The first gun I ever built was a single-shot shotgun made out of scrap I found around the ranch. I was probably ten years old. It was awesome.

I didn’t make another gun for a few decades. Then it was a flintlock. It took me about 200 hours. Since then, I’ve built all sorts of guns, and all for the same reasons.

It’s fun. I learn a lot.

So it was with joy that I embraced the opportunity to review a few different products from 80% Arms.

The first was their GST-9 Build Kit, which, along with their GST-9 Jig and a magazine, allows you to completely finish your own GLOCK(esque) striker fired double stack 9x19mm polymer framed pistol. If you’ve read about the problems other 80% makers have experienced recently, the 80% Arms build kit is different in that the jig and slide rails are sold separately. You have to buy at least two separate items to build and complete the gun.

The GST-9 Pistol Build Kit includes the GST-9 modular frame, grip extension, a Wraith RMR-cut complete slide, a match grade G19 fluted barrel and a G19 lower parts kit.

Despite the guns and other things I’ve built, I am functionally mentally retarded when it comes to making anything. Really, I’m a confounded electrician, a lousy machinist, and if the Lord had commissioned me to build the Ark, the porpoise would be the most intelligent life on the planet.

And yet, the total time to complete this build, from the moment I opened the box to the time a good pistol was completed and ready to shoot, was one hour and 55 minutes. I read all of the directions before I started, and then read and re-read them as I went through.

It was so simple that when it was finished, I function checked the gun, turned to a buddy, and said, “Holy crap, I can’t believe that worked.” Nothing is ever that simple for me. This was.

In order to save time and get the job done right, I used my buddy’s home shop, since he has all sorts of fancy tools. It turned out that I needed none of those fancy tools at all, and using his shop burned time since I didn’t know where the basic tools were located.

If you knew where all the tools were and had a solid plan before you got started, there is no reason at all that you couldn’t do a great job getting the lower receiver completed (the actual legal firearm) in less than 30 minutes. It took longer to assemble the small parts and the trigger into the frame than it did making the actual frame itself.

The tools I used included:

Drill bits and cutting bit (included with the kit)

Drill press

Dremel tool

Clamps

Wire snips

X-Acto knife

Compressed air

Metal ruler

File

1200 grit sand paper

Punch

Mallet

That’s it.

The instructions are short and very simple. They are so brief that, before I read them, I wondered if these were the whole thing and if I was expected to go online for the full instructions.

Those are the full instructions. It’s one page, front and back. Everything is color coded, and it’s just a few simple steps. When it comes to the basic process, you’d have to work hard to screw it up.

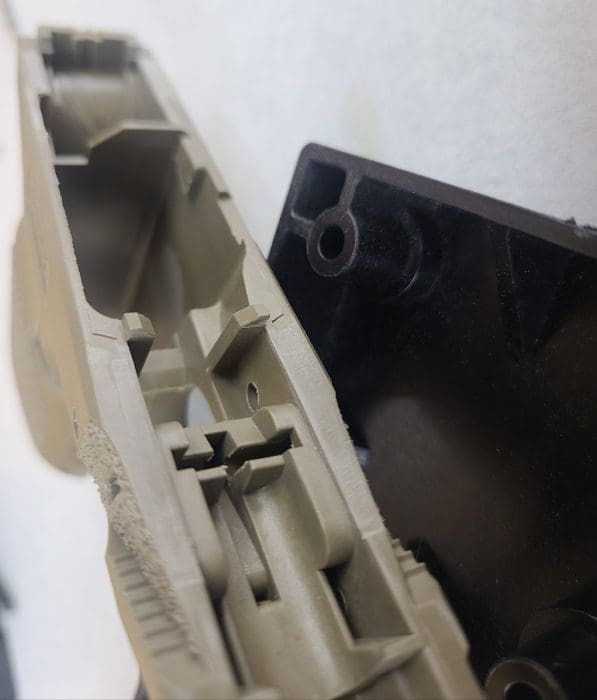

The only way you could really mess this up is by going too fast and not paying any attention. This starts with the four tabs on top that stick out from the frame.

