understand what is going on inside a 1911 as it functions – and it shows when they start making mods to a 1911 to attempt to achieve something. Those who do understand what is actually happening inside a 1911 can make them function easily and reliably. It isn’t obscure information, BTW. Pistolsmiths have been trading this information around for 50+ years now.

But here’s the really bitter irony in all of this:

However tight you want to make a 1911 for target work, it isn’t ever going to get you the sort of results you can buy in a pistol made specifically for target shooting, eg, the S&W Model 52. The Model 52 is so reliable at feeding, you can put an empty .38 Spl case into the middle of a magazine and you will see that pistol reliably and consistently chamber an empty case. The 52 was designed to shoot 148 gr. full wadcutters, the bullets seated flush into the case mouth, that’s why. There is no bullet sticking out of the case for a Model 52. If you tune it to eat empty cases, you’ve tuned it to eat wadcutter ammo, which is what it wants to shoot. And shoot, it does. It will shoot rings around most all target-tuned 1911’s. The AMU used 52’s for their target pistols for years and years, and they cleaned up at pistol matches. The 52 is an awesome piece of gear for a target shootist. You need only a very light load in .38 Special to get it to function, and a wadcutter makes such a nice, clean hole in your paper that you don’t even need a spotting scope to see what you’re doing. It is a pistol that is truly a joy to shoot on paper.

The 1911 was made to be a reliable pistol. If you can drop all seven rounds from a 1911 into someone’s chest at 50 yards in a couple of seconds into a 5″ group, then the 1911 has done the job for which it was designed.

It seemed to work reliably enough for Alvin York. Every time he pulled the trigger, it went “bang” and a German was sucking mud.

For the love of god someone please make that a post in and of itself. Much respect.

JWT

Pearls. All of it. Especially the part about Harvard and MBAs.

I salute you, Sir.

Wow. I think I learned more about 1911s in that one post than anywhere else I’ve read. Thank you for sharing your knowledge with us.

Most informative thing i’ve read all week. Thank you sir!

Tons of love you you, dyspeptic. Also, Alvin York’s is one hell of a tale.

I stand in awe.

I salute the knowledge You have shared with us young heathens.

I salute sir. o7

I would ad that at one point as it was deemed necessary to add manufacturers that there was concern about the interchangeability of parts since the guns could come from many sources. One of the tests was to disassemble the guns from several manufacturers and dump the parts in a basket. The guns were reassembled using whatever came out and functioned fine.

Military guns were routinely kept running with a hodgepodge of parts. I read just this week were a guy bought a pretty beat up gun when he was in the service and took his old parts to the unit armorer to exchange for new parts and kept pretty much just the frame and slide. He carried that gun for a long time. It worked.

If TTAG implemented upvoting for comments, this would most assuredly be at the top of the list for this article. I learned quite a bit reading this; thank you!

“The Springfield Armory even used to heat treat their 1903 receivers by eye – which led to the problems with early 1903’s being damaged on bright, sunny days. ”

Bright, sunny days damaged them how?

OK, without writing a long post on how heat treating works here’s the deal:

Steel has a critical temperature above which it must be heated in order to create the internal structure where you can quench (rapidly cool) the steel and make the steel hard. There is a range of temperature range for the steel above this critical temperature where you can perhaps change the outcome in the quenching, but there’s an upper limit to this temperature range, above which the steel will be damaged and irreparably so.

In plain carbon steels, you can find the lower temperature boundary of this temperature range by using a magnet; if you apply a magnet to the steel, it will drop off above the lower boundary of the required temp range; ie, the steel becomes non-magnetic. This is an old blacksmith’s trick, and it works well.

Now, what about the upper limit of the temperature range? Ah, that’s more difficult. The typical old-school technique is to judge the temperature “by eye,” ie, by the color of the steel. By the time you get into the bright red region, you’re up to 1500F… but here’s the catch, and here’s where the bright daylight comes into play: The difference in the temperature color of steel you can perceive in bright light between bright red and starting into the less red light orange range is over 200F – and being over 1700F gets you into the range where you’re going to start getting the steel too hot for the quench. In dim light, you can easily see the differences over this 200 to 250F range of temperatures, but in bright light – well, it isn’t so easy.

