I was never much of a fan of the AK-47. I had a bit of experience with them in Afghanistan. During my first tour there, the Afghan National Police, Afghan National Army, and the local Taliban all carried the AK as their standard rifle.

I’ve heard all of the myths; that they will run forever without maintenance, that the round is a one-shot, one-kill projectile, and that it’s so simple to use that anyone with any basic familiarization can fight with it. But I watched AKs jam and break.

I treated patient after patient who was shot – sometimes multiple times at close range – and lived. And I watched soldiers and policemen fail to load a magazine, induce a jam, and deadline the weapon during training and in combat. All that while maintaining the ballistics that were similar to my .30-30 at home. And those AK-47s generally shot a 4 MOA groups on a good day. I was not impressed.

And then a round from an AK-74 hit me from around 600 yards away. The tungsten-cored round went through a thin metal door, skipped off my side plate, and slammed into the thigh of the guy behind me, shattering his femur. I had to rethink the accuracy of the platform, and, in my ignorance, chalked it up to the differences between the 47 and the 74.

My disdain for the gun also grew out of my culture. I grew up in the age of the Soviet Union as a real threat. My dad had been an infantryman, and I was a total arms nerd. Not a gun nerd, an arms nerd. As a 5th grader I even subscribed to a DoD newsletter that simply published lists of US arms stockpiles and compared them to estimated soviet stockpiles. I memorized those lists. So I always saw the AKs in the red column, the weapons of the enemy.

Suffice it to say, my experience with the weapons was not a positive one.

Five years after I came home from my second tour, another 82nd Airborne solider, Lee Johnson, stood at the range at my house shooting an AK. An AK he made himself. He had a couple of them and we both took some time shooting the steel.

These guns didn’t feel like the guns I shot in Afghanistan. These guns were fun. The recoil was minimal, nothing was rattling around, and the gun felt good in my hands. They never skipped a beat, and they were far, far more accurate than anything I had shot in Afghanistan.

And he made them in his garage. After a few hundred rounds I was convinced. I was going to be build an AK, the weapon of the enemy. And Lee was going to show me how to do it.

Lee, his brother Travis (a fellow 1st Infantry Division combat medic), and Gabe Harris own a little company down in Cypress, Texas called the Dead Goose Society Manufacturing Co. where they teach people how to build all manner of AK platform guns.

Prior to our arriving, I asked Lee what his recommendations were on what kind of gun to build. I wanted a rifle in the style I saw so often in Afghanistan. That is, a side folding metal stock, wooden furniture, stamped metal AK-47 with a standard 16″ barrel.

Lee pointed me to the “Khyber Pass” build kit at AK-builder.com as an option, and it looked like just the ticket. TTAG’s managing editor Dan Zimmerman picked a fixed stock polymer furniture model of the same barrel length. Both were in 7.62x39mm.

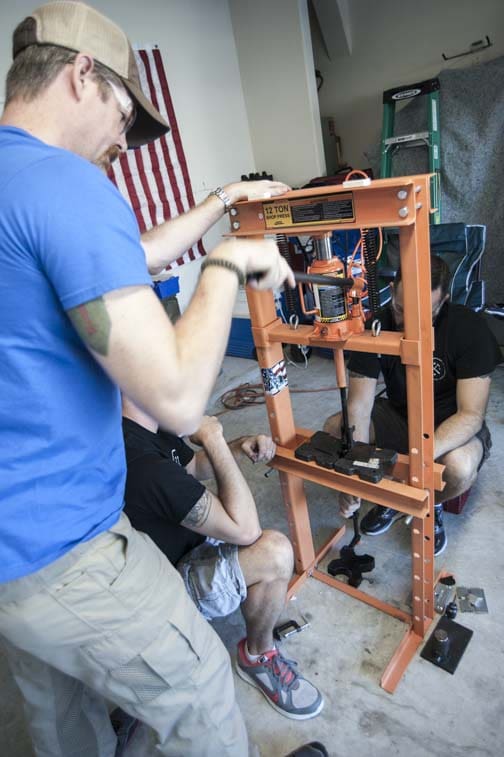

Dan and I met the DGS team at their shop — AKA Lee’s garage — at 8AM Saturday morning. The shop was pretty basic, and that’s what makes building the AK amazing. The tools consisted of a simple 12-ton shop press, a drill press, some calipers, a spot welder, propane torch, Dremel tool, a mallet and some files.

It didn’t require the myriad jigs, fixtures, and molds that DGS had already made or purchased prior to our arrival, but they sure made the process easier. The additional, absolutely required aspect of the process was the experience that the members of DGS brought to the table.

