The 1911 .45 ACP combat pistol, invented by John Moses Browning, set the groundwork for most modern pistols. It’s a trusted combat handgun that has been used in more theaters of combat than any other weapon. The 1911 is still a popular choice as a self-defense/carry gun to this day, especially for concealed carry due to its slim profile.

So why does the pistol have a reputation for reliability issues? Despite its distinguished pedigree and extensive military service, the 1911s that you can buy from Wilson Combat, Kimber, Staccato, or Ruger, and Springfield Armory aren’t the same 1911 that was originally manufactured by Colt back in the day.

Small variations in manufacturing and assembly can cause some issues, but there are ways to minimize or completely eliminate problems you may be having with your 1911. Here are three ways to easily improve the reliability of your 1911 pistol…if it needs it.

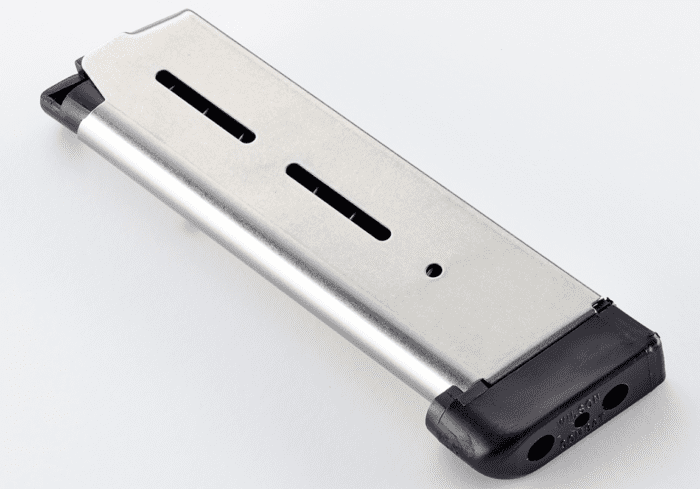

1 – Magazines

Magazines are a very big deal for the 1911. Many malfunctions can be caused and remedied with this seemingly simple piece of equipment. If you look at how a 1911 feeds ammunition, you’ll notice that the cartridge does a lot of work in the process.

The cartridge makes a sharp turn up in order to get in line with the barrel. Compare this to something like a GLOCK or other modern pistol. GLOCKs have the cartridge more in line with the barrel from the get-go, so the slide pushes it mostly straight in. The cartridge does less work so it’s less prone to getting hung up.

If the magazine’s lips let go of the cartridge too early, hold on too long, or the mag spring is too stiff or weak, this whole process can get hung up.

Then there’s magazine life. Some mags may work initially, but due to poor design/materials/manufacture, can wear out quickly. Wilson Combat, Tripps Research, and Chip McCormick are three magazine manufacturers that are known for their reliability. If you’re having feeding malfunctions with your 1911, pick up some magazines from one of these makers and see if that doesn’t solve the problem.

2 – Extractor

The extractor is probably the biggest culprit for most 1911 feeding malfunctions. It’s also one of the easiest things to fix since it doesn’t require any power tools.

Extractor tension is the first thing to look at. That’s the amount of force the extractor uses to grab a case. If the extractor has too much tension, the cartridge will have trouble getting under it, causing a stoppage.

Adjusting the tension is all about feel. If you pass a case through the extractor it should feel “magnetic,” not hard like a physical speed bump, but like moving a piece of metal past a magnet.

Another way to test for proper tension — and the way I prefer to do it — is to place a cartridge under the extractor and give the slide a few good shakes. The cartridge should fall out after 2 to 3 shakes. This also requires some “feel” on your end since a “good shake” can’t really be measured. As long as the case doesn’t fall free from gravity alone, or require real effort to remove, you should be okay.

You can adjust the tension of your extractor by bending it. I like using the slide, though there are plenty of other ways to do it.