Once you get the steel too hot, it is damaged. Re-heating/quenching/tempering won’t cure what is wrong, you need to just chuck the steel into the scrap pile to be re-melted and go through the whole steel process again.

DG, may I recommend / request you collect your various posts into a book?

Or just write one?

I’d buy it in a heartbeat.

“In dim light, you can easily see the differences over this 200 to 250F range of temperatures, but in bright light – well, it isn’t so easy.”

Ah! Thank you… I had an image of a guy at the range on a bright day looking down at his gun…. And you were referring to a bright day at the foundry.

Please consider writing that book. Really.

I eventually will write a book. I’ve actually started writing material for said book.

I plan on publishing it electronically, for a very reasonable price. I’d much rather create 100,000 self-taught gunsmiths and frustrate the liberal agenda of gun control than make any large wad of cash off a book effort.

Towards that end, much of what I will write will concern tools, fixtures and jigs for gun work. Many people fail to appreciate just how much gunsmith tooling is specialized (and therefore, expensive). However, if people learn how to make their own tooling, they can accomplish quite a bit on a much smaller budget.

Much of what I have written so far concerns how to make cutting tools from O-1 drill rod and the use of hand files. This sounds seriously un-sexy to the AR-15 generation, but the truth is, once you learn how to make your own cutting tools and drive a file, no one can stop you, because drill rod is everywhere and you can make your own files from truck or car leaf springs. If someone wanted to ban guns and machine tools, you can still make guns.

The chapters on making your own black powder by collecting horse dung and rinsing out the nitrates to create your own saltpeter will need proofing, and that’s a project for this summer. There are other alternatives – drink a lot of red wine and collect your own urine, but they can take much more time.

I own a Government Model 1911 manufactured in 1922. At 96 years old with all original parts this 1911 never fails to function. Accuracy is amazing using standard grade military sights. It will keep up with any Gold Cup.

I carried Remington manufactured 1911’s in the U.S. Army for years both in Indochina and West Germany. Never once failed me. I do not understand people who claim to have been in the service say the 1911-A1 was inaccurate. I won an informal company level competition at Ft. Ord, California field stripping the 1911-A1 in ten seconds. I qualified “expert” with the 1911-A1.

As I age, the 1911 seems heavier than it used to. No fault of the pistol.

Cabot will sell just as many of these in a non-functioning state as they would if the gun actually worked.

Market a story, an image, a status not the actual thing for sale and folks with more money than sense will line up to buy.

And a lot will never fire it.

CZ 97b, imo. /signedczfanboy

Glorious Czechnology.

I just today rented a 97BD at the range. I shot the tightest group of 15 at five yards in my LIFETIME out of it. (I normally shoot CZ-75s). I believe the fiber optic front sight helped a LOT.

The only reason I didn’t buy the gun right then and there? *Multiple* failures to feed in a box of 50. (Also it’s the decocker style and I favor the cocked-and-locked.)

For that price I’d rather get into some full auto fun.

What is really shocking on this is the arrogance or stupidity of the manufacturer. You know this is being tested. It has already been sent back to you once because it wouldn’t run. You did some stuff to it and then sent it back again without even testing it with different ammo? What amazingly poor business practices.

It may actually be a very smart business strategy.

Most people who will spend $3000+ on a 1911 won’t be wearing it out on the ranch. Cabot Arms knows that, which means out of ten buyers maybe two will shoot it often enough to discover a problem . They could use Armscor internal parts and no one would notice-well, maybe it would be because the guns would start working right.

Further, human psychology says the higher priced an item is, the more likely a buyer will defend it regardless of the defects. If a Ford breaks a water pump, its a Detroit POS. If a Mercedes breaks a German import, $2000 water pump, “that’s just wear and tear.”

So much this. I was working for a fix it place and dealt with a ton of Dyson vacuums. Now, Dysons are just another made in china crappy plastic vacuum, but since folks had fallen for the ads hook line and sinker and paid 4 times what they are worth, they would pour in many more $$$ to fix them instead of just chucking them and buying a real vacuum. Don’t buy Dysons folks (or any other bagless vacuum really).