You could remove these with a rotary tool, but really, flat faced wire snips are ideal and give you a flat cut right up against the frame. I followed this up with a wee bit of shaving with an X-Acto knife, which turned out to be completely unnecessary.

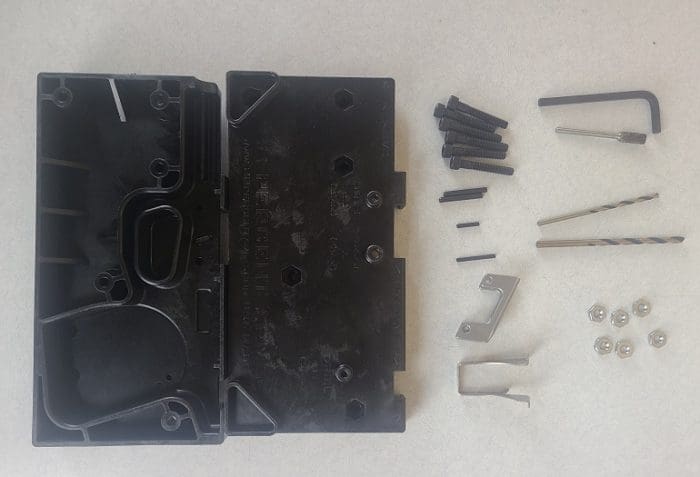

Next, the frame goes into the jig.

Again, the jig itself is sold separately. I had originally assumed that the jig was a one-time purchase deal, but this is not the case. The jig set must be purchased with each frame (price: $29.99). The 80% frame can not be completed on its own, as the slide rails come with the jig, not with the frame build kit. So you have to purchase both independent products every single time.

Put the frame, minus the rail sections you already cut off, into the jig and lock it down with all of the nuts and screws provided with the jig. Make sure the jig closes completely, but hand tightening with the short end of the supplied Allen wrench is all that’s necessary. The directions are crystal clear here. Just follow them.

Now it’s time to drill six holes.

I used a drill press, and something like that is helpful. It’s possible to do this with a hand drill, but you’ll need one with a bubble level and a steady hand. If you’re going to go the hand drill route, build yourself a simple frame to hold the drill in place and restrict is movement.

The ideal tool for this job would have been the Dremel Rotary Tool Workstation and a Dremel tool. The polymer isn’t hard to cut at all, and the drill isn’t doing much work. The simple Dremel $50 workstation/press would have done the job just fine.

No matter what you use to drill the holes, you’ll need to make sure you lock the jig down nice and tight so that it doesn’t move at all when you’re drilling. This is the part that matters most. Take whatever time it takes to get this right. There’s no going back to put polymer back on the frame if you screw up.

I set the jig on the plate of the drill press and measured how far the press went down so that I could make sure that I didn’t drill too far through each side. You want to drill through one side, but not through to the other. The instructions are, once again, very clear here.

The instructions say the jig is intended to be in a vise during use. Many folks have a drill press. Fewer have a drill press with a vise set-up on the press platform. A vise isn’t necessary, but clamps are.

Keeping the press turned off, I lowered the ram with the centered bit inside the chuck until the bit was into the pilot hole column on the jig. I then locked the depth of the cut and clamped the jig in place, all while the bit was in the pilot hole column. This ensures that the jig will be exactly where I want it when the bit is raised, turned on, and lowered again.

The polymer cuts very quickly. There’s almost no resistance at all when using the supplied bits.

Carefully repositioning the jig for each hole on each side takes a bit of time, but it’s worth it. In short order, I had all of the holes perfectly drilled. I blew it out with compressed air and moved on.