Teaching these classes, usually on a one-student-at-a-time basis, they’ve taken dozens of people through the AK build process. They’ve seen just about every variant, configuration, and condition there is. Which was a good thing for us, because we definitely needed that experience.

I’m used to ARs. I’m even used to “building” ARs. Even starting with an 80% lower, the AR is pretty exacting, and very standardized. When you buy components, you know exactly what you are getting. Not so with an AK made from “demilitarized” parts and what otherwise appears to be scrap metal.

The kits received may, or may not have all of the parts (mine didn’t). The parts may not match at all (Dan’s didn’t) and they may have had some previous modifications that made their reassembly impossible (again, like Dan’s).

What they don’t include is the part our comrades in the central committee known as the BATF actually call a gun – the receiver itself. For that you get a sheet of steel that’s drilled in a few places. Maybe those are the right places, maybe not. And maybe you just have to start from scratch with a blank piece of sheet metal, again, like Dan did.

Either way, this piece of metal isn’t anything close to resembling something as complete as an 80% AR lower. These look like they range anywhere from 0% to 20% receivers to me.

The great thing here was the attitude of the DGS guys. There were several times that I thought that Dan was going to leave without a gun. But in every instance, the guys simply found another way to build it.

They used another other part, modified it with a drill or a file, from some other gun, or just built something from scratch, to make the build happen. Failure was simply not an option. It felt good to be around a group of people who think like that. It epitomized the weapon, the culture that created it, and the culture building it right now.

The first step was the actual building of the receiver. Using DGS’s fixtures and the shop press, the steel is simply laid over the mold, and pressed down, bit by bit, until I heard the sweet double “pong” of the steel as it took shape. Then more measuring and drilling holes, and now I have a gun.

Wait…what? This bent piece of freshly stamped metal is a gun? According to the law, yes. Madness. After the stamping came the trimming and spot welding of the rails onto the receiver. This is another step that was so different than the AR platform.

The rails are pretty much eyeballed in. Travis used a 3/16″ drill bit to space the rails and hold them parallel. How did he know it would work? Lots and lots of experience.

And it works perfectly. Because Dan and I were building different versions, we each had to drill and cut our receivers a little differently, and since I had a folding stock, I had to add a reinforcement plate to my receiver.

After that the center support was put in, and using a propane torch and a standard kitchen oven, we heat treated the “guns.” All of that sounds simple – and for what we are doing it really is – but it took us about five hours.

I bring that up to point out that nothing in the AK build process is perfect, nothing lines up just right, and everything takes a little finesse, often with a mallet. If everything was so simple, as it is in an AR build, the process would have taken two hours, tops. But it’s not. You are actually building a gun here, not just assembling one.

After a lunch of fajitas and beer, (Shiner’s Prickly Pear is not bad at all, BTW), I took my receiver out of the oven and marveled at its golden shiny goodness, and got back to work.

Now the tedium sets in. So many rivets, carefully pressed, using the 12-ton press, one by one.

The barrel was then pressed into the receiver and the headspace was set using Go/No-Go gauges.

For me, this took a while. The back plate DGS uses for pressing the barrel in had apparently walked off with someone, so they rigged it up using a wrench instead. Again, the DGS guys just made it work.

But this meant that as the barrel pressed down, the wrench would flex. The additional variable in the process greatly added to the time it took, and it was about an hour before I could get my barrel headspaced correctly.

But it was so worth it.

Because now I had a receiver, a stock, and a barrel. Now I had what I could recognize as a gun.

The rest of the build was straightforward, but not short. More extractor trimming, trimming and fitting of the magazine well, installing the trigger and the furniture.

Somewhere in there we ate pizza for dinner. I realized I had run into a little bit of a problem because it turns out I had riveted my forward trunnion onto the receiver about 1/16th of an inch too far back.

Not a problem. I simply had to use a file to remove that same amount from everything behind the receiver to make it fit, including the center column support, the magazine well, and the magazine latch.

Try that with an AR!

Finally, I put the trigger in place along with the safety and then…the moment of truth. I put the bolt assembly in, next the spring, finally the dust cover (which I had to grind a little to fit) and function check the gun.

The action was catchy, hard, and rough. But the gun cycled. When on safe, pressing the trigger made nothing happen, with the safety off, I heard the loud smack of the hammer on the center column support.

Racked back and forth a hundred times or so, and the action smoothed right out. I had a working, functioning AK-47. It took 15 hours to build.

Outfrigginstanding.

And thanks to all the adaptation and McGyvering, somehow Dan had one, too.

