It was raining hard enough to mistake Ann Arbor for Seattle when we pulled into a nondescript office park in Ann Arbor last month. TTAG and a few other gun writers had been invited to tour the headquarters and manufacturing facilities of EOTech, the makers of the iconic holographic weapons sights used on rifles by law enforcement and military units around the world.

This was a first for EOTech, a company which has always been guarded about its processes and technology given their virtual lock on the HWS market while their patent was in force and because of their extensive government contracts.

Why Ann Arbor?

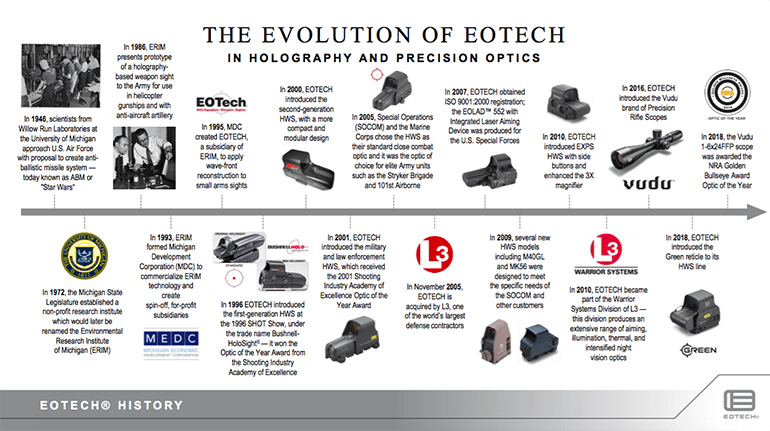

The company’s roots go back to a University of Michigan project in cooperation with the Air Force to develop an anti-ballistic missile system after the end of World War II. That effort ultimately resulted in the invention of laser holography, creating the first holograms at the university in 1962.

Something called ERIM, the Environmental Research Institute of Michigan, was created in 1972. ERIM worked on a number of defense-related technologies such as sighting systems for helicopter gunships, anti-aircraft systems and heads-up displays. As further applications for laser holography became apparent, ERIM established the Michigan Development Corporation to commercialize the technology.

MDC created and patented the first holographic weapons sight (HWS) in 1992. EOTech was founded in 1995 and together with Bushnell, they introduced the first Holosight to the world in 1995.

As the sights and technology matured, EOTech’s HWS gradually won acceptance by the DoD and law enforcement agencies, growing into one of the most widely adopted sighting systems to this day.

The reason for opening up the company to the media is that EOTech — which has been owned by defense giant L3 Systems for the last 13 years — is much more than just a government contractor and has branched out in recent years into traditional optics as well, introducing their Vudu line of rifle scopes first rolled out in 2016.

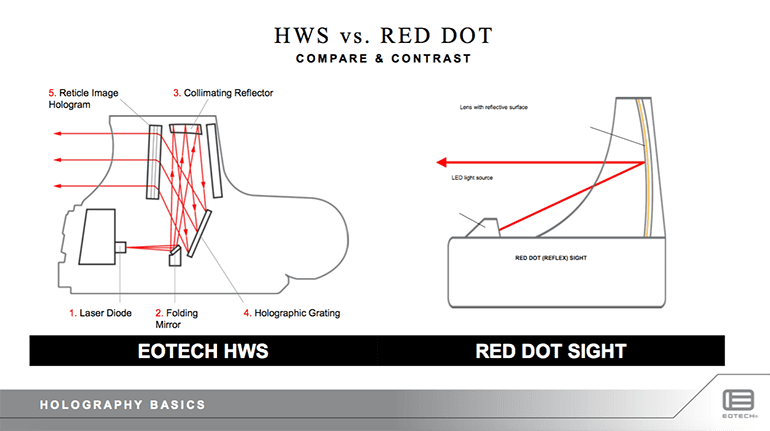

They also want potential customers to understand what makes a holographic weapon sight different from a red dot, something I didn’t fully understand. This graphic helped:

