[This is the second post in a series on 3D printing for producing your own homemade firearms and accessories. See our first post here. Despite the best efforts of federal and state level politicians, making your own guns at home for your own use is still legal in almost every state (some require registration…check your local laws)].

By Ivan the Troll

Now that we have a basic understanding of 3D printing from the previous article, it’s worth delving into what exactly is possible in the 3D printed firearms world – some things are obvious, but some go beyond even the wildest expectations of folks who are new to it.

For those wishing to download files in the background while you read – here’s a link to a listing of Deterrence Dispensed’s tested releases.

Major Printable Firearm Parts

These are a few of the more noteworthy 3D printable ‘firearm parts’ – the frames and receivers that are regulated as firearms in the US. It’s worth mentioning that the estimated cost/lifespan of these parts depends on a number of factors, so the numbers provided are more baseline values than maximum or ideal numbers.

GLOCK 9mm Frames – G17, G19, G26

These frames were developed by the Deterrence Dispensed developer ‘FreeMenDontAsk’. They can be printed in PLA or any better material, cost about $3 bucks to print in PLA, can last upwards of 1000 rounds in PLA, and rely on simple metal rail inserts to retain the slide (though 3D-printed nylon rails can be used for short term applications).

A GLOCK parts kit is required to finish the build, and prices on those vary widely.

Ruger SR9/SD9

These frames were also developed by the Deterrence Dispensed developer ‘FreeMenDontAsk’. They can be printed in PLA or any better material, cost about $3 to print in PLA and can last upwards of 1000 rounds in PLA.They rely on simple metal rail inserts to retain the slide (though 3D printed nylon rails can be used for short term applications).

An SR9 or SD9 parts kit is required to finish the build – these can be had from gunbroker.com auctions or from everygunpart.com sales.

AR-15 Lower Receivers

AR-15 lowers were some of the first ‘firearm parts’ to be 3D printed, dating back to 2012 and even earlier. Many different people have developed working AR-15 lowers – my personal favorites are the Fosscad V5.1 GS and the Warfairy Vanguard. These generally need to be printed in PETG, ABS, or nylon, as PLA is just too brittle to last a long time under the fatigue environment an AR-15 lower is subjected to when firing.

A well-printed AR-15 lower that isn’t abused (not dropped or bent about the receiver extension) will last beyond 2000 rounds. By that point you can have spent more money on ammo than your parts kit.

When printing in ABS, PETG, or PLA, these cost about $5 each to print. An AR-15 parts kit is required to finish the build – I love Palmetto State Armory for their cheap deals and surprisingly good quality AR kits.

There’s just something special about running mags through a sub-$300 AR-15 build.

AKM Receivers

AKM receivers were developed as a passion project by me. There were enough people out there repeating the idea that there are ‘just too many forces involved on AK receivers’ to print one.

DNO Firearms had demonstrated a 3D printed version of their DX-7 AK receiver, but that pattern of AK is proprietary to them and requires a modified bolt carrier. I wanted something true to the AKM (stamped) receiver pattern.

This receiver was dubbed the ‘Plastikov’ as a merge of ‘plastic’ and ‘Kalashnikov’. I got nearly 2500 rounds through my final version of the receiver when printed in PLA before it finally cracked on its side. It costs about $7 in PLA to print and uses metal rails to hold in the bolt carrier and for the shark-fin ejector.

At the time of this writing, I’m assembling a glass-filled nylon Plastikov receiver that should last well beyond 2500 rounds. The current Plastikov uses AMD65 rear trunnions, but can take any headspaced barrel assembly.

I like the AMD65 kits from ClassicFirearms. There sadly isn’t much demand for headspaced AKM parts kits, and they most certainly aren’t competitive with AR-15 parts kits in terms of price.

TEC-9/AB-10 Frames

The 3D printable TEC-9/AB-10 frames, dubbed the ‘Ghetto Blaster’ by their developer, FreeMenDontAsk, improve the reliability of the iconic firearm by converting them to use GLOCK magazines. You can load up your fun-stick and let loose 33 rounds in classic 90’s fashion.

These frames cost around $3 to print in PLA, last well into the thousands of rounds, and don’t require any metal inserts…just a TEC-9/AB-10 parts kit.

These kits used to be very cheap, but since this frame was released, parts kits are going for 5x what they used to. The kits can be found on everygunpart.com or gunbroker.com auctions. Hopefully an outfit will start making TEC-9 parts kits to address the rise in demand these frames have seen.