Stick the hook end in and bend. Bend towards the hook for more grab and away for less. This is a light touch kinda thing. It doesn’t take much effort to adjust the tension, so make small adjustments. You may end up going back and forth between too much and too little a few times before finding the sweet spot. Be patient and gentle.

Here’s a good video from Wilson Combat that illustrates this.

Another thing to adjust on the extractor is the hook contours. You want the bottom edges to be rounded and smooth so the case is easily guided under the extractor. If the edges are sharp or square they can snag the brass.

Shaping the hook with a small needle file and sanding with high grit like 600 or higher will do it. If you can, polish it. Most modern extractors shouldn’t need this if the tension is set properly, but it won’t hurt. If I’m messing with the extractor, I’ll usually contour and polish the underside.

All of this pertains to feeding issues. If you’re having extraction/ejection issues, make sure the rake on the extractor hook is correct. It should be neutral or slightly positive. A negative rake may allow the case to slip off the extractor before it is extracted or ejected. If the extractor has a negative rake, squaring it may solve the problem, but it also may require a new extractor.

3 – Throat/Feedramp

This step requires some gunsmithing, so a Dremel or rotary tool of some sort is kinda required. If you don’t feel comfortable doing this yourself, have a good gunsmith do the work for you.

First, you want to properly throat the barrel. I recommend using a needle file or metal scraper for this step unless you are VERY confident in your Dremel skills. Most 1911 barrels have limited throats. This creates hard corners and edges that are good at snagging case mouths and bullets (see the right barrel in the above photo).

Match the existing angle and carry it up both sides so that edge is removed. Be VERY careful that you stay away from the opposing chamber wall. Don’t scratch that.

Before sanding and polishing, check the barrel throat to feed ramp gap. There should be a gap between where the feed ramp ends and the throat starts. This gap should be roughly .031″.

This can be tricky to measure, so don’t worry too much about whether you have “enough” gap and just make sure you have “some” gap. What you DON’T want to see is the throat line up perfectly with the feed ramp on the frame. That can create a snag point for incoming cartridges as well as make it harder for cartridges to get up and in.

Fix this by maintaining the existing angle on the throat and pushing it back a little. A “little” is the keyword here. Too far and you can have unsupported brass.

Once fully throated and the gap is set, polish the ramp to a mirror finish. This includes the feed ramp on the frame. Be sure to maintain the angles.

A great test to see if you were successful in your reliability improvement job is to feed an empty case. If your 1911 can feed an empty case, then feeding wadcutters, hollow points, and ball ammunition should be no problem.

Bonus tip: replace your recoil spring every 5000 rounds.

-/-/-/-/-

I want to point out that some of what I described — especially the throat work — is best left to a competent gunsmith. Even better, a gunsmith who specializes in 1911s. Messing with an extractor isn’t a big deal. It’s a cheap part that’s easily replaced. The barrel, on the other hand, isn’t so cheap or easy. Outside of giving it a good polish, I don’t recommend hacking away at your barrel unless you’re prepared to buy a new one and have a gunsmith fit it.

While these are the main things I would look at for improving your 1911’s reliability, everything else plays a part in the end result, too. If the bushing and barrel fit is off, it won’t run right or be accurate. If the trigger job is botched, you’ll get hammer follow or just have a horrendous trigger pull.

The thumb safety needs to be properly fit otherwise it will put unnecessary pressure on the sear or allow the gun to fire even when the safety is engaged. The grip safety should be tuned so it disengages with minimum movement. You can drastically change the feel of the gun by playing with the mainspring weight, recoil spring weight and the angle of the firing pin stop plate.

That being said, if you have a gun built by a good gunsmith or a good manufacturer from good parts, you will have a handgun that’s as reliable as any other and SIGNIFICANTLY more accurate. I’ve gotten 1.5-inch groups at 50 yards from a ransom rest. I’ve heard about 1911s doing 1-inch or better, though I have yet to see it myself. If you don’t think that level of accuracy matters, then you’ve never been held responsible for every bullet you’ve fired.