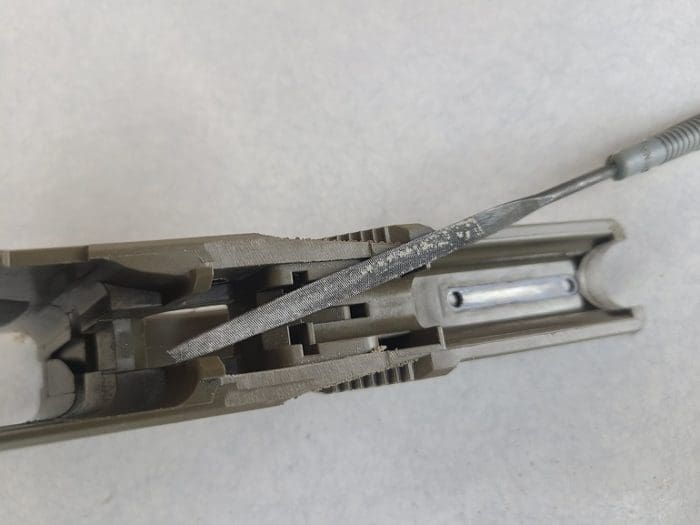

Last is removing the material from the front of the frame (front cross blocking member) to be able to accept the slide. This is best done with the supplied cutting bit and a rotary tool, but there’s no reason you couldn’t do this with nothing more than an X-Acto knife and sandpaper.

Finally, I moved on to sanding this channel as well as where I removed the tabs from the top of the frame. For this, I simply started with a file, working the top with the flat and the front channel with the round. It took no time at all, and I finished by wet sanding with 1200 grit paper. Whenever possible, if you are sanding, use a guide like a dowel for round sections and a block for flat sections.

I took the rail sections from the jig kit and tested their fit. Perfect. We’ve got a firearm.

If you did everything right — and it’s hard not to — there’s really no need to put the rail section in at that time, as you’ll need to pull them back out to install the trigger. But still, it was nice to know it all fit together well before starting the rest of the build.

At this point, you’ll need to remove the trigger pack from the packaging. They look like stock OEM GLOCK Gen 3 parts to me. I pieced together the trigger, magazine release, slide stop, and then put the rails back on.

80% Arms’ frame build kit includes a modular grip. If you want a shorter, GLOCK 19-sized grip, pin in the shorter grip module. If you want a longer G17-size grip, pin in the longer module. They are completely interchangeable and you can go back and forth if you want.

Blow it all out with some compressed air, lube it up (this one got a liberal spray of the Rem Oil I had on-hand) and slip the included complete slide onto the rails.

Voila! You now have a complete double stack semi-automatic 9x19mm pistol.

So, how does it shoot?

Pretty much like a GLOCK 19. Go figure.

I was close to the Range at Austin when I finished the gun, so I headed right over there. I didn’t have a GLOCK 19 magazine with me, but I did have a couple of magazines for a GLOCK 17 and one 33-round GLOCK brand magazine, and 200 rounds of range ammo.

At the Range at Austin I ran into someone shooting a GLOCK 19 — zero surprised there — and she allowed me to borrow one of her stock mags.

I loaded up a G17 magazine and pulled the trigger. Nothing happened. I racked a live round out of the magazine, noted a light primer strike, and did it again, with the same result. I had just sprayed the completed slide down with Rem Oil and mounted it to the frame 20 minutes before so I tried one more time.

BANG! Yay.

From that point on, for the next 200 rounds, not a single malfunction of any kind occurred with any of the three kinds of FMJ ammunition I tried, as long as I was using the G17 or G19 magazines.

But not a single round would even load on its own in the 33-round magazine. Every single one had a first round failure to feed, which required a tap to the back of the magazine to chamber it. Again, all of the other magazines worked flawlessly, so maybe this was a bad magazine.

Upon getting home, I loaded the same 33-round magazine with the same ammunition into a stock GLOCK 19 and tried it out. It loaded just fine. I swapped the frames, using the 80% Arms slide on the GLOCK frame, and the 33-round magazine loaded fine. Something is up with the homemade frame and the 33-round magazine.

What is particularly interesting is that I put another 100 rounds through the complete 80%, this time using Magpul G19 magazines and assorted hollow point ammunition, again, without a single malfunction. I then shot another 100 rounds of my own reloaded 147gr flat-nosed rounds through both the G19 and G17 sized magazines, manufactured by both GLOCK and Magpul.

Finally, after I thought the review was over, I had a friend offer who let me us his 32-round ProMag magazine. The gun had zero malfunctions of any kind with this particular extended magazine. If I didn’t have a GLOCK 33-round magazine, I wouldn’t have found any malfunctions at all in 432 rounds.