There are several other printable frames and receivers and more are constantly being developed, tested, broken, and improved over time. These aren’t the only areas progress is being made though.

Printable Magazines and Accessories

One of the most challenging aspects of making guns at home traditionally is making reliable magazines. Armchair gunsmiths will tell you it’s easy to do with a metal brake, but quickly shy away from proving they’ve made reliable mags that way when challenged.

3D printers offer a way to make reliable magazines for unbelievably low prices – as well as some other add-ons and accessories that traditionally sell for far more than you can print them for.

9mm GLOCK Magazines – the Mendendez Magazine Family

Perhaps the most common pistol magazines — the GLOCK 9mm double-stack mags — were a prime candidate for 3D printing. OEM mags are fairly expensive and some aftermarket mags such as PMAGs have compatibility issues with some guns (especially guns with non-tilting barrels).

The Menendez Mag is a solution to this. Printable in PLA, you can have a 17-round G17 pattern magazine printed for 80 cents. Drop in a $2 mag spring from Wilson Combat, and you’ve got a $2.80 magazine that works better than a PMAG GLOCK-pattern magazine.

The printed mags lack the longevity of commercial mags. After around 500 rounds they begin to wear out. But the follower, baseplate, and locking tab can all be reused along with the magazine spring. So for $.60 more you can print another magazine body and be right back in business. Even still, at $2.80 a magazine, you’re looking at reliable magazines that cost less than the ammo they can hold.

These mags are great for homebuilt guns, testing or training use (no sense in beating up your nice OEM ones), as well as general range use. The Menendez Mag is a G17-sized mag, but G19 ‘Mini-Menendez’ (15 rounds) and G18 ‘Extendez’ (30 rounds) patterns are printable as well.

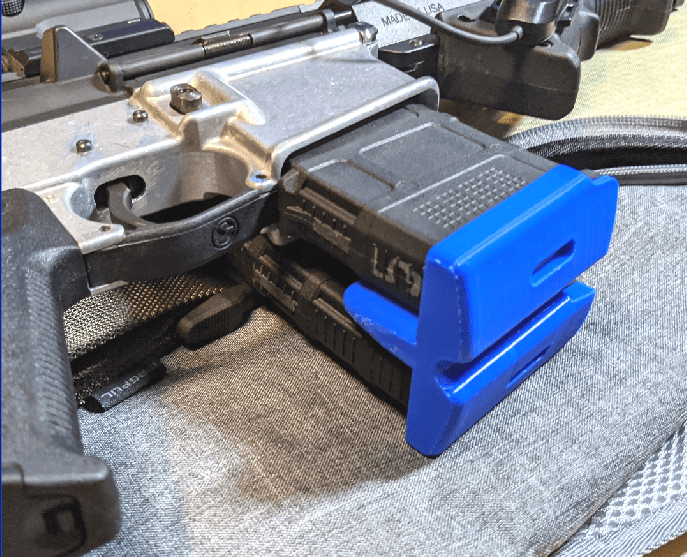

Printable AR-15 PMAG Magazine Couplers

As far as I am concerned, the PMAG is one of, if not the best choice in AR-15 magazines. The magazines themselves are quite cheap, but some of the accessories can get expensive, especially if you have lots of PMAGs.

This is just one example of printable magazine accessories – a baseplate that combines two magazines together, side-by-side. It costs less than a dollar to print, and at the very least is a cheap way for you to try out having stacked mags rather than buying a commercial one for $10 only to decide you don’t like it.