It may actually be a very smart business strategy.

It’s a smart business strategy if you don’t have to look at yourself in the mirror every morning. Or if you do and are a sociopath. You’re selling CRAP for more than its worth and (ab)using human psychology for getting away with it.

I love my 1911, but its not my carry gun for this reason. My Sigs and Glock are reliable but will never be as pretty as the 1911.

Get a CZ, and have both!

Or, an STI. I have an Escort for EDC which has been flawless, just like my other STIs

let’s try a new, ohio made ithaca.

i’ve only heard of this cabot jewel from the first article.

makes 1500 seem reasonable…

I’ll stick with my RIA 2011 Tactical. It had a few malfunctions in the first 25 rounds but has been flawless for three more boxes of ammo and two of those boxes were steel cased Tula.

I’ve got a ParaOrd LTC (first series they released) that’s eaten everything I fed it (1500+) only failures were shooter error.

I’ve got an FEG 9mm that ran right out of the box, has functioned flawlessly with every type of ammo I’ve fed it and cost under $300. Is it as accurate as guns costing 1,000 or more? No. But it’s accurate enough for me and I only have to take it apart to clean it, not to make it work.

I guess you can cut it, polish it, set it in 18k white gold and call it a “black diamond”–but it’s still just a glorified piece of coal. What amazes me is that it runs on that one specific–very specific–kind of ammo. I’m just non-plussed at that.

-my hypothesis: the magazine well is cut improperly at the wrong angle , and/or the frame bed is too high relative to the barrel. Either way, the next round hits the barrel and transfers momentum into it instead of feeding. The result-the slide locks early into the lugs and its game over. Its also game over for the frame, because you can’t fix a botched magazine well.A good way to test that out is to push the barrel of the malfunctioned 1911 against a solid object-if the gun immediately jumps right into battery, you’ve found out why.

This would explain the XTP feeding-because the bullet nose is just slick enough to slide past the barrel hood without pushing it forward and locking the slide early.

ST, interesting technical comments so we checked. The angle of the magazine well is 17 degrees 30 minutes from vertical which is to the original drawings as well as Kuhnhausen. The frame bed is at .373 -.005 which is to ordinance drawings as well as Kuhnhausen. Concerning “either way, the next round hits the barrel and transfers momentum into it instead of feeding,” this will happen if there is no land between the end of the feed ramp and the throat of the barrel. With respect to “the slide locks early into the lugs and its game over,” The pictures show that the slide is not locking into the lugs quite yet. The test you mention to push the barrel of the malfunctioned 1911 against a solid object-if the gun immediately jumps right into battery can also be indicative of a condition where the barrel to bushing fit is too tight.

The $6000 turd.

Yes it’s a turd.

I love it when people wave overdone 1911 “gems” in my face and then they wonder why I don’t drool. This is why. It won’t do the job. If it won’t do the job it’s not worth more than scrap price.

How do you give an overall rating of three stars to this POS? Ok, it’s a pretty POS. If it was intended to be a prop only intended for display, that would be one thing- I could buy a three star rating.

But this is supposed to be a functional firearm, right? It can’t go through two magazines without a failure with any commercial type of ammo you’ve tried? And that’s AFTER being returned to the manufacturer for the problem and using ammo they specifically recommended?

Making something that won’t do the basics pretty doesn’t warrant giving it a good rating. The looks should be a consideration only after the functionality.

Interesting review to post only a few days after the post about ‘Is Price a Factor in an EDC weapon. This article makes the point quite nicely that price isn’t related to quality when it comes to firearms.

It’s obvious the reviewer is in love with this thing for some reason.

No gun should ever be rated than its reliability rating.

Which means zero stars for this baby.

I didn’t give it an Overall rating at all. If I did it would have matched the Reliability rating. I think TTAG’s editor just averaged out my stars and put it there for the Overall category. JWT

Whoops. We’re on the same page then, and someone else dropped the ball. My apologies.

Mr. Taylor,

My apologies, and thank you for your explanation.