The next day I went to the range with my gun. The gun you build yourself really is your gun and always will be, and it was a pleasure to fire it. Travis had told me to put one round in the magazine and fire it. Then three. Then a full mag. This didn’t seem in keeping with the spirit of the build, or the gun, or me.

Instead, I sprayed some RemOil into the gun, loaded up six 30 round mags and rapid fired them all as fast as I possibly could. Zero malfunctions. The gun cycled flawlessly, kicking steel cases from the surplus TulAmmo high into the air.

At the bench, using bags and the super-short sight radius on the stock AK sights, that same surplus ammo printed consistent sub 2-inch groups at 100 yards. I was floored.

I expected twice that, at least. This was as good as I could shoot my old Winchester 94s, if not better. I now have a folding stock truck buddy, a compact, light weight, semi-automatic .30cal that I can reliably take native game with out to 300 yards.

The next day I put another six magazines through it with more surplus ammo. Again, zero malfunctions and it’s holding that sub 2MOA group. The metal stock, with no padding and some sharp angles, does dig into the skin after a couple hundred rounds. It’s not very comfortable to get a cheek/stock weld on. The safety latch bites into my palm if I slap it down hard. In rapid fire, it’s hard to keep the gun firmly glued to my shoulder.

And yet, somehow, the rifle still feels great to shoot. I just did a video shoot for a TV show, and I could have used any of my ARs, some of which are half MOA guns, with custom Cerakoting, $1,000 glass, QD silencers and $200 triggers. But I didn’t. I shot my AK. Because that bolt carrier slides on the rails like butter now.

It gets better every time I fire it, and the gun is just so damn fun to shoot. And holy crap I made this thing with a bunch of dudes in a garage on a Saturday!

Over the years, I’ve spent a good amount of time, if not enough of it, in machine shops making all sorts of guns. To me, nothing embodies the sense of hope and possibility like a machine shop.

But that weekend we made that process smaller, simpler, and did it among friends. A group of friends, some fellow veterans, worked all day to make what was, at least to me, the weapon of our enemies. And that left me feeling like we hadn’t just spent the day building a rifle, but celebrating the values I most cherish about our nation.

We took ahold of the very weapons used against us, remade them, and used them to feed and protect our families. We did it using what was on hand, what we could find, and what we could make ourselves (with a lot of help from some very skilled instructors).

It was a great day, building a great gun. Thank you to all of the good folks over at the Dead Goose Society for giving me one of the most American experiences of my life.

>> that the round is a one-shot, one-kill projectile

This is the first time I hear such a myth. There’s one that says that it’s a more potent round than either 5.45 or 5.56, and there’s certainly a lot of debate around that, but I have never heard anyone claim that it’s a “one kill” projectile. It’s fairly obvious that it’s not, given that it’s less powerful than full size rifle rounds of WW2 era, and plenty of people have survived being shot by those.

Bro, do you even internet? I kid… I kid. The AK crowd are a pretty headstrong group and I hear mythical claims of the ballistic properties of 7.62x39mm often. One shot kill may be hyperbole, but deep down inside, i have a feeling they really believe it.

I’ve actually been pretty interested in the 5.45x39mm ballistics as of late. What first piqued my interests is discovering that it has a higher ballistic coefficient than 5.56x45mm which is the first clue that it may in fact actually be a more accurate round. But if you ever see ballistic gel wound channels of 5.45 ball ammo vs 5.56 ball ammo, the 5.45 looks like it leaves some pretty gruesome wounds.

This is one other of those never-ending debates. The thing about 5.45 (at least the mil-spec stuff) is that it does not fragment. It does, however, tumble pretty violently. 5.56 tumbles less, but some types of bullets (notably the original M193, but also e.g. Mk262) fragment very violently up to a certain range. Fragmentation creates a larger permanent wound cavity all around, but just how much you can rely on it to happen is disputed.

M855, on the other hand, is the worst of both worlds in that it neither tumbles early nor fragments except at very close ranges, esp. out of a carbine barrel…

As far as BC goes, it depends on the bullets again. I don’t think 5.45 would beat the BC of Mk262, for example. Then again, the cost ratio is 3:1.

5.56x45mm was never a ‘kill’ round. It was a wound you bad enough so that your buddies dragging you off the battlefield would kill you to stop you from giving away their position. The RBT was designed to make the round tumble (bad wound from a Geneva Convention approved round).

I like the 5.56x45mm for the mere fact I can carry more. The more 5.56x45mm I carry, the more 7.62x39mm there is lying around to pick up.

>> 5.56x45mm was never a ‘kill’ round. It was a wound you bad enough so that your buddies dragging you off the battlefield would kill you to stop you from giving away their position.