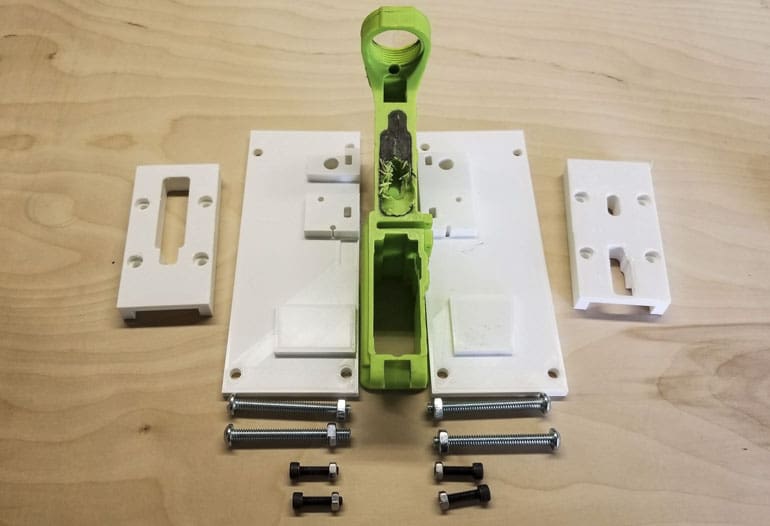

80% Lower Jigs

Another interesting application for your 3D printer is 80% receiver jigs. One of the biggest drawbacks to finishing 80% receivers is the high up-front cost of buying the necessary jigs.

Yes, you can try and lay out the borders of the pocket without a jig, but one wrong move and you’re out the price of a lower and potentially an hour’s work. That’s where your 3D printer comes in. For around $3 in PLA, you can print a jig for AR-15 or AR-9 80% receivers, then finish them on your mill, drill press, or router setup.

As seen in the picture above, some small metal hardware is needed to assemble the jig – nothing too fancy, but worth noting.

I have used these 3D printed jigs myself to finish several AR lowers. Assuming you don’t mess up at all, the jigs are reusable.

If you’re really hogging things out, you may want to consider using cutting fluid to keep the temperatures from cutting friction from melting or warping the plastic, but when doing 0.050” passes on my mill, I only needed a little squirt of WD-40 to keep things cooled off.

(Yes, I know, you armchair machinists…WD-40 isn’t cutting fluid. But it does help with evaporative cooling. If it’s stupid and it works….)

Brass Catchers

Another useful device you can print yourself is a brass catcher. Often overlooked, they help save you the trouble of stooping over to pick up your spent brass, having brass fly past the firing line at a public range, or simply getting lost if you shoot outdoors.

While commercial catchers are fairly cheap, you can print your own catcher and it mounts for less than two bucks.

I sewed up a bag for mine using spare canvas cloth, but a mesh drawstring bag or any heat-resistant material will work fine. If you have CAD skills, you can easily modify the catcher to fit your specific setup – some commercial catchers can’t fit around certain scope/iron sight setups without being too far from the ejection port to properly function.

Conclusion

Hopefully this was useful to help you better understand the sorts of things that can be printed as soon as your first day of owning your 3D printer. Some folks have managed to assemble their printer, dial it in, print a GLOCK frame, built it out, and test fire it in under a week. If you follow the available tutorials you’ll find it’s far less daunting than you may have thought.

In the next installment in this series, we’ll cover the more advanced applications and techniques the budding home gunsmith can use with their 3D printer – everything from rifling chrome alloy steel plumbing tubes to overcoming the weaknesses of 3D-printed parts and pushing the boundaries of what is possible today.

Read Part 1 in this series here.

Read Part 3 in this series here.

Experienced 3D gun maker Ivan the Troll is head of PR for Deterrence Dispensed.

Didn’t think about the jig, I should have kept that freebie printer someone dragged home.

The top picture looks like a Hi-Power, yet wasn’t mentioned in the article. Are we finally seeing some 3D handguns that are not based off the inherently compromised glocks?

I’m not much of a Glock guy either but the 3D printed frames for Glocks seem to work well enough.

For those who are interested this .zip archive has files for 3D printing frames for many popular firearms including the 1911, VZ61, and yes, Glock.

https://archive.org/details/gunplans2019

I’ve been enjoying this series. I didn’t know that a semi decent 3D printer was even available so inexpensively before I read the first article.

I have home-built machined 0% AR lowers, built my own folding and riveting tooling, then built AKMs, assembled FN-FALs from kits, and even a G3. There’s a certain satisfaction in shooting a firearm you’ve built yourself. I might have to give this plastic extrusion thing a try.

Given the number of plastic parts in a Steyr AUG, has anyone printed one of those yet?

And one final comment: that 1/4 inch machine bolt substituting for the rear takedown pin on the AR looks soooo tacky – and somehow wickedly appropriate!

The AUG would require a *huge* 3D printer if you wanted to do anything bigger than the mag release, trigger pack, or handle. I’m also not sure if you could do a stock, mostly because there are some springs embedded in the stock, and I don’t know if you could insert those after the print was completed, or any of the other metal parts like the bolt release. You might have to print two different halves and then weld them together somehow.