Agreed. A product, ANY product, that costs 6 times what high-end semi-custom versions of that same product cost, yet performs SIGNIFICANTLY worse than the cheapest budget versions (which are 5-6% the cost) of that same product deserves no stars, or negative stars. I read the first review, and was wondering wtf the reviewer was even thinking, giving them a second chance (if i spend SIX THOUSAND DOLLARS on a 1911 it better damn well work out of the box). After reading his second attempt at it, he must either be sleeping with someone who owns/runs Cabot, or own stock in their company (not serious alleging either of these are the case, this is hyperbole). I honestly can’t think of any reason at all someone would rate such an expensive piece of junk so highly.

I’d still say quality and price run in direct proportion at the lower to mid range of that curve, but beyond that it’s mostly just style and hype to fill an ego like with any other manufactured good.

I used to like Cabot and dream of maybe, one day purchasing one. No longer. I guess aerospace engineering doesn’t translate to firearms.

So very much this. I have been wondering what gun to turn to when you as a shooter reach the mechanical limits of the firearm. I naturally assumed the one with the most work put into it.

Now, I am back to having my Sig 226 St with West German frame customized by Gray’s Guns then refinished by Robards Guns with accurizing. Doing that, I still could afford to buy and customize 2 more Sig pistols the same way and get months worth the work and engraving for what doubtlessly will be comparable beauty.

And I would rather do that then disappoint myself with something that would let me down before I could even finish a single drill after costing so much it brought down my credit score to purchase.

Weeeellllllll…. actually it does. And it did so in one of the most popular guns out there today, the AR-15.

And let’s not forget, that NC and later CNC machining was created at the behest of the USAF in the 50’s.

I would rather have a Barrett 95. Or a Scar 17, Benelli M4, and HK USP 45.

Glock 41, enough said!

The Glock 21 will eat JHPs all day long, and with 13+1 capacity. Not sure how well the Rock Island Armory 1911s do with JHPs personally, but I know they do well with FMJs. The 1911 I want is a Dan Wesson Specialist in stainless. Altough I doubt it could challenge a GLOCK for reliability with JHPs.

This surprises me not in the least.

When Cabot first announced themselves to the 1911 world they were (and still are) throwing around terms like “clone technology” and “nano manufacturing”. As someone who has a machining background and actually works in nanotechnology (semiconductors), this sounded like snake oil and I publicly called them out on it. Their representative spewed so much marketing double-speak in reply that it was readily apparent to all involved in the conversation that they were just using buzzwords to generate hype.

Glad to see my BS detector was indeed functioning at full capacity.

Are you me? Very similar background/knowledge base, and I had the exact same thoughts when I first started seeing articles/posts about Cabot. Someone over there obviously knows enough about some of these things to use the right catch words and sound impressive to the average gun consumer, or even many mechanically/engineering savvy. Glad to see my feelings validated. I feel bad for anyone who bought into the BS 🙁 Caveat emptor and all that.

There’s tons of this BS in the gun industry today.

I start with the term “billet.” When I see gun companies tossing around the term “billet” – as in “machined from billet,” I know I’m dealing with poseurs and clowns from that ONE word.

Then when they start trying to impress people with metallurgical one-upmanship, I get really bored, really quickly. 4140 steel has been more than sufficient in firearms production since WWII. Want to case-harden your receiver? Then use 8620 steel. Want to use stainless? 410, 416 and 420 will work. No need for 17-4 or some such. OK, if someone were shipping a round with a MAP higher than 70K PSI, ok, I’m ready to listen to a “need” for 4340 steel in the receiver and perhaps a barrel. Until that time, 4140 will do quite well.

I’d have to say (stepping back into my former career as a EE), that much of the advertising for guns strikes me the same way as tho a computer company were offering me a PC with chips made from GaAs. Does it sound neat? Sure. It’s “neat” in the same way that an AR-15 from Turnbull that has a color cased steel receiver is neat. It’s a great proof of knowledge and skill.

Do I need it to run a browser and a spreadsheet? No.

And I’m a guy who loves highly finished guns, so I’m really irked at this result from Cabot. I could take a 1911 from any of a half-dozen companies, hand-polish, lovingly finish it and end up with a gun that looks as nice as the Cabot gun for less than the $6K price take… and it would work as well as the rack-grade gun did at the outset. They couldn’t even accomplish that here, and the reason why is that they were chasing specs.