At no point after the initial assembly did I re-lube or clean the pistol in any way.

When it comes to precision, the homemade pistol shot just as well as the GLOCK brand GLOCK G19s. Which is to say, OK.

Shooting off bags at 25 yards, Armscor’s 115gr FMJ shot an average of 2.2″ five-round groups, averaged over four shot strings. I didn’t have all of the different types of ammunition I like to have on hand for a review this time, but I don’t think I need them.

This particular gun likes the Winchester Defender 147gr HP round, printing 1.8″ 25-yard groups on average. That’s a great, very capable defense round, and I don’t think I’d look any further for what to carry in this particular pistola.

In shooting the gun I built from the 80% Arms kit, I noted a few real differences between it and the stock GLOCK frame. First, the modular grip is a tad bit larger in diameter. It’s well textured on every side, and seems to follow a very similar grip angle as the stock GLOCK. The above photo shows the GST-9 laid on top of a stock Gen 4 GLOCK 19.

You’ll also note that gone is the GLOCK brand GLOCK rail, replaced on the GST-9 with a standard Picatinny rail.

What I really liked was the small angled thumb rest cuts near the front of the frame. They fit my thumb perfectly, and not only provided a great tactile reminder of where my thumb should be, but also allows me to keep steady pressure there in order to reduce muzzle rise during fast strings of fire. It’s also a good position for your trigger finger to rest on when not yet ready to shoot.

If you choose to order the slide as well, it’s a bit of an upgrade from the stock Gen 3 GLOCK models. It’s got fancy cuts and a fluted barrel. The real benefit is that it comes pre-cut for an optic.

As a huge benefit, I was able to verify that this pistol fits a wide assortment of Kydex and leather holsters originally made for the G19.

If you’re looking for an inexpensive complete polymer striker fired pistol, this is not the way to go. The 80% build kit is $750, as much or more expensive than most new striker fired polymer pistols of this size. You’ll also need to purchase the jig kit separately in order to complete the build. Again, that’s another $30.

If you are looking for a polymer striker fired pistol to build now, this is not the way to go. The current backorder on the complete kit is about nine months, although 80% Arms says they are rapidly increasing production and plan to be current by the end of the first quarter of 2021.

The real reason to purchase something like an 80% build is that it’s fun, and you’ll learn a lot about how the firearm works and is put together. For me, that’s well worth the price of admission.

The 80% Arms GST-9 Build Kit and GST-9 Jig Kit were great. They let me build a very well functioning firearm, with more bells and whistles than most polymer-framed striker-fired pistols, in less than two hours with simple tools.

If I built another one of these, I’d do it with nothing other than manual hand tools, just for fun, and to see it done so easily. I didn’t expect to be so satisfied with the finished product, but I sure am. It turned out to be a fun build, and a fine little gun.

Specifications: 80% Arms GST-9 Build Kit

The GST-9 Modular Frame

GST-9 Grip Extension

The Wraith RMR Cut Slide – Completed

Black, Straight-Fluted, Match-Grade G19 Barrel

G19 Lower Parts Kit

Price: $749.99

80% Arms GST-9 Jig w/Tool Kit and Slide Rails

Must be purchased separately to complete any GST-9 lower receiver.

Price: $29.99

Rating (out of five stars):

Overall * * * * *

Simple and fun, the kit and jig end up allowing the user to produce a very capable firearm.

I wish I could post the “Somebody come look at this.” ATF meme.

Somewhere an aide to my governor cried out and was quickly swarmed by enough lawyers to figure out our tax code who will spend the rest of the holiday finding ways to make these blocks of metal and plastic illegal(er) somehow. Wouldn’t be my first pick of pistol setups but the interchangeable grips are a nice feature on a glock if they prove sturdy enough to hold up.

80 percent arms has just increased the price on the GST- 9 to 149.00 and the 80% full build kit went up about 100.00. Seeing how the Country was betrayed yesterday, anything to do with firearms is going to go way up.

Wouldn’t matter IF one could have the item(s) delivered. I have been waiting nearly a YEAR and not a peep as to when I “might” receive my order Their lack of TRANSPARENNCY and COMMUNICATION leaves one to wonder if this is real or a SCAM!!!