The 1911 platform is still the king in the competitive world and a go-to weapon system for many professional gunfighters for a lot of very good reasons.

Trick 4. replace it with a Gluck.

Came here to say that. Leaving satisfied.

Ditto. Never understood the 1911 cult.

Glocks float 1911’s hold the boat in place.

It’s a dual purpose tool.

I actually like the way a 1911 fits my hand.

But that is about as far as it goes.

jwm,

Why do I like a 1911 over a Glock?

I love the feel of a 1911 in my hand.

I like the added safety factor of a grip safety.

I like the single-action trigger.

I like their accuracy.

I like their grip-angle.

On that last point the 1911 grip-angle points naturally for me whereas the Glock grip-angle does not point naturally for me. (When I fast draw and present for instinctive “point-shooting”, my strong-hand elbow is slightly bent and I am immediately on target with the 1911 grip-angle. When I do that with the Glock grip-angle, I am off target until I recognize that and straighten my elbow.)

Don’t get me wrong, Glocks are very nice handguns. I mainly don’t like their grip-angle as well as their somewhat chunky grip and appearance.

Then again, I really like pretty much all handguns of all flavors–revolvers (both single-action and double-action) as well as semi-autos (striker-fired and especially hammer-fired).

I have Polymer80 “gluks”, with genuine OEM GLOCK uppers (slides + barrels). The P80 grip has the classic 1911 rake, which – as you state for yourself – just feels more natural in my hand. Best of both worlds, IMHO.

But I also have 1911s. I luv muh gluks, but I also luv muh ’11s.

Here is the 2 step system.

Step 1. Sell 1911

Step 2. Buy Glock

Texan, why not own both? I carried a 1911 in harms’s way for 25 years. I also carried Glocks and went through the Glock LE armour school at least three times. They’re both good pistols. Just different. Shuffling deck chairs on the Titanic.

And you can match your Glocks color to the rattlesnake you shoot🙂

possum, you still remember that?

The Possum is a whole lot sharper then the way he appears on TTAG..

I would not get a Dremel anywhere near the throat or the ramp. It is too easy to remove too much material, especially if you do not have a variable speed Dremel. Even easier is when the ramp is incorporated into the barrel itself, then all you need do is polish the ramp. When I got a Kimber, the ramp was contaminated with their KimPro coating, which I removed with fine and finer sand paper (wet dry stuff).

Replacing the spring should eliminate issues with the slide failing to go completely into battery. I had that problem with my Kimber, which the factory said was not an issue. Right. Anyway, I bought the correct 16 lb Wolff spring from Wolff, and the prblem was permanently solved.

I second the reliability of McCormick mags. Those are all I ever bought and I have all of them still. Wilson now owns McCormick, but the quality is the same as Wilson makes a solid mag as well. In fact, they make so many different 1911 mags figuring out which ones to buy is quite an issue!

Where is the “weird” portion of these tricks?

you have to do them in latex with cool whip or Hersheys syrup

So just another Tuesday.

And gluck her possum style

“And gluck her possum style”

Lord, I fear the day I come across a video of ‘Possum Style’… 🙂

Recoil spring does cause problems for sure. That’s the first thing I check now when a 1911 starts misbehaving.

Also an extractor to tight may cause your bullet to set back, as I learned when I didnt know about recoil springs wearing out and thought extractor, it may have been Mark N above? who suggested I may have tightened my extractor to much, if so thanx.

Good info in this article, thanx on that too.

My barrels rifling is just about worn out, next on tinker list is a barrel.

$$$$$, this Bidenomics is killing me.

in an old Army manual it was speaking of parts to be oiled, two drops of Whale oil here , and here.

How about that, Whale oil.

Whale oil is very special, it can withstand high temperatures and pressures. GM used whale oil in differentials in the ‘60s because nothing else would stand up.

No kidding.