Now this is actually a myth. If you read about Project SALVO, that was not their intent at all, and in fact they’ve noticed the devastating effect of fragmentation on tissue very early on. It’s largely why the initial Stoner design had 1:14 (!) twist rate – because understabilized bullets, while less accurate, tumble (and hence fragment, at such velocities and given M193 bullet design) very reliably. The Army requested that the twist be reduced to 1:12 to improve accuracy amid concerns that it wouldn’t be good enough in abnormal environmental conditions (humidity, pressure etc).

The “wound not kill” is an ex post facto rationalization that someone (I don’t think it was even the military) came up with when it became obvious that M855 specifically had really crappy terminal ballistics.

Soviets definitely never bothered with such concern at all.

>> The RBT was designed to make the round tumble (bad wound from a Geneva Convention approved round).

I’m not sure what RBT is, but Geneva convention doesn’t regulate things like that; you must be referring to Hague. But Hague doesn’t prohibit tumbling rounds, either. What it bans is “bullets which expand or flatten easily in the human body, such as bullets with a hard envelope which does not entirely cover the core, or is pierced with incisions” (full text here: http://avalon.law.yale.edu/19th_century/dec99-03.asp – it’s very short). So hollowpoints and softpoints are a no-no, but tumbling is fine, and fragmentation is unclear (it could be argued that a fragmenting bullet does “expand”).

As int19h said, its a complete myth that the round was designed to wound. At int19h, the interesting thing is where the whole 5.56 is effective due to tumbling comes from. Early reports of the excellent terminal ballistics of 5.56 were initially classified, and the rounds effects were stated to come from tumbling instead of fragmentation due to concerns of the Hague convention. Couple this with the introduction of faster twist rates and the horrible 855 gave rise to the tumbling wounding rumors of 5.56

SALVO – https://en.wikipedia.org/wiki/Special_Purpose_Individual_Weapon#Project_SALVO

didn’t go after a “kill” round. It went after a weapon that could deliver many rounds downrange in the hopes that more of them might be delivered on-target with the overall effect being greater lethality.

RBT = Rebated Boat Tail – end of 5.56 / .223 is to make the round ‘tumble.’

I concede the Hague point, always trip up when I think about the squishy-feely side of war.

Yes, SALVO didn’t specifically go for a killer round. But neither did they go for a wound-not-kill round. And when they discovered that light, fast rounds really do fragment like hell, causing massive wound cavities and gaping exit wounds, they duly noted it in their reports as one of the side benefits.

If you’re going to footnote wikicrapola you need to do so a some braindead sight (something demtard would work).

At Joe R. All spitzer type bullets tumble by nature. I would love to see where you are getting this data that RBT bullets enhance tumbling. They enhance performance of a round via its end internal ballistics and its external ballistics.

You stated “It was a wound you bad enough so that your buddies dragging you off the battlefield would kill you to stop you from giving away their position”. Which is simply false. While Project Salvo found more projectiles fired is better. Multiple other postwar surveys into terminal ballistics found that smaller rounds moving faster had better terminal ballistics than the current rounds in use. These wounding characteristics came from fragmentation. The 5.56 wounds that were documented by early US advisers and special operations forces in Vietnam also back this up. They found that the M16 had better terminal ballistics at the ranges they were engaging at than the M14 it replaced.

Wait, my first line was somewhat toungue in cheek, the 5.56 was not designed to do anything but ‘damage’ you (as badly as possible to hopefully kill you, but not AS likely individually). Which is where the multiple rounds down range principal comes into play (yes the wiccan pedia sucks but it’s generic enough no one claims indelible bias. But wicci cites the SALVO report as being in response to 1:10,000 “hit” ratio of standard rifleman weapons of WWII. Sounds somewhat skewed, but I defer). A BT (boat tail) or RBT (rebated boat tail) is for external ballistics [helping overall bc like a double-taper in a football] (spitzer type) but yes, the BT was a way to make the (otherwise ball) bullet tumble in terminal ballistics and mostly do the job of framenting ammo even if it didn’t fragment.

Terminal ballistics x range is what’s key. Transferring energy is what it’s about. The smallish 5.56 does not have as much mass, push it fast = good, but small thru and thru hole in target = bad, so the tumble.

@Joe, you are just digging yourself deeper. You keep mentioning Rebated boat tail ammo. What 5.56, 7.62×39, 5.45×39 have a Rebated boat tail? Can you honestly tell me what a Rebated boat tail is without looking it up. How is RBT or Boat tail bullet going to tumble better than a non RBT or BT spitzer bullet?