Wow that’s pretty cool. Stimulus stimulus where art thou.

Wish they did something MONTHS ago about availability, I inquired 3 months ago about availability yesterday finally got an answer they are working on the orders from APRIL, you’ve got to be kidding! With COMMIE Joe and Commie Kamala going after just such a pieces of Plastic, really, terrible timing guys.

One month from now these will be declarer illegal through executive order and the ATF will shut them down. No thanks for a visit from the ATF! Remember the other 80% company was raided and they gathered all of their wonderful data (aka NAMES and ADDRESSES!). NOW, they have begun collecting them!

V-I-S-E.

A prostitute is a vice. Drugs are a vice. Gambling is a vice. A thing that clamps stuff so you can work on it is a vise.

Not the same.

Helpful article, b.t.w., just the thing that actually is a gun article and that TTAG rarely publishes anymore.

You say “vice” like it’s a bad thing.

“You say “vice” like it’s a bad thing.”

Kinda adds new meaning to the term “Vice Grip”, doesn’t it?

*snicker*… 😉

Kinda free with your advise…..

I have several Poly Glock Builds being a Glock nerd and all..(nerd is different than fanboi )

Gotta say I like that thumb rest. Resembles the ‘GoGun gas pedal’, but at $750? Will pass on it…maybe one day if our Rights are ever secured. Right now our entire country, culture, government ect It’s all madness! I don’t know where it ends other than separation.

On the 7th day of Christmas the government gave to me, $600 to purchase a P80 kit, on the 8th day of Christmas the atf decides, That a p80 kit is illegal, I like working on and building gun’s to been doing it for year’s, it’s been legal to do so since the 1600s now the atf and the government is wanting to change that in other words they wanting to rewrite our constitution which is supposed to be upheld and protected by the government, now what does that tell us?, I see like this a government official that is elected by the people that goes against the Constitution of the United States is committing treason, a traitor, it’s just that simple, that’s a crime that seems to me they getting away with, nothing done, if this is allowed we will become a communist nation, now on a better note, I wish each of you a very blessed and Merry Christmas. 🎅🎄

Is JW looking for martyrdom? In this day and age one probably should not be advertising that they have an unserialized firearm on the internet.

Still a nice looking pistol. Looks better than most OEM products.

Stand for something or you will fall for anything.

Martyrs gets songs and statues. Those who plan for long term resistance win the war.

You’re disgusting.

I just spent over two hours on PX with possum. He’s an entertaining gentleman. Saved him my contacts. Invited him down from Kansas anytime. I think I may have made a new friend. Isn’t this what’s this is really about?

what’s px? i only know post exchange…

tsbhoa, you are correct. PX does stand for post exchange. In LE PX was slang for a phone call.

You are a loudmouth phony beating your chest and telling everyone how tough you are.

Read up on resistance movements. Do you think they walk around with resistance stamped on their forehead? They do rheir best to remain unnoticed because dead or imprisoned resistance fighters are no use to anybody, kind of like you.

For a guy who went to Afghanistan you sure didn’t learn much about this sort of thing.

I could not be more clear. You are a coward and you are disgusting. You disgust me. I feel dirty even having spoken to you.

At 0937 on September 11, 2001 I was in the New Foresman Conference Room in the Pentagon.

At 0700 on September 12, 2001 I was back at my desk in room 3D200 in the Pentagon. The building was on fire about 3 corridors away.

Enough said about that.

You are fool who thinks beating your chest makes you look brave. It just makes you look stupid. I am sure there more than a few Taliban who laughed at you because you thought they were on your side.

And the whole time you cowered under the protection of better men.

Coward. Traitor. Sub human filth.

tdiinva, everyone knows you’re a troll so your comments are worth about as much as tadpole shit on the bottom of a stagnant pond. Still, be careful what you say to JWT. I made the mistake of mis-speaking to him once. He can blister your ass. Then again, your ass is probably used to worse.

I agree, the only thing that allows evil to triumph is good men who stand by and do nothing…. and when evil plots to destroy good men, their only defense is peaceful men well trained in the art of violence

It’s perfectly legal. It’s been perfectly legal to build your own firearms since before the country was founded.