I’d have never guessed.

pretty good read. figures you’d be writing about sperm one way or another…

https://environmentalhistory.org/2022/02/23/thar-she-blows-the-whale-oil-myth-surfaces/

It is amazing, you fucking people are so stupid that you let your emotional need to find fault with my posts blind you to reality.

And of course, because it’s always on your mind, you had to attempt a lame same-sex insult about ‘sperm’.

“In 1972, sperm whales breathed a huge sigh of relief because the Endangered Species Act was passed and these magnificent creatures could no longer be killed for their precious oil. In North America alone, 55 million pounds a year were being consumed. Little did anyone know that the car-driving public was about to learn a painful lesson — their automobiles’ transmissions were in big trouble without sperm whale oil.

Thanks to the critical role that sperm whale oil played in making automatic transmission fluids and gear oils, car transmissions routinely lasted for the life of vehicle. Once alternative ingredients had to be found, transmissions began failing at unheard-of rates. Before 1972, less than 1 million transmissions failed each year; without sperm whale oil, transmission failures exploded to more than 8 million by 1975.”

https://magazine.washington.edu/feature/the-innovation-file-solving-a-whale-of-a-problem/

The willful ignorance of right wing extremists is having a negative impact on the future of our country.

ITS THE BEST PISTOL EVER*

* = just as long as you get special mags for it

and take it to gunsmith two times

lol

I run GI mags just fine.

And as far as gunmsmithing the 1911 really isnt that hard to work on. That’s part of the fun.

How many tools does it take to completely tear down a stock1911? One of its bullets.

“3 Weird Tricks to Make Your 1911 .45 ACP Pistol More Reliable”

🤣

the title sounds like one of those ‘click bait’ video titles on youtube.

hello.

One other thing. I don’t care which semi-auto you’re shooting. Rifle or pistol, the first place to look for a malfunction is the magazine. Maintain them and don’t be afraid to throw them away.

Media deceptively uses a picture of a gun to report ‘mass knifing’ attack at Louisiana school.

I bought a Kimber years ago. Brand new out of the box the slide kept locking back while the magazine still had rounds left in it. I don’t recall the frequency, but it was enough to make the gun very unreliable. With a little investigation, I realized it was the magazine interface on the slide stop/release. It was too thick. A little filing (careful not to remove too much so as to still properly interface the magazine follower) and it never acted up again. I don’t have a 1911 today, but I sure have been thinking about acquiring one.

Break the thing in by shooting hundreds of rounds through it. Break-in is important as is extractor tension and quality magazines.

Don’t insert a round into the chamber and then drop the slide onto it unless you don’t care about maintaining the proper extractor tension. The weapon is not intended to be operated in this way so when the ejector hits the rim of the cartridge as the slide slams home it forces it to deform in a manner it was never intended to in regular operations. The magazine is situated so that only the bottom of the head underneath the extractor picks up the upper half of the cartridge and then as it ramps up it slides under the extractor without deforming it.

I know, and before I was schooled I used to do just that.

i noticed witness marks on the brass so i stopped.

One weird trick to make your 1911 pistol more reliable: sell it and get a glock 🙂

You’re so funny. I’m glad 3 other people didn’t make this joke before you.

Sale your Glock and by a tt33.

It points about the same.

Sale your Glock and by a tt33.

It points about the same.,,,,,*BUY* , I dudbt spell it rigt the first time

Got under your skin did it?

Accuracy requires close tolerances. Reliability generally requires looser tolerances to allow dirt and grit to fall out or through.

Two things I’d add: the Hi Power had some major improvements, the most important being:

Ramped barrel. This fixes a bunch of feed issues, as the nose of the round doesn’t have to transition between the frame and the barrel. Unfortunately, this requires a new frame or machining to accept a ramped barrel.

External extractor. Sig switched to this along with a few other manufacturers, and while it’s usually done to cut manufacturing costs, it is a much more foolproof system that doesn’t require adjustment.