You said “5.56 was not designed to do anything but ‘damage’ you (as badly as possible to hopefully kill you, but not AS likely individually)” As likely as what? The 7.62 Nato or 30.06? Cause that goes against all the live tissue test, and real world validation that showed at typical infantry ranges the 5.56 was more lethal than the rounds it replaced.

BT= rear tapered

RBT = rear stepped tapered

Not aware of any NATO (rifle) rounds that are not BT

Many, if you mic ’em, are slightly rebated in mfr. not able to speak more on that .

Anything not an ‘infinite’ ‘rod’ will (when imparted with any angular momentum on impact [unavoidable]) tumble.

5.56 rounds are only ‘as-good’ at infantry combat ranges and have plus/minus ratings on penetration etc. Main benefit, smaller and can carry more.

It doesn’t really make sense to talk about “5.56 rounds” in general. It all depends on the specific round. There are many that are better than standard issue ball .30-06 and 7.62×51 that preceded 5.56, especially under 150 yards or so. The stuff that they were originally testing in the 60s (i.e what became M193) does reliably better with the original 1:14 twist at practical engagement ranges in most environments.

Great write-up, and a great gun by the looks (and shots) of it.

Agreed. Fascinating and outstanding article. Thanks.

Ha! Soo Dan finally got an AR, now he has an AK to boot.

And it shoots, too!

Which one do you prefer shooting?

I love the AK because I built it (with a lot of DGS help). But the AR I now have is one HELL of a nice gun. It’s basically this one:

http://www.undergroundtactical.com/products/bacon-maker-baller-556-vietnam-tiger-stripe-custom.html

upgraded with the top of the line Magpul stock (no tiger stripes). I have to give the edge to the AR.

” But the AR I now have is one HELL of a nice gun. It’s basically this one:”

Wait…

Spiral barrel fluting and all?

Nice Дух пистолет comrade!

No idea what you wanted to say, but it’s not meaningful Russian.

I think he went for a ‘ghost gun’.

@Geoff Yep, spiral fluting and all.

That was a fun write up. Thanks JWT. The real problem with AKs is actually the same problem with ARs… once you have one, you need more. Looking forward to your writeup of your AK74/5.45x39mm build coming up around the corner.

Ha! I’m already jonesing for my next AK. But for this one I want a folding stock SBR. Trying to figure out how to legally do that, and technically do it as well.

Agreed. That was really cool.

I’ve got to look into something similar in my neck of the woods.

I’ve never really wanted an AK, but if I built one like this? That would be a keeper.

Great write-up and thanks for the excellent article! Just as an FYI, it is AK-Builder.com, not AKbuilder.com (which like AKbuilders.com may just land some spyware on your PC).

Sorry about that. Thanks for posting the right link. JWT

Very nice read. It’s got me itching to make one. Definitely agree a machine shop is a place of hope and promise and all things new. Thank GOD he let’s us take part in such crazy greatness.

Wish I heard about Dead Goose before you posted it here ; D

But, I guess I’ll just have to get in line. 🙂

“This is another step that was so different than the AR platform.”

Friendly advisory:

This is why “different than” sounds so goddamn GRATING to most ears: it’s just wrong. Thank god.

I appreciate the friendliness, but I have no idea what you are talking about.

I believe I would put that press on top of a short table or a pile of pallets or something to get the business end up to eye level. Who wants to work squatting and kneeling? Just sayin’.

It’s hard to beat a day in the machine shop with pizza and beer to create something uniquely your own that will ring steel at 200 yards. Thanks for sharing!

A pile of pallets? You’re in a machine shop, man, build something to raise it up!

Outstanding article. Really enjoyed this.

H-frame presses are like that. Cheap H-frame presses from Horror Freight are even more like that.

The H-frame presses that bring things up to eye level (in general) tend to be very tall, and need very wide feet. The all need a hydraulic press or cylinder up above the anvil bar, and they usually have a piece of round stock pointed straight down.

I have that exact same press. It’s a POS, but it works. And it’s cheap. One day, in my copious spare time, I’ll build a replacement.

Yep! I bought mine for $70 as it was returned by a customer, but it is VERY handy for many tasks as I build cars too!

Ignoring the recommendation of loading 1 round, then 3, then full mag was pretty stupid. On any home build you never know if its going to go full auto and keep cycling since you have zero basis for what tolerances you built into your gun. I nominate you for gun idiot of the day.

“Ignoring the recommendation of loading 1 round, then 3, then full mag was pretty stupid. On any home build you never know if its going to go full auto and keep cycling since you have zero basis for what tolerances you built into your gun.”

He’s had plenty of time with full-auto on multiple platforms thanks to his combat tours in the sandbox.