This gun wasn’t built from a complete kit. 80% Arms doesn’t sell a complete kit like Polymer80 does (did).

Well, that most likely explains why you have to purchase the slide separately.

Even IF (big if) ATF reverses themselves and calls it a gun, 80% Arms would be liable for selling an unserialized gun, tax avoidance, and not shipping through an FFL. Hopefully, 80% Arms submitted their partial frame and got approval that it wasn’t a gun. JWT still would have broken no laws, but ATF might show up at his door and ask for the contraband.

Tell them to send bachelors. #omwtfyb(atfe)

You will meekly give them what they want. How do I know this? Because you like to tell everyone how brave you are. Chest beatersxare talkers, not doers.

Pure projection. Filth.

Pardon me, but I don’t understand your attack, tdiinva. I don’t see how anything John does, writes or advocates affects you in the slightest so why get bent out of shape? What possible good can come from flaming someone you’ll likely never meet from an anonymous posting on this or any forum? At least John uses his own name and most people around Iowa can figure out who I am, although I’ve been toying with changing over and just using my whole name insted since I make no apologies for my way of life, my beliefs, what I’ve done for a living over the past 68 years and what I hold dear and uncompromising in the final analysis.

I’ve posted this “saying” on TTAG and elsewhere that while the Second Amendment needs to be defended right now, it also needs to be celebrated- daily, by any and all who are willing to participate. We need to leave this “hide my guns/don’t let anyone know I stand for the Constition mentality behind and be proud to be an American again, guns and all. If you do not stand up for your rights and liberties when it appears you are surrounded, you’ve let the progressive bedwetters win.

From your postings it sounds like you have enough to worry about. Make sure you bury your guns real deep. I’m going to keep shooting mine, 80%ers and all.

Are you a small town near LeMars? I’d buy you a beer if you were closer to Des Moines.

It is way too easy to figure out who I am.

Until the 1968 GCA, many firearms were unserialized, and still trade hands thru FFL’s who can’t record a number. None were ever assigned. Serial numbers became a thing after that, for ATF licensed makers, not the general public.

KNOWING the law is important – too many don’t.

If I have any real objection over 80% kits – and the 80% is just a concept, not an actual ATF calculated number – it’s the pricing. For the most part they are more expensive than the actual finished product, whether handgun or AR lower receiver. Even tho the paperwork to keep them legal is part of the overhead costs, as is their controlled thruput on the fabrication line to prevent any question of them being mishandled. Ask Stag Arms about that.

Trying to make it more than that, or speculating about future issues the ATF may or may not bring up is really part of their conduct under their Agency requirements as outlined by Congress and interpreted by the Courts. The ATF has lost more than a few cases at that level, and the most interesting to have arisen lately is the definition of “receiver,” which former ATF experts have testified in court does not apply to 60% of what is being sold. Hence why the ATF actually pussyfoots around when it comes to major actions. They look for individuals to personally bankrupt with extenuating circumstances that appear criminal in the public eye. Trying them in the court of public embarrassment is how they operate.

Worry about that more. Congress at present won’t give a lick about protecting your rights when they are avidly trying to remove them from you.

And no, a lower kit for $700+, no slide no jig? This is why I recently avoided kit guns or building my own. For that money I could buy two medium frame polymer 9mm’s with 18 shot magazines and call it good. Finished, ready to go. Being a local dealer had two but I needed only one, we arrived at a sale price. I left in 20 minutes including NICS and had a brand new working firearm for half the kit price.

Kits and building a firearm with the exact parts you want is fun, but does tend to be a snapshot of what is currently in fashion. At a cost of six of one or a dozen of the other, it’s up to you. I’ve built two AR’s and so far, I could have saved money if I just had enough of it at one time. If it’s about cash flow or an abundance of it is what makes the difference.

I have a 33 round OEM Glock mag that I have had for 12 years or so. When I first got it, it was finicky with ammo. WWB was the only thing would feed reliably from it. After years of use it seems to have loosened up. A few years ago it started feeding everything reliably. So it could be the mag. It may just need breaking in.