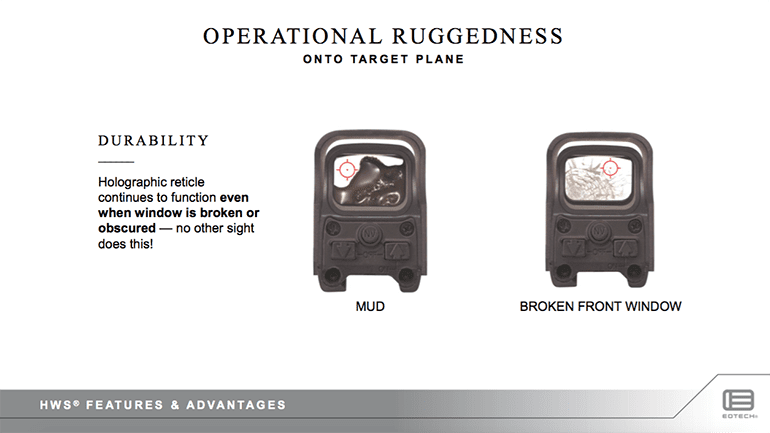

The HWS is much like a mini heads up display (though the HWS is more complex), the kind fighter pilots see or that are increasingly available in higher end cars. The sight uses a laser to generate the holographic reticle. Because the light never hits the front lens, a HWS is still perfectly useable if the front objective, which is there to seal the system, is broken.

A red dot’s LED-generated light is bounced off the objective lens and reflected back toward the shooter’s eye. That means that, at the right angles, the LED is visible from down range — a drawback in a combat situation — where the HWS’s light isn’t projected forward.

The see-though model was helpful in understanding the mechanics.

This sight still displayed a useable hologram.

And because the HWS eliminates parallax, you can be off-center and still on target with a zero’d sight.

Users of EOTech’s HWS had, for years, asked for a green laser version. The human eye picks up green light about six times more readily than it does red light. The only drawback to a green HWS is that it isn’t night vision compatible. But as EOTech found out, it’s not easy being green. There’s much more to making a green HWS than substituting a green laser diode for a red one.

Not only does generating a green laser require significantly more power, but the sight’s standard components didn’t work with green light. The HWS had to be significantly redesigned to generate a green hologram and provide an acceptable amount of run time. EOTech finally overcame those technological challenges and introduced a green HWS earlier this year.

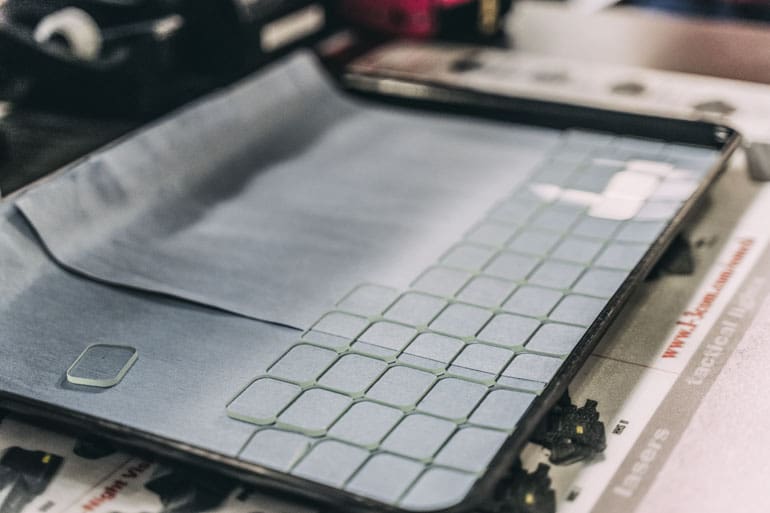

Once we put on gloves, eye protection and lint/static-free jackets, we got to see the manufacturing process. Well, most of it. What we couldn’t see was the actual laser etching (thanks, OSHA). What we did see was the entire assembly process from that point forward including the extensive QA and testing processes.

Examining a tray of etched reticles which look like clear glass until illuminated by a laser.

This line worker does the final zero confirmation and adjustment after assembly testing.

Completed G33 3X magnifiers.

This is one of the final assembly areas where sights are aligned, checked and tested. The man at the back left is attaching six sights at a time to a vertical pistol with six Pic rails. Sights that have been zero’d are then impacted repeatedly — up to 40 times — to simulate heavy recoil, then checked to be sure they’ve maintained their zero.