You mention being able to do that sort of hand polishing. Who do you know that does it? Honestly, the finish alone is what I really want. But I don’t see anyone broadcasting this level of artwork for polishing as a commercial option.

I’d start here:

http://americanpistolsmithsguild.com

Oh, and that trigger is like putting nipple piercings on the Venus de Milo. Completely tasteless.

At least nipple piercings on the Venus might be kinda sexy. Those stars scream white-trash with money. Just so redneck…

JWT, I see the problem. In the 2nd photo, that’s Gloss Protective Enamel, not REM OIL. Didja pick-up the wrong can? BTW, nice holster! who makes it?

Well heck. Guess I owe them an apology. Prisoners involved with the TDCJ craft shop make all my boots, belts, and holsters. They do great work, but it takes some time.

JW –

I (and probably many others here) would be very interested in hearing about the feedback you get from Cabot…

If I was inclined to spend six grand on firearms stuff I would buy the M-14 in 308 hanging on the wall of the gun store where I do business, a Jarvis threaded barrel treated at 300 Below and an Osprey suppressor for my Walther PPQ, a Benelli M4 tactical, a Glock single stack 9 coming to us soon, a Walther CCP, a Glock 30S and some ammunition.

That sir is a MAGNIFICENT shopping list and certainly a better use of $6000.

$6000 would buy 4-5 bricks of .22lr here in central Florida…

🙂

This should have been easy to fix.

My first hunch from the evidence presented here? The extractor is too tight and isn’t allowing a case to slide up the breech face. Or the extractor has a burr on the hook, or the face of the breech needs to be polished up a bit.

Second possibility is that the roof of the chamber needs to be polished.

Fixing problems like this on a 1911 isn’t rocket surgery. That they couldn’t get the pistol to cycle reliably isn’t promising.

I would put serious money on the ejector being to too tight, because it is. And its an easy fix that I have done before on my own guns. But not a $6k gun I am trying out for someone else. Also, you can feel the slide hit something when it is going into battery, and I’d bet again on the roof of the chamber, just on where it is in the cycle.

“Fixing problems like this on a 1911 isn’t rocket surgery.”

This really makes me wonder if they had a competent gunsmith involved involved on the design / manufacture.

DG – You might want to consider sending Cabot your resume. Tech consulting can be very lucrative…

“rocket surgery.”

And Brain Science?

😉

I’m not interested in working for someone else at this time. I’ve got my shop, my deal, my standards, in an area of the US where I want to live.

I would have thought or hoped that if it were something relatively simple like extractor tension (only) that there would be at least one (semi) talented ‘smith at Cabot that was able to fix this. Yet apparently not which leads me to guess it must be either the entire design philosophy or something fundamental. I wonder if tge s-class pistols, which seem to be built differently from what I’ve read, will fare any better.

What irks me most on all this, is the inference of arrogance of the company: when addressing your complaint sending an email from someone else who does not have a problem is cold comfort. It feels like the whole correspondence with the firm has an air of arrogance, unearned, I might add.

It is a real shame as this is without doubt one of, if not the nicest 1911 I have yet seen and, had it worked I could happily have added one to my collection.

Why not call Cabot and talk it through with them? They’re nice people. Very responsive. And I’d be interested to hear the fruit of that conversation.

As a 1911 lover, this gun sounds like trash.

Would you spend $50,000 on a car where you had to roll it and pop the clutch for the first 500 miles?

My Les Baer has never had a problem and my Wilson had one issue that they fixed and it’s flawless now.

Have fun with the Cabot gun, I’m sure it’s fun but it’s clearly not reliable to be a carry gun.

You must have the unicorn Les Baer. Anyone I know with a Les Baer has had issues until a certain amount of break in. From the factory, I know a few owners who have had magazine or cycling issues. All resolved over time, but I know nobody who has one without some type of initial functional problem out of the box. No big deal, but not without issues.

BTW, I love my Les Baer but it did have initial issues.

I bought a Les Baer Premier II new back when Bomar was still around. The only problem I ever had with it was during my first visit to the range where I discovered it was shipped full of oil. I shot it anyway with predictable results, but ever since it has been extremely reliable with ammo ranging from Federal HST down to the crappiest range reloads. I’d say that it is one of my two most reliable autos, the other being a Sig 226.