“you have zero basis for what tolerances you built into your gun” Elliot, I want you to go ahead and read that back to yourself out loud.

The gun I build myself is the only gun I know the tolerances of.

Have you decided on the finish yet?

Something simple like a media blast and phosphate parkerize, or Cerakote?

Ever since I saw that ‘Shovel AK’ photo set I’ve had a Jones to try a build like that.

Maybe a side-folder shovel AK…

Got the Dead Goose guys bookmarked.

“Have you decided on the finish yet?”

Yes, exactly as it is now.

How do you preserve the metal? Inside/outside.

BTW – TX also has Angel Sword and they are supposed to be crazy good @ heat/cryo treat. Would like to press a receiver and get it them withh some of the action parts (barrel cryo?) to see if it made any difference to the +.

Haven’t decided what to do with mine. Though I kinda like the current third world look it has.

Ah, yes.

The gun version of a “Rat Rod”…

Awesome! Love this piece, and I especially love the made-by-hand-in-a-3rd-world-basement look of Dan’s AK. However, I recall not liking that beer… 🙂

Funny thing is,the round that his you was probably not aimed at you, nor did it come from a well maintained and well zeroed weapon handled by a well trained marksman. I’ve always thought it ironic/tragic that you might be killed or maimed in such a fashion, considering the contrast of the amount of money and training invested by comparison.

I would usually agree with you. But the improved penetrator round in 5.45mm, used in Gazni at the time, was used primarily by Chechen fighters that came down for a winter break of hunting the “crusaders”. They were fairly well trained, with well maintained weapons, and since it was one shot aimed at the door I was standing behind, I, or the other man, were most likely the targets.

ok so… MONEY?? how much does the attendance of the build party cost? Elephant in the room to me… nobody else seems to see it.

Yeah, I’m curious too.

About $500 for the instruction and the tooling, plus whatever your particular materials costs is. In our case, they added parts that were broken, wrong, or missing without additonal charge. Usually students shoot the gun there on day two and work on any issues that might arise. We knocked it out in one long day of freedoming.

That was the cost for both of us. Guessing someone from DGS will jump in here and give you the straight scoop.

Just seems like a cool idea. Like the thought of going to the ‘class’? With someone else almost competitively? Very empowering. Like the old saying “give a man a fish, he eats today, teach the man to fish, he eats everyday. Teach the man to fish with dynamite and eventually … you might have to give the man a chicken.”

Good skills to pass down.

A used spot-welder would run you more than that. ?

Well written and entertaining article. Love your passion. Thank you for your service sir.

Sounds like it was a lot of fun. I had 2 AK’s from way back around the turn of the century while they were still cheap and I was a bit more affluent. Wish I had kept them. Dead Goose Society, eh? Why do I have a feeling I’ve got yet another gun project to shop for when I don’t even have the money to finish the ones I’ve already got going 🙂

Tom

Outfrigginstanding, indeed, Jon. Great article, and I’m sure it’s even more fun than it looks (and it looks like a hell of a lot of fun). How much does such an experience cost, though? Fifteen hours of someone else’s time can’t come very cheap.

Don’t let the Feds find out… They’ve been saying for a while that running these ‘build parties’ makes you an illegal gun manufacturer.

That said I wonder if anyone’s actually thought about making guns like this from SCRATCH. Get one person that knows ho to build trunnions, another for bolts, one for barrels, etc. But everyone would probably have to build their own receivers to keep it up on the ‘up and up’. Or at least as tight to the word of the law to make it work. It would take a lot of doing there but I image there’s enough people out there that would be into it.

I have a Bulgy underfolder kit and a CNC warrior milled receiver for it. I need to build it but lack a few tools. It will be stock with the lovely bakelite furniture. Almost as cool as beaver barf!

I also have a Bulgy 5.45 rifle kit with poly furniture. I will be using my Troy long rail for it along with a US length stock and magpul grip. I have two Saiga rifles that are converted and modified and really like them. The AK market has greatly improved since I bought my Saiga in 2007.

SKS Forever!

But seriously the AK is a decent rifle, I prefer the SKS because of better accuracy but I’m still going to build an AK myself eventually. Either way congrats on the AK! 🙂

It’s not at all a given that any particular SKS will be more accurate than any particular AK. The only thing that’s really more accurate about SKS design is sight distance, but you generally don’t see them in good enough condition that it would contribute much if anything to the rifle’s inherent accuracy. In any case, put a scope or a red dot on AK, and that advantage disappears.

Do you like the looks and compact size of an AK, but wish it had SKS innards? Look no further than the Czech VZ-58!