Completed sights then go to a different quality control area for thermal variation and water resistance pressure testing. Which brings us to the thermal drift issue.

EOTech has completely revamped their quality control processes after the settlement with the Department of Justice. The QC group doesn’t report up through the production side, which eliminates any pressure to pass products in order to meet production goals.

Here’s a point of emphasis that most EOTech customers probably don’t know: the sights sold to the public and those that go to the military are made to exactly the same standards with the same quality and components. The only difference is in the level of QC they undergo. Every single military sight is tested and tested more strenuously (a wider temperature range and greater pressure levels). The commercially sold sights are batch tested.

In fact, due to military contracting constraints, the public gets products with more current improvements and updates long before the military does. That’s due to the laborious and extended approval process the military goes through before approving any change to the manufacturing process. So if EOTech identifies a way to improve the construction or function of their HWS or their G33 Magnifier, those improved products will probably hit your local gun store long before the military gets them.

As for the thermal drift issue, the DoD is apparently satisfied enough that the problems have been solved that USSOCOM awarded EOTech a new $23 million contract for sights in September.

After the factory tour we made our way to a local range for a little quality time with the holographic sights as well as the full range of EOTech’s Vudu rifle scopes.

Alternating between a red HWS and a green sight revealed how much more a green reticle “pops” against a target to the eye.

EOTech likes to say that unlike a red dot, a holographic reticle appears to be down range when viewed. I can confirm that, though I’m not sure whether or not that improves accuracy or effectiveness. But it certainly doesn’t hurt.

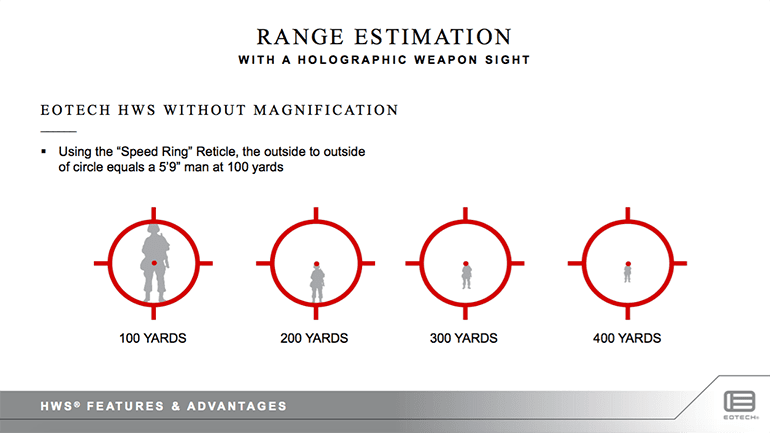

One thing the EOTech “speed ring” reticle can definitely do that a red dot can’t is help the shooter range a target.

This was the first time I’d gotten a chance to try an EOTech sight with one of their G33 1-3X magnifiers. I was amazed at how well they work in tandem.

And of all of the Vudu scopes I got to try, by far my favorite was the surprisingly compact 5-25×50 first focal plane scope which I’d first seen at the NRA convention in May.

Nerd.

Was impressed with EOTech…for a while. But man they ate batteries. After the third time pulling one from the safe only to find a dead battery (both AA and 123 models) I sold them off. Aimpoint all the way baby!

I had the same problem with mine. After the third battery, I began taking the battery out after range time. I do like my Red Dot PRO much better.

Lithium AA’s are the way to go great life, take out after range use….

I wish. Mine is an older model 511. It takes the E 90 batteries.

Love the circle dot reticle… so I got myself a nice Holosun!!! lol

LOL, got a green one my self.

“The HWS is much like a mini heads up display (though the HWS is more complex), the kind fighter pilots see or that are increasingly available in higher end cars. ”

I’m afraid you might be mistaken. Holograms are photographs taken with laser (vs. optical photographs in the visual spectrum). While a printed photograph uses reflected light to reproduce the original image, hologram uses wave constructive and destructive interference to reproduce the original image. (As an aside, the wave at reconstruction must be the same as when the “photograph” is taken to reproduce things accurately in both cases.) The important take away here is that hologram, as used in this case, is static. Their information (i.e., reticle) cannot change on the fly.