I guess so. I got my Baer UTC back in 2012 and I’ve put about 700-900 rounds through it. It’s been flawless and I’ve been very happy with it.

I also had a Kimber Covert 5″ that never gave me an issue, now that I thought was a rarity.

Same thing here – Les Baer Custom Carry, worked fine out of the box and the only thing it ever choked on were 650fps Cowboy Action loads.

A thousand times this. This is the 1911 equivalent of a classic Ferrari. Beautiful, iconic, timeless design, very expensive, amazing when it works even though there’s newer, better, more reliable things out there, and a status symbol. But God help you if you need to depend on it. The classic 250 GTB ate driveshafts regularly because of a bad design from the factory, and that’s when everything was working fine. Maintenance and running

Sorry, it posted before I was done – maintenance, running and repair costs annually will exceed the value of something you should depend upon, likely multiples of the same.

6000dollars? Once again wrong…

I have a Les Baer Premier. Yeah, I had an awful time for the first 500 to 1000 rounds. So much so that I wanted to sell it. I kept with it, and sometime after 1000 rounds (I can’t remember exactly when) it just started to work. No more issues, I do not have to lube it every 50 rounds it simply works. I clean it after each range trip and feed it whatever gun food I find and it works without issue.

But boy, did I have a miserable time with it at first.

It is one ugly gun compared to Cabot and some others, but it runs great and that is all I care about.

What? Are you sh***ing me? “There are lots of great guns that won’t run well out of the box, they take 500 rounds or so….” If consumers are stupid enough to accept this level of incompetent design / production, they’re allowing manufacturers to bend them over and “break” them in (the consumers)….without the benefit of lubricant. Have you ever seen ANY Ruger or Glock or Springfield that needed 500-7000 rounds to break in? Me either. Why do shooters even permit this incompetence to continue? There is NO SUCH THING as a “great” gun that requires any breaking in AT ALL! The only acceptable level of performance is 100% reliability right out of the box.

If a manufacturer can’t give you this, spend your money elsewhere and support companies that get it right the first time.

There are huge segments of the gun community who think this is perfectly normal; it doesn’t seem to occur to them that others regard it as a sign of POS.

Someone on another forum bought a Rock Island 1911 and proudly took his new toy out and reported a handful of various different malfs on the first day. He then concluded his post with “no issues.”

When I challenged him on that blind spot, he said this was totally normal during break in. I didn’t even try to argue back.

I agree totslly. If a gun requires breaking in then it is not ready to sell yet. Manufacturers shoukd be doing it themselves if they say it needs doing or it isn’t fit for sale in my opinion.

I don’t mind extra care or more oil etc… but if a gun doesn’t go bang, it’s not a gun that works. Simples.

This Cabot is making my Sig Scorpion teething problems look positively minor. Why is it that 1911 problems are either fixable by a competent ‘smith that knows the platform and the variations, or such a clusterf**k that even the shop that built them can’t fix it? Have the specs deviated that much, or is it too many ignorant bubbas thinking they can build a reliable homage to Mr. Browning?

The problems in ultra-tight 1911’s are the same sort of problems you see in benchrest rifles.

BR rifles are exquisitely machined rifles. Benchrest shooting, in general, is a competition between gunsmiths first, shooters second.

But now take a BR rifle off the bench and out into the field. Heck, don’t even get that far. Just get off the bench and get down on your guts in the dirt to go prone in a high power competition. Whoops… the bolt won’t close. Or worse, it won’t open. Why? Because it has gotten some dirt into the action, and the clearances are so tight that this is now a real issue. It is common to see BR rifles set with headspaces to minimums, chamber necks to be under-sized. The brass needs to be lovingly hand-prepped on every single round. Primer pockets are made uniform, primer flash holes are drilled to a uniform size. Case necks are turned to be concentric. Bullets are seated with tender loving care. Powder is measured down to the grain. Firing pin holes in bolts are bushed, and the new firing pin hole in the bushing is set to minimal clearance for the pin to come out of the bolt face.