Glock OEM 33 round mags often have issues in a Glock 26. Maybe extra weight at bottom and shorter grip lets the feed lips move too far to the rear and point too far up. With these modular grips, the mag well might still act like a short one.

CDN was selling the made in Korea 33 round Glock mags at one time, I can attest that they work well.

That sounds like a fun project, but it does seem a little pricey for something you have to finish yourself. Still, in today’s market, maybe not.

You get a legal lack of a serial number included with the higher price.

I’m not a prohibited person, but the way things have been going, having a few of these around may be a prudent idea…

Glad I ordered mine before it got more press.

JWT, if you, or anybody else at TTAG ever does a shop project like this again, could you please consider documenting it with a video? I realize it’s a relatively simple procedure, and your directions provide a lot of clarity, but a video would certainly fill in even more blanks.

YouTube currently has a vendetta against gun build videos…

Not interested.

That’s fair. It’s not like the web desperately needs another gun video. And by the way, thank you for your service.

JWT,

I appreciate that your recovery time is allowing you the opportunity to catch up on all sorts of firearm-related reviews…the more, the merrier.

Good article! Your photos are clear and relevant…and your usual slightly twisted humor is evident.

However…

I suggest you engrave the following S/N: KMA-2020 and ship the (now) properly identified weapon to my neighbor (an FFL holder) wherein he will transfer this highly suspect “kit gun” to me for safekeeping (please surrender all appropriate ammunition and magazines at the same time in care of the same shipping address). Note that this is NOT a seizure…only a common sense “suggestion”…

(do I need to add *sarc* for the preceding paragraph?)

On a more serious note: almost $800 for a Glock Gen3 clone (with the original Glock grip angle *ugh*) is a bit more than the “toy fund” has in it right now. I don’t believe you mentioned which sights you installed…there’s another $100 or more for decent night sights (or $20 for factory original plastic wonders).

I do like the aesthetics of the slide!

I’ve got a Polymer 80 build in progress with a tiny problem, and Polymer 80 seems to be aware of it, based on the video they have referring to it.

The issue is the alignment of the metal rear rail piece. I was extra cautious during frame drilling, using a drill press for each side of the frame, so the hole is correct. The assembly video mentions the hole in the metal piece may not be correct, and if there is a mis-alignment, to modify the the metal piece.

I’m paranoid doing that may result in mis-aligned frame rails. Has anyone who had built a Polymer 80 frame come across this issue?

I haven’t gotten a slide assembly yet, so I’m pausing the build until I get one to verify things will align when assembled.

Any recommendations on a G-17 Gen-3 slide assembly that won’t break the bank with goofy fancy cuts in it? Just a solid, serviceable slide will do nicely…

@Geoff,

I used a couple of Brownell’s slides for my Poly80 builds. They are available with or without “goofy fancy cuts” (both of mine do not have the cut-outs). No issues with either of them (a G17 length and a G19 length). Currently they are about $210 each. Every once in a while they go on sale or there is a coupon code and / or free shipping.

Thanks, looks good… 🙂

I had issues with the rear rail when initially putting it in. I had to do a little metal filing to get it to seat fully so as to get the rear pin through it.

Does the pin go into the frame fine without the rear rail? Does the pin go into the rear rail just fine by itself? Tough to expertly diagnose the issue without seeing it.

Best I can say is check out ‘MarineGunBuilder’ on YouTube and watch his videos on rear rail fixes. Between his videos and my own diagnosis of the issue, I was eventually able to get the rear rail to seat & the pin in.

“Does the pin go into the frame fine without the rear rail?”

Yes, nice snug fit, both sides.

“Does the pin go into the rear rail just fine by itself?”

Yes.

“Tough to expertly diagnose the issue without seeing it.”

Yes, I realize that. 🙂

“Best I can say is check out ‘MarineGunBuilder’ on YouTube and watch his videos on rear rail fixes.”

Those are the videos I’m going by. He’s the one that mentioned drilling out the ‘U’-shaped rail to get it to fit. That makes me a bit queasy, since that means under firing loads, the rail can ‘walk’ up and down a bit. I would think one would not want that to happen.