Heads up display changes the information on the fly. In fact, HUD is much closer to a red dot sight as they reflect collimated light into the user’s eye. That is because they evolved from the same technology: reflector gunsight used on the likes of P-51.

“That means that, at the right angles, the LED is visible from down range — a drawback in a combat situation — where the HWS’s light isn’t projected forward”

In the defense of red dots, the LED is a very specific wavelength, and the coating on the glass is designed to reflect that specific wavelength while letting everything else pass thru. If they work 100%, you will never get forward emissions regardless of LED brightness. The problem is that the PSD of the LED emission is not a Dirac delta function, so you either get forward light spill, or the coating has enough tolerance to give the world view a tint.

Well Duh!

Cool. I learned something here. I definitely want a holographic sight, not a red dot. Whether I can afford an EOTech is a different story altogether.

eotechs are just not needed. unless you expect to have grenades thrown at you, buy something cheaper.

Most people think that. So did I. All I can suggest is that your try one to see the difference.

I tried an EOTech back in the Obummer era. It could be my eyes/glasses combo but it just was too “fuzzy” for me. It was like the etching was more pits that a clean cut. Did they change that?

Hey Owen you might want to ask the eye doctor to check your eyes for a stigmatism. I have one in the left eye causing eotechs to look fuzy as well

Have ALWAYS used EOTech sights on my carbines, now with the 3.5x magnifier that I move around between rifles.

Have found them to be more durable even than they advertise and the customer service is outstanding. During the recent controversy over ‘thermal drift’ they upgraded my AA battery models to their ‘newest’ technology for FREE.

Have never had batteries fail or drain in the field. I take my batteries out when I put the carbine in the safe.

Dan, I’m surprised you were not clear on the difference in operation between a Holographic sight and a red dot. That’s a .416 Barrett sized hole in your gun sight knowledge.

My experience with EOTech made the highly mission specific. Use if needed, but their significant drawbacks (cost is not one of them) absolutely requires the general consumer to do their homework.

My favorite feature of the EOTech is the huge window. Works great for holo sighting and works great to see the irons after the battery dies. Which it always does.

By the way, that there laser beam? Well since it’s not pointed forward, its pointed into your eye. Can be risky.

“Can be risky.”

Risk is proportional to exposure level. At the nanowatt or picowatt level, you’ll be fine…

While the laser probably puts out a number of milliWatts which could be dangerous if pointed into your eye, look at the diagram. The laser points straight up towards the housing wall. It then scatters off of a mirror, a reflective grating, then a transmissive grating.

Probably only 1% or less of the original light makes it to your eye. That, and the inefficiency of a laser diode, is why it’s such power hog.

good only if your target shoots back ,otherwise ,old school no batteries,.

“This was the first time I’d gotten a chance to try an EOTech site…”

A chance to try an EOTech sight, perhaps?

(Otherwise, great article. Now I want a holographic sight as much as I wanted my MTV in the early 80s…)

Damned homonyms. Fixed.

Everyone makes a big deal about the thermal drift. What about the other issues in the DOD lawsuit? The sights were failing submersion tests as well. The battery issues are also well documented.

Was it EOTech that had the numbers of Scriptures in their model numbers?

Trijicon. Also used to put the verse references on their scopes.

I love my xps2. I’ve had the same battery in it since 2013. I have it mounted pretty far forward on my tavor and I get excellent visibility around my periphery that I dont get with my ACOG.

My only gripe is the size of the dot in the center on a target at 100 yards but I have the tavor for close up fun anyway.

I’ve bought a few used EOTech 512s over the years, prices from $210 to $350. For the cost used to like-new I have no complaints. I also own 2 Aimpoint Comp M2 and a Comp M4, the battery life is definitely superior on the Aimpoint optics, but I’d trust my life to either without question.

What’s their excuse for concealing the problems? Until that’s addressed I won’t buy anything from them. The refund was a good step but not enough. Just my opinion. I know many are fine with them. With companies like Trijicon and Aimpoint around there are alternatives without the troubled history EOTech has. Good to see them trying to rebuild their reputation.

You listed the G33 1-3X magnifiers…..Actually they are 3x NOT 1-3X. I like my Vortex 3x magnifier behind my 512 hws at less then half the cost with life time warrenty.