On and on and on and on and on and on and on and on and on and on and on goes the quest for perfect uniformity, perfect fits without any slop, bank-vault lockups, perfectly repeatable firing pin strikes, you name it.

And when a wee little bit of gunk gets in the way of all this precision… oh well. So much for that string.

Does that mean that the Mauser turnbolt design of 100+ years ago is faulty? Hardly. Have the specs changed from the 1890’s? Nah. People have just tried to optimize everything down to a level where even very small aberrations of dirt and fouling matter quite a lot to functioning.

SOMEONE HIRE THIS MAN. I would pay to listen to this.

I found your link but the reply for that thread is done. Thank you for that, I’ll look into contacting the pistolsmith group and seeing what they can do when I’ve finally got a piece worth polishing.

firstly, kudos to TTAG for posting a second, completely honest review.

secondly, why would someone buy this as a weapon they even intended to fire? For 6000, I could buy a combat rifle, 7 magazines, an aimpoint, a sling, a grip, a light, a side arm, mags for that, ammo for that, a plate carrier, pouches, a first aid kit, plates, boots, and a bdu.

I’m sorry, that’s not true. I could buy TWO sets of all that.

If you’re going to spend 6000 on art, get something that is going to *increase* in value over the years.

Out of my 1911’s, my Les Baer has been the most reliable (out of the box to current – and I don’t subscribe to the “run your 1911 wet” idea).

After running it in Single Stack Division, over 25k rounds, I’ve never had a malfunction outside of worn magazine lips & follower, or improperly sized ammo (reloading mistakes on my end).

For 6K, I would EXPECT (read: DEMAND) perfection beyond my current ownership of several 1911s. And that current standard is my LB.

My $400(well, $389) Charles Daly/Armscor ran flawlessly out of the box for 10s of thousands of rounds. The Kimber I traded it for went 60000-70000 nearly perfect rounds before it got stolen. The Kimber was $650. The only problems I ever had were ammo related.

For $6k, Cabot should be ashamed.

My first Sig RCS ran very much as this gun is described to have run. I sent it back 3 times and on the third time they replaced it. This one runs like a 1911 should. It fed the first round and has fed every other round since regardless of brand and I’m now approaching 1000 rounds. It has been wiped down but not really cleaned. It cost me less than 900 bucks and is very accurate.

Do you consider cost when choosing an edc?

I’ll take an STI Trojan and an STI Escort for $2500 and use the left over $3500 to buy components to reload 21,000 rounds of .45.

Quick question first – you weren’t thumb-dragging above the safety, were you? Just a thought based on the FTF photo – no offense meant!

In a word, I’m incredibly disappointed. I was SO hoping the Cabot just had a few teething issues, but this thing sounds like a boat anchor. NOT saying any teething issues would be acceptable in a 1911, or any other firearm for that matter – if it’s supposed to go “bang”, it should go “bang” – that’s the designed purpose of the thing, after all, right?

My EDC is an SR1911 – yes, the cast wonder from Arizona. I bought it sight-unseen, unfondled, NIB, for less than 700 bucks. I expected it to function flawlessly from round 1, and it has (current RC is just over 4k) with nothing more than a total teardown to clean & lube it with froglube paste the night I brought it home. It’s never had more than a basic field-strip & clean every couple of hundred rounds (when I can’t stand the grunge around the muzzle anymore – because “stainless”, you know) I haven’t stoned anything, tweaked anything, twerked anything (okay, okay – I did buy some black diamondwood grips from Ruger for it) since I bought it, and it’s dead-on reliable – I DO trust my life to it.

I think Cabot just got wrapped up in their own PR – such a shame, because it really is a gorgeous turd! 😉

Thanks for that feedback. I’m thinking of changing my CCW piece from a G36 to a SR1911 Commander. I’ve had a scare recently with the G36, and I’m going to quit using a Glock for my carry piece.

I think you’ll like it, DG. I wasn’t blowing sunshine up anyone’s skirt when I said no failures! I will admit that I’m a long-time 1911 guy – have been since Uncle Sammy gave me one to carry in my tank “way back when”. Is it a tack driver? Not a chance. Will it put an entire magazine on a pie plate out to about 25 yards, when you do your part? Oh yeah!