It’s like someone left an AK and an SKS alone in a gun safe for too long. It’s okay, though, because their bastard child is probably the best design of the 7.62x39mm milsurp rifles.

I would actually somewhat disagree that Vz58 is an AK/SKS crossover. I mean, it has some features of both, but its locking system, which is arguably the most distinctive feature of a firearm, is unique and doesn’t really resemble either gun – the bolt neither rotates nor tilts, instead they have that thingy between the bolt and the carrier that tilts. I always wondered why no-one else has used that in a rifle.

The tungsten-cored round went through a thin metal door, skipped off my side plate, and slammed into the thigh of the guy behind me. But…Presedente Obonzo and the BATF said those were illegal. so you are obviously lying. The Taliban would never do anything illegal.

There was an amusing thread on Russian gun forums when someone posted a well-known myth that “AK can punch through a railroad rail”. This was generally assumed to be a myth with no basis in fact, so one of the old-timers on the forums balked at it and said he’d pay $100 (if I remember correctly) to anyone who would actually demonstrate a penetrated rail.

Well, guess what, the other guy picked up a challenge. They have agreed on the terms: it should be a standard railroad rail, and the part that has to be penetrated is the web. Penetration should be complete with the round not stuck.

They tried shooting it with regular ammo first, and, as expected, it wouldn’t do much. After experimenting with various exotic stuff, they have finally obtained some of those tungsten rounds. And so, behold:

http://s00.yaplakal.com/pics/pics_original/4/6/2/205264.jpg

Ya, AK drillbit round. Sabot? Either way, bad news.

everything takes a little finesse, often with a mallet

Finally, another guy who understands the meaning of finesse.

Ha! Mallets are for pussies, finesse is a 2lbs ball peen hammer.

A hammer and an empty bottle of Vodka: AK Armorers’ kit.

When you by components, you know exactly what you are getting. I usually do better when I buy components versus by them.

Nice article. So now I can build a ghost gun with an overcapacity 30 caliber clip that can be emptied in half a second. The shoulder thingie does not go up however.

I knew I forgot something!

Count me as appreciative of this write up as well. Great job. This is my favorite kind from TTAG. Not that I don’t also appreciate the majority of the rest of the content from this blog.

Glad we have another convert builder. Hi, my name’s Chadwick and I have been building for about 1.5 years now. Good times and it is funny to explain to people.

In my experience shooting 5.56 AK and AR side by side it is really hard to discern an accuracy difference between two rack grade examples.

It have build a couple in my garage with minimal tools, but some things are just required IMO including drill press, quality metric drill bits. No press and bolt cutter riveter does just fine.

Wait a minute, if I stamp and form a piece of metal right, according to American law I have a gun? Then why couldn’t I shoot anyone in the handicraft class ( I hope that is the right translation) in school when I was younger?

On an ak it is the fire control group and bolt carrier group mounting ability that makes it a firearm

Okay, but in an AK this are just shaped bits of metal or did I get a wrong impression?

So you could basically have a gun, if you form the metal right, even by accident.

“Then why couldn’t I shoot anyone in the handicraft class ( I hope that is the right translation) in school when I was younger?”

In the USA, the terms are usually ‘shop class’ or ‘metal shop’.

I’m familiar with those two, there may be others in different parts of the country…

Ah thanks, shouldn’t have trusted google translator.

I used an AKM my first few months doing private security work in Iraq in 2004. A definite POS to me, but, hey, you work with what you have. After that I used a variety of guns from Bushmaster SBRs to AKs to Colt M4s, FNs and even a Sterling.

You use what you have.

Years later, working in Afghanistan and Pakistan, this article reminds me of the dirt hut workshops in FATA where people build what they need and can’t buy. I currently own 3 M4s and a WASR AK pattern. All are fun, and I would take any of them into a fight.

It would be fun to build an AK from scratch someday.

JWT-

Bare (but kinda annealed) carbon steel, just an oil wipe on the internal flats?

If you run corrosive ammo through it, what’s the drill?

In the shower for a major hot water flush, shake it out and then out in the sun to dry?

I can see keeping the raw look, but no corrosion control on the internals?

I built one from a parts kit at the beginning of the year, and even though I have quite a few other “higher end” rifles with nice glass somehow that AK always makes me giggle more ringing steel at 200yrds with a red dot or iron sights. I have built a handful of AR’s and done lots of custom work on most of my firearms but somehow that cheap, dirty(AK no need clean comrade!), AK is kinda my baby now and just my go to grab rifle.