That said, if someone *did* make a new AUG stock via 3D printing, that’d be worth the money if it came with some nice quality of like improvements, like forward mag releases and an ambi-bolt release.

“OEM mags are fairly expensive and some aftermarket mags such as PMAGs have compatibility issues with some guns (especially guns with non-tilting barrels).”

Can anyone clarify what PMAGS have compatibility issues with what guns?

A bit late, but some earlier pmags didn’t work in some rifles like cetme pattern rifles and H&K due to their external geometry. They were also a bit thicker than GI mags, so they wouldn’t work in tight magwells. Recent models seem to address that though

I have to imagine you could buy mid-tier hand gun for the price of a Hi Power parts kits.

Of course it’s cheaper. And done legally they know you have it and the serial number on it.

Dude, if they’re monitoring gun purchases that closely (never underestimate the ineptitude of bureuacracy), then what’s makes you think they aren’t monitoring who downloads 3D printer files and purchasing 80% lowers?

Parts can be bought offline, with no trace, and you can hide the trail for downloads, or make your own blueprints. The entire point is defiance. Fuck em.

Oohh…. A 3D printed BHP lower? Yes please. <3

Of course, if I had my druthers I'd just as soon conventionally machine my own Hi-Power on a mill. Build it all from scratch using the blue prints for them that showed up online some years ago. |3

Apparently Cody Wilson himself is now launching what he calls the “Netflix of 3D Printed Guns”, wherein a subscriber paying a mere $50 annual fee will have access to all sorts of files, including first access as new ones become available. There is a variety of interesting things to be made, as of early 2020. Interesting:

https://www.zerohedge.com/technology/states-shutter-gun-stores-amid-surging-demand-rights-activist-launches-netflix-3-d-guns

some one made a vz61 printed lower, but went dark after they posted.

Well, off to EGP to see what kits could be turned into working pistols again!

I can make a firegunm with out plastic.

Can you use more durable material for longer lasting magazines?

Yes.

Could a bullet be printed ala the ThunderZap? These were made with come kind of teflon related polymer and I was wondering if the material used in today’s 3D printing was any where close in properties? Can a 3D printer print the resolution necessary for the precision a bullet would require?

The biggest problem with most 3D printers is they use a plastic filament as the construction material. Some of these such as PLA melt at around 200C (392F). PETG and a couple of others are a bit more at 230-260C (446-500F). Chamber temperatures would be quite a bit hotter. So you would end up with either a melting glob of plastic spewing out of the muzzle, or it vaporizing in the barrel. It’s a mess either way. Also, I would think it would be hard to maintain a consistent bullet weight.

I thought that might be the case, but was not sure of the actual material used or if there was a suitable alternative.

Yes, heat from powder ignition is significantly higher than the melt point of plastic. But bear in mind that heat TRANSFER is not as instant as the powder burn. Increasing heat transfer rates is a primary obstacle to overcome when printing at higher rates. (see: Volcano hot-end) You might scorch the tail end of a bullet, but melting it outright strikes me as unlikely.

From a fouling standpoint, I’d be more concerned about plastic wearing off from the rifling of a barrel than I would be about the bullet melting.

You can print in plastic like PEEK that can handle 500°f (continuous); you can anneal {solid} plastic parts tightly packed in graphite at just over melt point, then electroplate; you can print a precision part, pack in greensand, and use the lost-pla casting method with an Amazon melting furnace. 3d printed tooling for sheet metal stamping, drilling, jigs. there are EDM/CNC metal cutters being made from $200 3d printers, using parts printed on it. The list goes on. 3D metal printers (Direct Laser Sintering and others) are showing up at consumer price points already. You can get 7×12″ bench lathes, Mills, etc, that function plenty well enough for <$1000 on buy now pay later on crap credit. An average teenager could build one in under a week for less (in money & time) than buying one at a big box store. Fact is, technology today has made it so the average person can make a firearm regardless of part regulation, and people across the entire world know it. Good men need to do take stock in this fact – because gun control is a joke to the bad guys now, as the only ones losing the ability to arm themselves are the law abiding, crime is on the rise, and police are underpaid & overworked. Cartels and gangs are printing themselves arsenals, and anyone with some sense could see there's better odds trying to stop COVID-19, and more important things to think about, like this big ass war brewing and the wide open flooding borders. I'm just a simple farmer, but I'm a bit concerned for the world my young kids are growing up in right now.