I’ve EDC’d a Commander P14 for 4ish years now. Yes, it took quite a bit of fiddling and stoning to get everything to play nice. But having a weapon this accurate at my side is very comforting when considering the problems stray rounds can cause. Plus, 15 rounds of 45ACP in the gun and 16 in a spare mag is also comforting.

that cache is tough to argue with. always liked those warthogs.

ONe is none, two is one. I have both a 1911 and a Glock 19. Well, others also…

” I have two guns, one for each of you.”

Comparing a 1911 to a Glock is valid, but not for the reasons people think. A 1911 never had military specifications and still doesn’t. There is no one blueprint on them, like an M16/M14, Browning Bros literally machined them by eye and the factory simply used those parts to duplicate. It was literally manufacturing “art,” not the idealistic “cotton gin” manufacturing that still wasn’t actually happening.

When WWII came the Dept of War wanted more 1911’s but only Colt had some blueprints which weren’t exactly informative. Singer was contracted to figure out how to mass produce them – and, ironically, couldn’t meet their own standards. 25,000 were junked and just a few hundred were ever accepted. Remington Rand and Ithaca were the real beneficiaries, making millions of them – but they still required hand tweaking to get them to run reliably. 1911’s will not assemble with “drop in parts” and function – it takes trained, near gunsmith level skills to do it.

Glocks, on the other hand, were designed by modern engineers of the 80s who worked on modern machines with computer aided design and who understood modern fabrication methods on modern mass production machines. It’s a complete environment that allows all the parts to be made considering their variations when assembled and keeping those assembly dimension inside a tolerance – ie, “stacking tolerances.” That is a much larger and more complicated vision of manufacturing compared to the hand operated lathes and mills of Browning and Colts days. Each manufacturing plant can control all of its variables and actually manipulate them to create drop in parts for their assembly.

However, their parts may not fit another makers guns – there’s no universal blueprint unless it’s inside a makers industrial control. A EU Glock will still have some differences vs American. Any AR15 builder has experienced it, too, one upper lower fit may be so tight it takes tapping the pins with a small deadblow hammer to assemble, the next goes together like a Basic Training rattle trap. Ask us how we know. As for accuracy, tho, they can each do 2MOA.

This is the major reason why 1911’s and Glocks appear to be so different – the variables in manufacturing and control of assembly are historically very different. SIG recognizes this and it’s inherent in their manufacture to control and use it, which is how their reputation over the last 30 years has been stable. MIM parts? Most don’t know they are commonly used in automobile engines, or even if their favorite handgun has any – most don’t tear down and reassemble their guns to that degree. It’s the public who is usually 20-30 years out of date who makes those complaints.

In the ARMY I carried a 1911 daily, yes, I am that old. Liked my 1911 but the ones we had in the arms room were from the first world war and totally worn out, but they worked. I have multiple Glocks and all shoot / function fine. I would like to get another 1911, maybe a Springfield Armory, Any good?

probably. many here are biased against sa’s former lobbying practices.

if i were looking, i’d check out the new savage, consider something dan wesson and buy an ithaca. oh, sti review well here.

dead horse flogged.

I like my Glocks. I love my 1911. I carry my Sig.

When you run out of rifle ammo you can shoot a match grade 1911 at 200 yard plates, whereas thy crunchenticker will simply worry them. After I did that at SHOT range day there was a line to try. Multiple Glock, 1911, BHPs, revolvers…it’s sights and a good trigger that hits, not the magazine capacity, and unless you change Glock both you’ll shoot them like these public servants we see on uTube. Get off the pistol range every so often and prepare to fight a shooter with a rifle.

Everyone saying just buy a glock but the real answer is to buy a hi-point .45

Buy a quality 1911 from a reputable manufacturer and you’ll be trouble free for the rest of your days (assuming you clean it religiously).

Or get rid of that nickel plated sissy pistol and get yourself a Glock.