OK, you’re going to shame me into it. Next spring, I’ll build an AK. I’ll have to do it out of sight of my wife and friends, so as to not compromise my reputation for being a discerning gunsmith. but you’ve made this look too easy.

It’s so easy, even a caveman could do it.

No, seriously, guys who live in caves build AKs, so can’t exactly be space age.

As I keep telling the anti’s, making guns “is not rocket surgery.” Making nice guns is a matter of craftsmanship and attention to detail. The old Brits in Birmingham and London made exceedingly nice guns with mostly hand tools. The receivers on five-digit “best guns” used to be made from a forging with minimum milling, and a whole lot of work with a cap chisel and hand files.

Making super-accurate guns requires some real skill as a machinist (especially in the making of a barrel) and some reasonably serious metrology in the setup, so let’s make that proviso here. But if one reads of HM Pope’s activities 100 years ago, we can see accurate barrels can be made without computerized machines and with hand-made, hand-sharpened tools.

But making a gun that can “hit a minute of man at 100 yards?” Pfft. The reason why people think it can’t be done with hand tools is that they have no idea of how to really use a file, or use the right file, or that there are hundreds of types of files out there – not just the three you see the tool aisle at Home Depot. I could write a text of over 200 pages on hand files alone. It might seem overkill to people who have never been around files, but once you really know hand files and how to drive a hand file, and you have a good vise… the things you can accomplish will amaze and startle most everyone. Sadly, the biggest name in American files has outsourced their production to the third world, and the resulting tools feel like third world output. So we have to pony up big money for files from Switzerland, Germany, rasps from France, etc. Big money. There are some rasps I’m ordering this month that run $80 to $150 each. For a single wood rasp.

The incessant whinging and furiously petulant foot-stomping of the anti’s has finally pushed me to the point where I’m going to start writing a modern book of gunmaking for people with limited tooling and limited experience. I figure if I sell PDF’s for $5 a download, it might cover my time and materials for the photos and possibly videos I do in the process.

Once there’s a book that walks someone who has no clue how to use tools through the complete process of obtaining the starting tools, making the specialized tools, then making a handgun, a rifle and a shotgun from (mostly) scrap steel(s) starting with relatively common tools, the anti’s can either shit themselves or go blind, I don’t really care which any more.

It’ll probably take me 5+ years to complete, but a man’s gotta know his limitations and I might as well get going on this before I’m senile, drooling and waiting for my blonde nurse with a pneumatic chest to wipe my posterior.

The art of the file was first shown to me when I started blacksmithing. People are inexplicably impressed when you make a knife from a file. I’m a lot more impressed when you can go the other way around.

Also, where can I pre-order the book?

Sign me up! Do I qualify for the limited edition signed .PDF?

DG, I will cherish this moment in my heart forever.

I have a lot of fancy, expensive guns. I like my Saiga .308 best, even above the AKs I’ve built. Kalishnakov action, thumping .308. If I could only have one gun, it’s the one. Never malfunctioned with all the crappy ammo I’ve used in it. I’ve never even cleaned it. Oh, and the bump stock I put on it is a hoot… The 16in barrel version, which I have, is more accurate than the longer barrels, because the longer barrels were made of crap. I used it in action rifle once. I had little trouble dinging the 4in steel circles at 200yds with the factory iron sights. All the gurly socialist AR-15 owners petitioned to disallow the big noisy mean ugly gun from being used anymore. I never bothered with those guys again.

I stupidly sold my Saiga .308. I wish I had it still and kick myself. Although I used the money to buy a VZ58, CZ P01, and. CZ PO7. If i find another .308 for a decent price, I’m snapping it up again.

That’s what I call well spent money.

Great post. Many thanks.

Excellent ‘conversion’ documented!

Many of us ‘Old Timers’ ditched the then available [198X] AR in favor of Chinese AKs….in 5.56!

I have three.

I’m jealous of the time to build one….50+ hours a week at work sucks!

I agree with this article 1000% I myself have built to AK-47s from kits both I had to complete the Demill process since they were only cut up in some eastern block country. There is a guy on YouTube Ginsboy2003 who had a great series Of video building an M70B1 which was my first build. I will pass the same advice as AK builders have to me that the M70B1 is not a great gun for a first build. The bulged reunions and extral dust cover catch button can be tricky to say the least. My second build an AK 63D from Hungary. It’s well worth building AK’s if you have access to the tools. After buying everything I needed I have to build more to justify the cost of tooling.

I’ve spoken to the guys at DGS a few times via Instagram. Good guys you should follow them and madmachinist.

Great write-up! Been following DGS on Instagram for a few months and I like the work they’ve been doing.

Welcome to the joy of #kalashlife