I’ve literally shot every type of .45ACP ammunition I’ve been able to find through it over the years – the point of impact changes a bit, as you’d expect, but they ALL fed, all went “bang”, all extracted, and all fed the next round. I will admit to buying one additional magazine as well, a Chip McCormick, but that was because I really don’t like the non-removable big plastic bumper on the end of the factory Ruger 8rnder – the CM has the same capacity, and sits flush with the bumper removed. You can’t take the bumper off the Ruger mag (heh – I SO wanted to say clip just now), an even if you could (by say installing a floor plate from another manufacturer) the thing still projects past the bottom of the grip.

My EDC/Defense load is Federal Premium Personal Defense 45 AUTO 230 grain Hydra-Shok JHP. My practice load is “any 230gr ammo I can scrounge” but usually Winchester white-box – the PoI change is minimal (I don’t shoot for head-shots – I shoot center-of-mass – so the difference between training round and carry round is…gut shot vs heart shot. I’ve also shot a LOT of 185gr (beggers/choosers) and about the same amount of 200gr. I carry condition 1, because that’s the way I was trained, and that’s what I’m familiar with.

I DID make an attempt to go the fantastic plastic route. I even changed calibers! I got an LC9 for a birthday present – neat little gun, also goes bang, but it experienced a hanging firing pin issue (excessive dry firing, mea culpa, mea culpa – I broke the little pin that drops through the firing pin to keep it aligned, and it got stuck in the “fired position”, keeping the gun from chambering the next round) and since it demonstrated a mechanical failure, it’s now a range toy. I didn’t ship it back to Ruger to fix it – I got on their site, ordered what broke, and replaced it – I like the thing, I just won’t trust my life to it!

I would be interested in hearing about your experiences with the SR1911 Commander – I’ve been toying with getting one of those myself.

I have shot 1ks of rounds out of just about every pistol Wilson Combat makes. I have also done the same with just about every high end 1911 on the market – Brown, Baer, Colts, S&W, Para, Sig, etc. and the CZ 97 (the wife is Slovakian and shoots nothing but the CZ 75B – great pistol). In my view Wilson makes the finest 1911 period! I like my pistol to be “tuned” to my preferences in terms of trigger (pull #s, sear roll-out, etc), sights, etc. Depending on the gunsmith Wilson might hit all my preferences out of the box. But if they don’t I call the gunsmith discuss what I want, send the pistol in and no more than 2 weeks later the pistol’s back and right on the mark, no charge. And they offer a pistol for just about anyone’s functional tastes. My ammo is Speer Gold Dot 230gr. JHP out of a 5″ and Barnes 185gr. out of a 4″ and a Wilson will chew through 1,000s of those rounds without a hiccup with dead on accuracy. Just read the Wilson website and the Cabot site and you get the message real quick. Wilson is by shooters and for shooters and Cabot is full of BS for idiots.

There will always be a niche market for those who feel the need buying an item they don’t want and can’t afford to impress people they don’t like. Cabot appears tailored for that small market segment.

I own a WWI Government Issue 1911 (sans A-1). This 1911 is 100 years old with all original parts. It is also equally, if not more, accurate than my Series 70 Gold Cup.

Unlike the Cabot, my 1911 has a lanyard attachment at the base of the grip providing me added security should I ever have to “go over the top!”

Brian Zins, 10 time winner of the NRA Pistol Championship only shoots Cabots! I’ve never had a feeding issue with any Cabot after thousands of rounds. The only people posting have never fired a Cabot and sound like they dislike it because of its price. Comment AFTER you have fired the gun.

I understand that this is a presicion firearm. What I don’t understand is that it’s a precision firearm that won’t shoot all brands of ammo. Am I to understand that this will only be used as a competition gun? I would much rather spend my money on something that works reliably with all kinds of ammo. Especially if I’m spending 5000 bucks on it!

If you love to wear hoodies? so get this amazing Feel The Beat Hoodie Moreover, it has a hoodie-style collar with a pullover front closure and rib knitted cuffs to hold your wrist. All these amazing features make it one perfect casual outerwear to get compliments from your fashion friends. Discover now the best deals and amazing prices.