I have to admit, JWT’s build here using the the 80% Arms GST-9 kit looks like it is of a higher-quality than the Polymer 80 one I have here. Live and learn, I suppose. Thanks for the advice… 🙂

“…drilling out the ‘U’-shaped rail to get it to fit. That makes me a bit queasy, since that means under firing loads, the rail can ‘walk’ up and down a bit.”

Guessing you’ve done or thought through this part but give it one more go.

Break the rear rail down into its contact points that prevent it from moving up and down.

1) All the underside of the ‘U’-shaped rail contacts with the frame preventing downward movement. It’s not the pin preventing downward movement. Thus the reason you can’t get the rear pin in.

2) The bottom (6 o-clock) position of the pin-hole in the ‘U’-shaped rail contacts with the pin preventing upward movement (that along with the pin’s contact with the frame).

So unless you drilled the rear pin hole in the frame too large, there should be no ‘up’ movement happening by lightly filing the bottom (5-to-7 o-clock) of the pin holes in the metal ‘U’-shaped rail to achieve a very tight fit.

Pretend you’ve already filed the bottom of the pin holes in the rear rail and got stuff to fit incredibly tight as listed above. There would be a ‘minor’ gap at 12 o-clock between the pin and the rear rail and sold contact between both at 6 o-clock. The only possible movement for the rail would be ‘down’ and that’s obviously prevented by the underside of the rail’s contact with the frame.

Using the old woodworking saying of “Measure Twice, Cut Once”, I bought a small round hand file and worked on the bottom of the pin holes in the ‘U’-shaped rear rail. 3 or so light strokes on each side and then check the fit. Doesn’t fit?…..repeat the process. It was tedious but I eventually was able to get the rear pin in but it was a darn tight fit. No up or down movement.

Just make sure you don’t file the bottom of the pin holes in the rear rail too much or you will end up with the situation you’re worried about.

That said, I agree with you 100% that this 80% Arms kit appears to be a lot better made!

I see what you mean now, I’ll give that a go tomorrow.

I won’t modify the hole, just the rail piece. I like how nice and snug the fit is between the pin and the bored holes, and I do not want to screw that up.

You’re right, it can’t go any further down since it’s bottomed out in the first place.

It just would have been nice had the part not needing to be modified in the first place… 🙁

I used RockSlide on one of mine.

https://rockslideusa.com/product/rock-slide-g19-gen-3-upper/

You order the option you want. I went with just a plain jane model.

I’ve had no issues with it.

First in the World Tokarev with plastic frame. Technology and shooting tests:

https://youtu.be/TJb7M-slIEo

I ordered the GST-9 Pistol Frame (supposidly with a G19 and G17 backstrap) and the jig/toolkit combo. I knew going in it would take awhile to get the products I ordered so I can’t fault them for that, however, after a reasonable period of time I began requesting updates on delivery dates. Never got any real explanation just some vague information about how they were filling orders received 8 months previously. The company could do a much better job keeping their customers up to date on the status of their purchases.

My second complaint involves the missing G17 backstrap that I never received. I realize mistakes are made but I’ve tried contacting them on 4 seperate instances about this and have had no response at all from 5D except their auto response when you contact them. I’ve advised friends and family members planning to do an 80% build to go elsewhere for their purchase. The product is good but don’t expect any support if you have a problem. Seems like 5D has zero customer support.

GST-9 Pistol Build Kit gives me shooter a great feeling of control and security over the firearm.

Visit This!! I Brought my awesome speedloader at https://amzn.to/3l4yKQC

Grip Angle With a 1911 style grip angle, the GST-9 points extremely naturally. Combined with a deeper beaver tail than the Glock.

GOT MY NEW SPEEDLOADER AT https://amzn.to/3l4yKQC

You can build a budget model of this for much cheaper now. I acquired the GST-9 MOD1 frame for $150. Added the full size grip for an extra $20. Jig was $25 or $30. Then I ordered the Judah 19 complete parts kit from JSDsupply for $280. Complete gun for $475-$480.

Inspired from the tv series Yellowstone, this Kelly Reilly Blue Coat is poncho-style outerwear. Kelly Reilly portrayed the role of Beth Dutton, daughter of John Dutton in the series.